Accessories – Lincoln Electric IM306 IDEALARC DC-600 User Manual

Page 26

C-2

ACCESSORIES

C-2

IDEALARC DC-600

5.

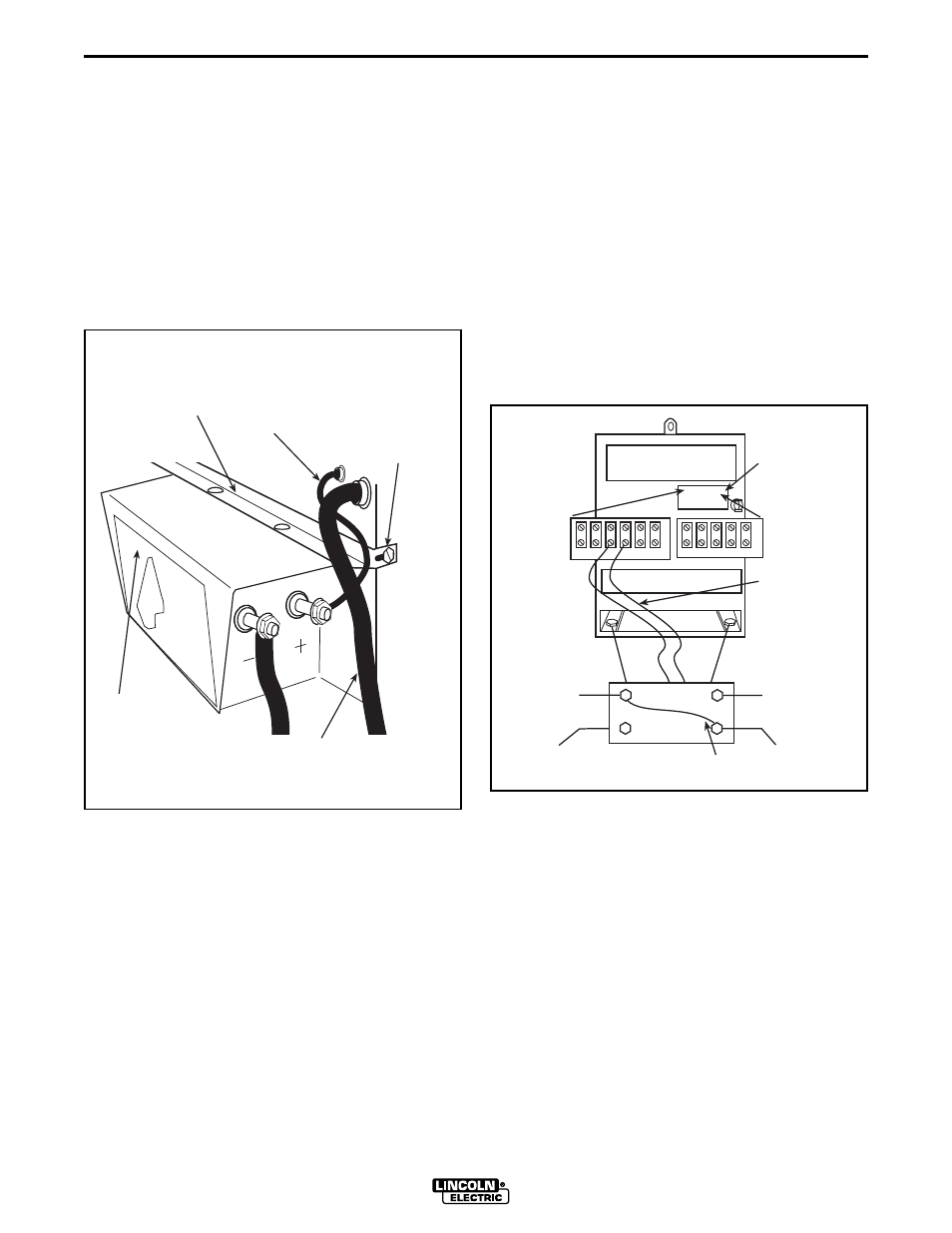

Attach the MULTI-PROCESS SWITCH bracket

across the front of the machine with the flange

down. Use the long, self-tapping screws and lock

washers provided. The bracket should be on the

outside of the side panel. See Figure C.3.

NOTE: If the machine does not have any holes in

the front of the machine, use the switch template

and drill two .153" diameter holes.

6.

Position the MULTI-PROCESS SWITCH at the

front of the machine. See Figure C.3.

FIGURE C.3 - ATTACHING THE MULTI-

PROCESS SWITCH BRACKET.

7.

Route the MULTI-PROCESS SWITCH control

leads through the strain-relief box connectors and

into the terminal strip. The wire feeder control

cable is routed through the strain-relief box con-

nector also. See Figure C.3.

8.

Connect the control leads from the MULTI-

PROCESS SWITCH to terminals #2 and #4 on

the IDEALARC DC-600's terminal strip.

9.

Position the MULTI-PROCESS SWITCH flush

with the front of the machine about 2" lower than

the bracket. Slide the switch straight up to the

bracket.

10. Check that the bottom of the switch is hooked

behind the top of the bottom louver.

11. Connect the right cable from the MULTI-

PROCESS SWITCH (facing the front of the

machine) to the IDEALARC DC-600 positive (+)

output terminal. See Figure C.4.

FIGURE C.4 - MULTI-PROCESS SWITCH

CABLE CONNECTIONS.

12. Connect the left cable from the MULTI-PROCESS

SWITCH (facing the front of the machine) to the

IDEALARC DC-600 negative (-) output terminal.

See Figure C.4.

MULTI-

PROCESS

SWITCH

BRACKET

WIRE FEED

CONTROL

CABLE

MULTI-

PROCESS

SWITCH

CONTROL

LEADS

SELF TAPPING

SCREWS

(DRILL .153"

HOLE IF

NEEDED)

WORK

CABLE

WORK

ELECTRODES

21 4

2 31 32

75 76 77 80 81

TERMINAL

STRIP

POSITIVE (+)

OUTPUT

STUD

–

+

NEGATIVE (–)

OUTPUT

STUD

ELECTRODE

CABLE

WORK

CABLE

ELECTRODE

CABLE

JUMPER (IF NEEDED

SEE INSTRUCTIONS)

+

CONTROL

LEADS

STICK AIR/CARBON

ARC WELDING

EQUIPMENT

WIRE

FEEDER