Installation – Lincoln Electric IM420 IDEALARC DC-1000 User Manual

Page 12

A-5

INSTALLATION

IDEALARC® DC-1000

A-5

OUTPUT CONNECTIONS

Output Studs

The output leads are connected to the output termi-

nals. The output terminals are located on the lower

case front and labeled “+” and “-”. There are 1000

amp rated “+” terminals on the right side, one 500

amp rated “+” terminal near the center and “-” termi-

nals on the left side. They are fully recessed to mini-

mize the possibility of accidental contact by an object

or a person. Strain relief is provided by the oval holes

in the base. The leads are run through these oval

holes before they are connected to the output termi-

nals.

The 1000 amp output connections provide the full

rated output range of the machine. See Table1 for

recommended DC-1000 cable sizes for combined

lengths of electrode and work cables.

The 500 amp output connections provide enhanced

lower current arc characteristics, especially for sub-

merged arc and GMAW procedures below 450 amps.

Auxiliary Power

This machine supplies the 115 volt, AC power needed

for operating wire feeding equipment. The power is

available from terminals #31 and #32 on the terminal

strip. An 8 amp slow blow fuse on the machine control

panel protects the auxiliary power from excessive

overloads. The circuit has a 1000 volt-ampere rating.

Control Cable Connection

Terminal strips with screw connections are located

behind the hinged door on the front of the power

source to make all the control cable connections for

operating wire feeding equipment. See the appropri-

ate connection diagram for exact instructions covering

the wire feeder being used.

With the DC-1000 turned off, the control cable from

the automatic wire feeding equipment is connected to

the terminal strip. A strain relief box connector is pro-

vided for access into the terminal strip section. A

chassis grounding screw is also provided below the

terminal strip marked with the symbol for connect-

ing the wire feeding equipment grounding wire. See

the appropriate connection diagram for the exact

instructions for the wire feeder being used. A spare

hole is provided for an additional box connector if

required.

Connecting for Air Carbon Arc:

a. Turn off all power.

b. Disconnect all wire feed unit control, electrode and

work leads.

c. Connect a jumper from 2-4 on terminal strip.

d. Place mode switch in the CV(I) position.

With the DC-1000 connected for air carbon arc weld-

ing, the output terminals will be energized at all times.

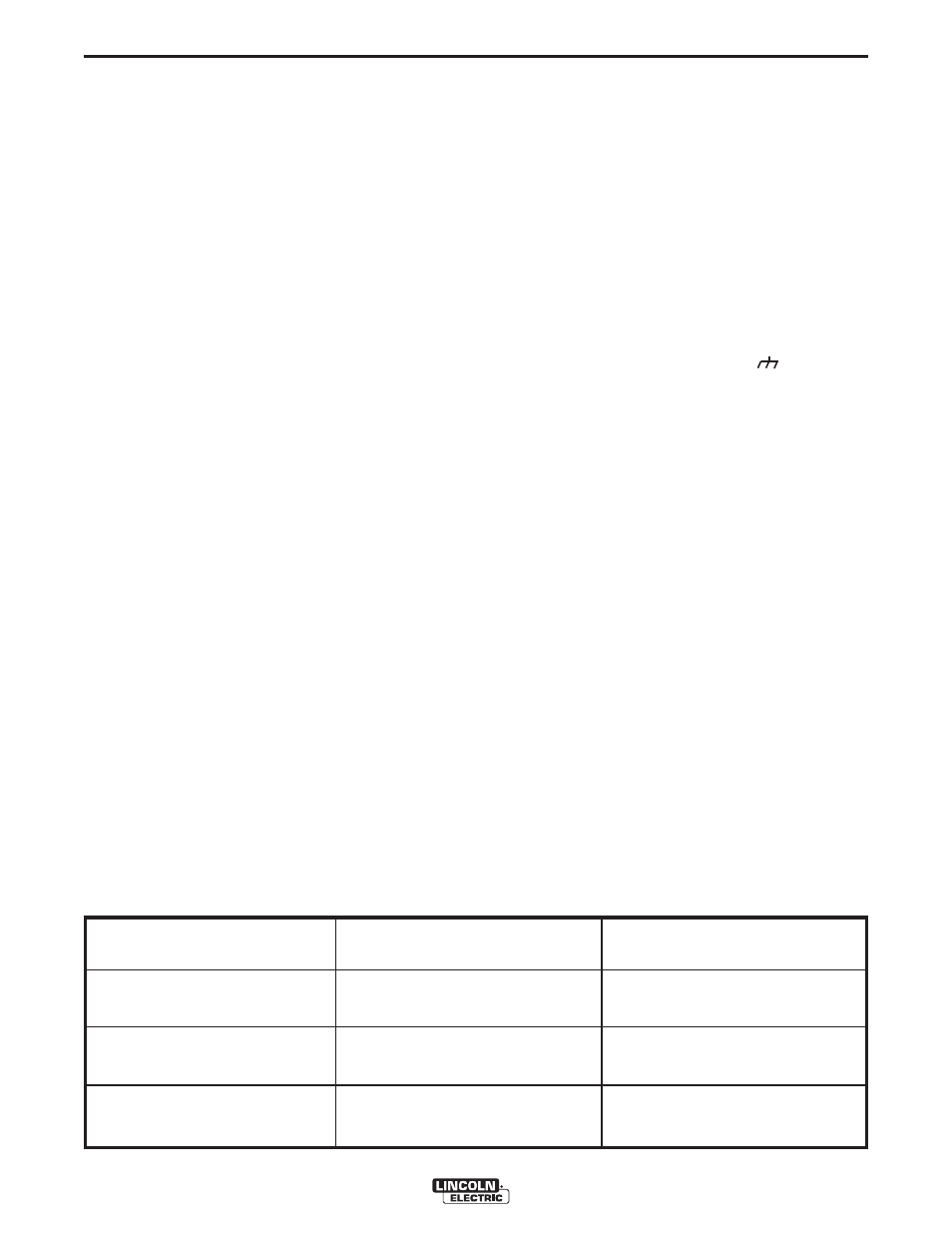

Cable Size

Parallel Cables

Cable Length

1/0 (53mm

2

)

3

3

3

Lengths up to 150 ft. (46m)

2/0 (67mm

2

)

150 ft.(46m) to 200 ft (61m)

3/0 (85mm

2

)

200 ft.(61m) to 250 ft.(76m)

TABLE 1

DC-1000 Cable Sizes for Combined Lengths of Copper Electrode and Work Cable

at 100% Duty Cycle

ELECTRODE, WORK AND #21 LEAD