Diagrams, Idealarc® dc-1000 – Lincoln Electric IM420 IDEALARC DC-1000 User Manual

Page 24

F-1

DIAGRAMS

F-1

IDEALARC® DC-1000

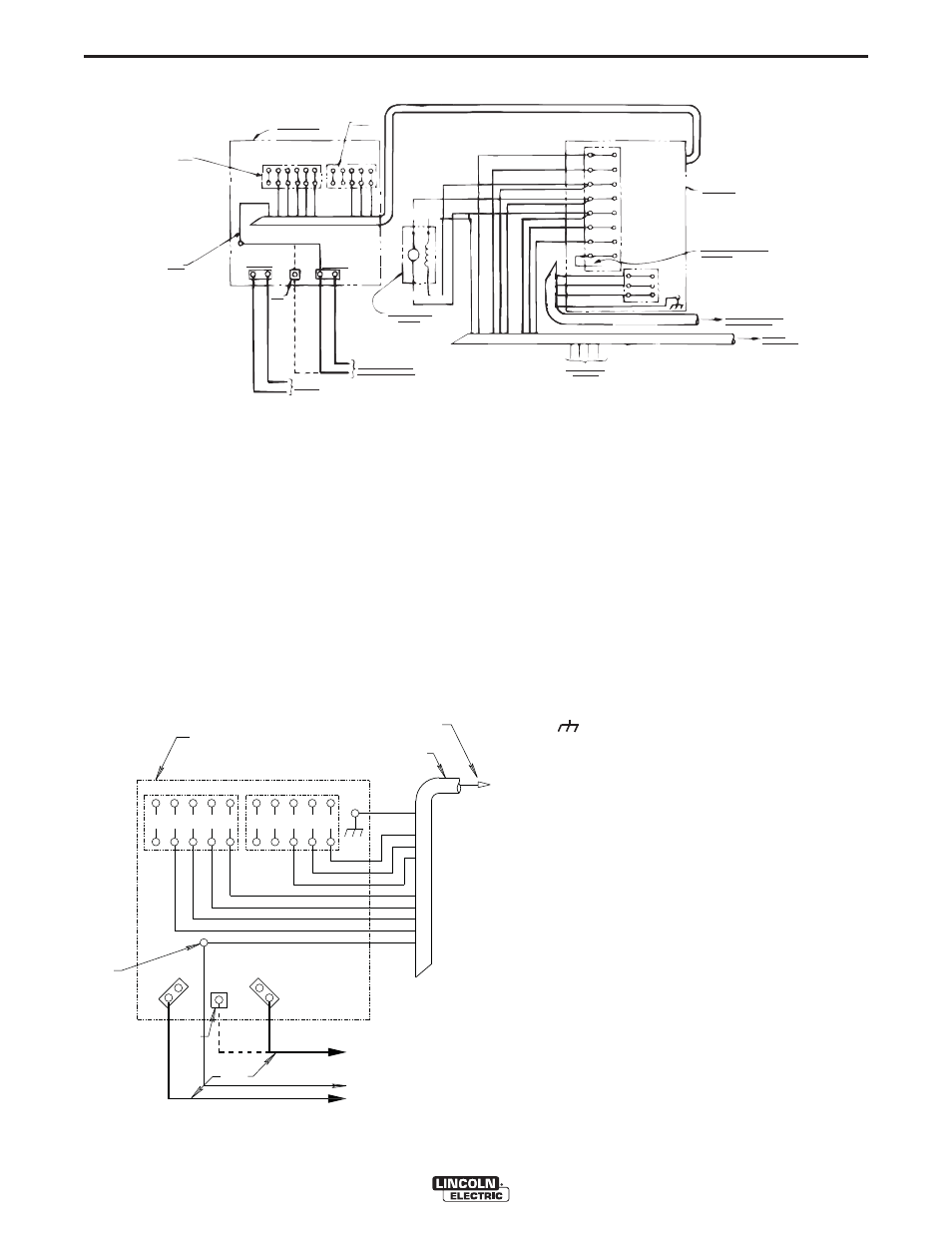

CONNECTION OF DC-1000 WITH NL OPTION KIT TO LAF-3 (Obsolete)

N.A. On all DC-1000 and DC-1500 units

with codes above 8234 extend lead

67 and connect it to the electrode

cable going to the automatic equip-

ment.

