Operation, Controls and settings, M1 led 1 power switch output terminals xx on off – Lincoln Electric IM585 INVERTEC V-130-S User Manual

Page 13

B-2

OPERATION

B-2

Power Switch - Controls the power input to the

machine. This rocker switch is lighted. When power is

applied to the machine the light is on.

Knob M1 - Potentiometer used to set the value of the

current required by the welding process.

LED 1 - This LED will light up when:

A) The input supply voltage is not within limits

pre-set for correct operation.

V100-S: 95VAC to 125VAC*

V130-S: 200VAC to 255VAC*

B) The machine is overheated as detected by

the internal thermostat.

* Note that input voltages that exceed 20% of nominal

may cause internal damage to the machine.

Output Terminals - These quick disconnect terminals

provide connection points for the electrode and work

cables. For positive polarity welding connect the elec-

trode cable to the positive terminal and the work cable

to the negative terminal. To weld negative polarity

reverse the electrode and work cables.

INVERTEC® V100-S & V130-S

CONTROLS AND SETTINGS

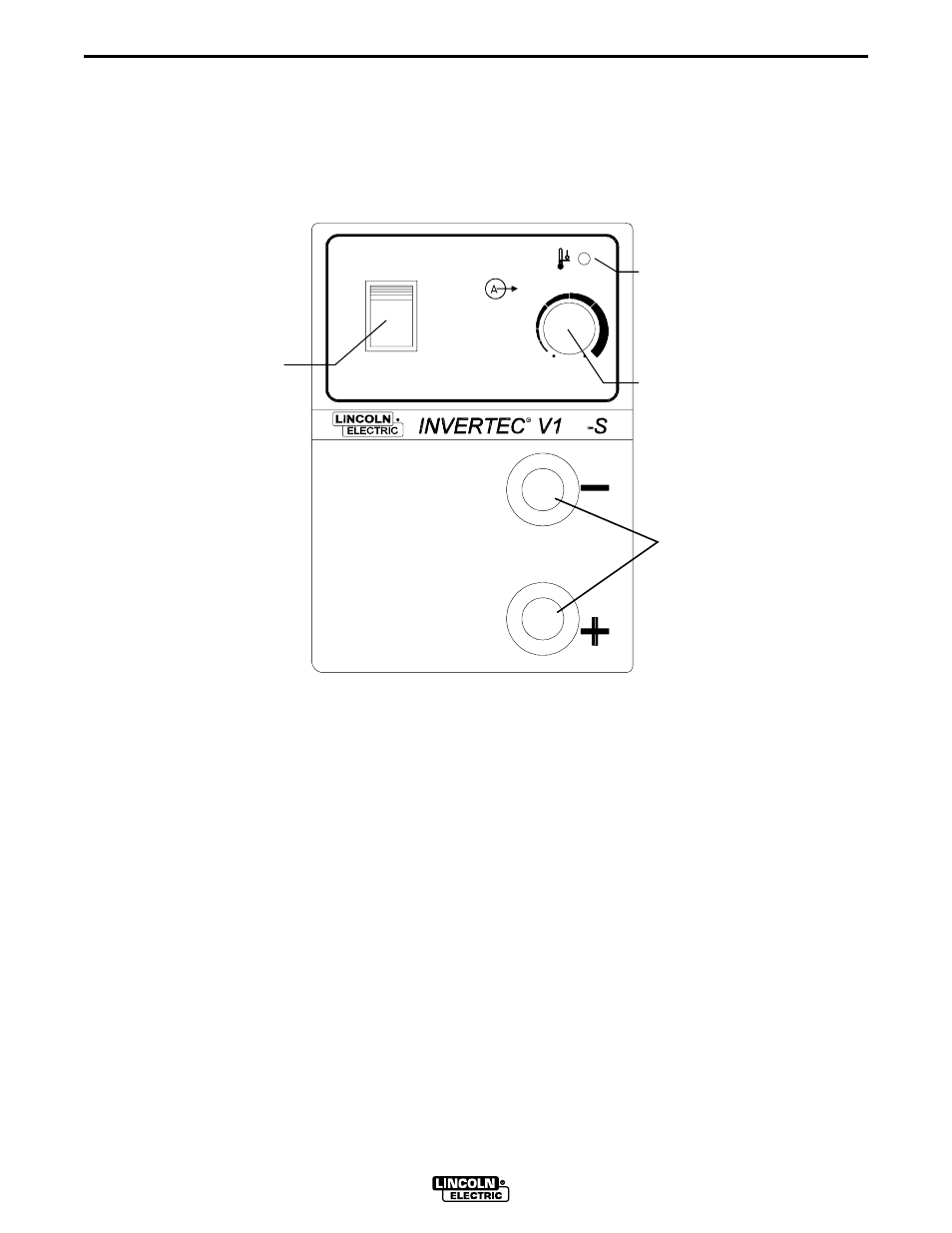

All operator controls and adjustments are located on the case front of the V100-S and V130-S machines. Refer to

Figure B.1 and the corresponding explanations.

FIGURE B.1 — CASE FRONT CONTROLS.

M1

LED 1

Power

Switch

Output

Terminals

XX

ON

OFF

XX

XX

XX

XX

XXX