N.B. On DC-1500 units below code 8234

this is 67 and the LAF-3 #67 lead can

be connected either to the #67 termi-

nal or the electrode cable terminal as

shown. Terminal 82 not present on

later D.C. 1500ʼs and all DC-1000ʼs.

N.C. Terminals 73 and 74 not present on

earlier DC-1500ʼs.

N.D. Alternative 500 amp positive terminal

connection provided on DC-1000

models above code 9500 only.

This diagram shows the electrode connect-

ed positive. To change polarity, turn power

source off, reverse the electrode and work

leads at the power source and position the

switch on the power source and NL Option

Kit to the proper polarity. Also reverse the

leads on the back of the ammeter and volt-

meter in the LAF-3 control box.

Contactor drop out delay switch on the NL

Option Kit must be in the “On” position.

The 4/0 cables shown will handle up to

1000 amps at 80% duty cycle. For higher

currents or duty cycle add additional cables

to the power source output studs.

For best arc striking when connected to an

LAF-3 make the following change inside

the LAF-3 control unit. Remove the blue

jumper lead connected between #1 on the

coil of the main relay and #7 on the coil of

the transfer relay. (The main relay is the

upper right relay when facing the left end of

the control box. The transfer relay is just to

the left of the main relay.)

S17176

8-2-90F

CONNECTION OF DC-1000 TO LN-8

Connect the control cable ground lead to the frame terminal

marked near the power source terminal strip. The power

source must be properly grounded.

*If using an older control cable: Connect lead #75 to #75 on ter-

minal strip, connect lead #76 to #76 on terminal strip, connect

lead #77 to #77 on terminal strip.

N.A. Welding cables must be of proper capacity for the current

and duty cycle of immediate and future applications.

N.B. Extend lead 21 using #14 or larger insulated wire physi-

cally suitable for the installation. An S16586-[ ] remote

voltage sensing work lead is available for this purpose.

Connect it directly to the work piece keeping it electrically

separate from the welding work lead circuit and connec-

tion. For convenience, this extended #21 lead should be

taped to the welding work lead.

N.C. Tape up bolted connection.

N.D. Alternative 500 amp positive terminal connection provided

on DC-1000 models above code 9500 only.

Above diagram shows electrode connected positive. To change

polarity, turn power source off, reverse the electrode and work

leads at the power source and position the switch on power

source to proper polarity.

82

21

4

2

31 32

77

76

75

74

73

67

21

4

2

31 32

75 76

77

N.C.

POWER SOURCE

N.B.

N.A.

NEGATIVE

POSITIVE

N.D.

TO WORK

ELECTRODE CABLE TO

AUTOMATIC EQUIPMENT

35 VOLT CONTROL

EXCITER

21

1

6

4

2

1 10

21 32 31

18 45 29

5

TAPE UP LEADS

NOT USED

K775 REMOTE CONTROL

MOUNTED AT LAF-3

TO LAF-3

CONTROL BOX

CONNECT THE RED LEAD TO

TERMINAL 22

75

76

77

75

76

77

GND

22

31

32

21

10

1

2

4

NL OPTION

10

6

E

D

F

C

2 1

4

2

3 1 3 2

7 3 7 4

7 5 7 6 7 7

4

GN

D

P O W E R S O U R C E

N E G A T I V E

P O S I T I V E

2 1

N . A .

E L E C T R O D E C A B L E T O

T O W O R K

}

T O L N - 8 I N P U T

C A B L E P L U G

C O N T R O L C A B L E

3 2

3 1

2

C

B

A

} *

W I R E F E E D U N I T

N . D .

N . B . &

N . C .

M13321

8-2-90F