Stuart Turner Monsoon U2.0 bar Single User Manual

Page 11

- 11 -

Cont ...

3.13

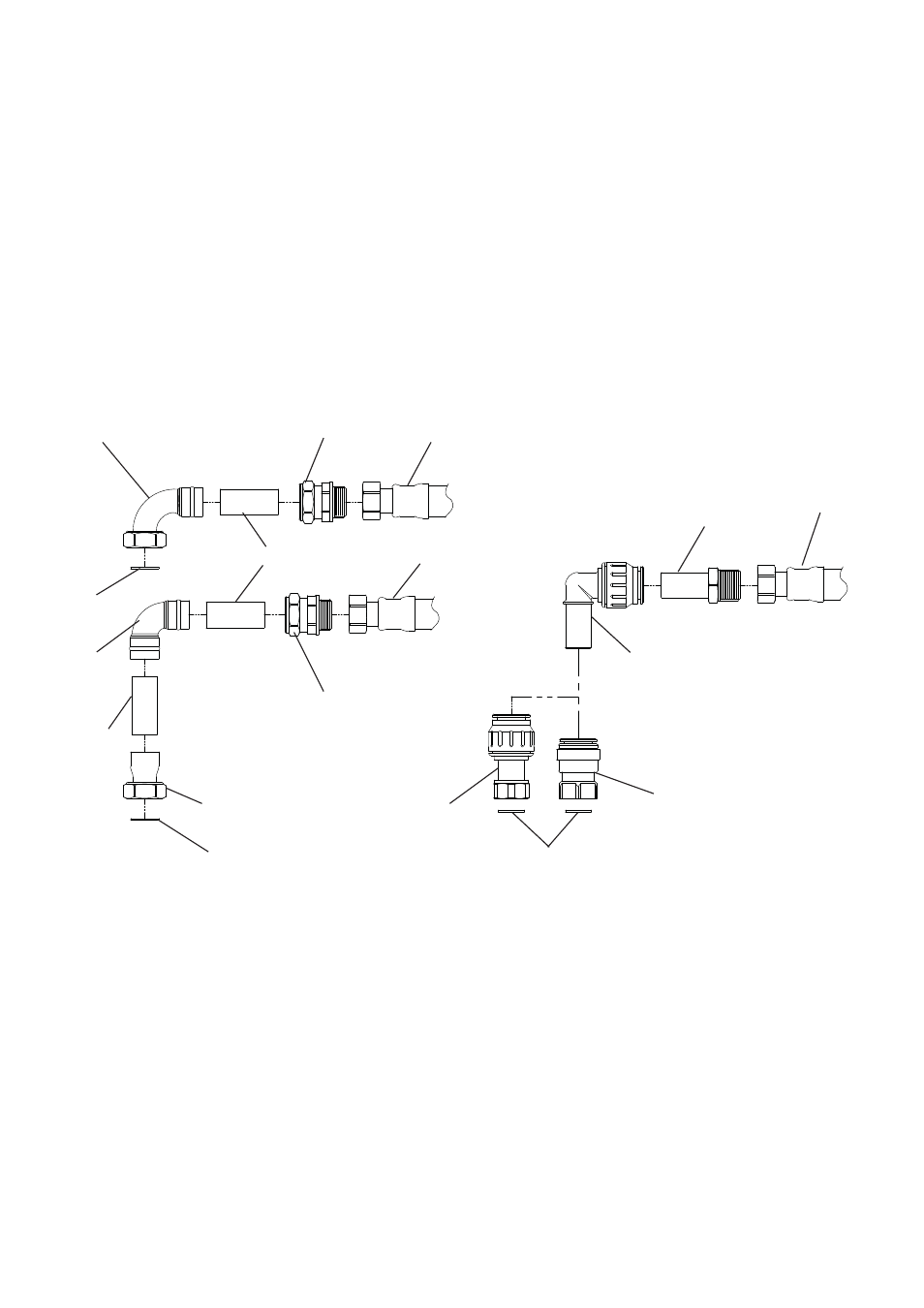

Typical Low Level Installation:

In certain installations it may be necessary to install a 90° bend on the inlet or

outlet connections of the pump before the flexible hose to accommodate a low

level

installation.

Below are some preferred connection options. All connections seal on the pump

body using a fibre or rubber sealing washer. Tap connector fittings should be

used which must be of an appropriate pressure and temperature rating.

It is essential when using any of the fittings shown below, that a correct water

tight seal is obtained between the pump body and selected fitting and also

the flexible hose and selected fitting. If in doubt contact the fitting manufacturer

and confirm compatibility with the connection to be sealed.

Carefully check connections and pipework for leaks whilst pump running and

stationary before leaving the installation unattended.

If you have any concern either about using push-in fittings or should the joint

leak on final test isolate the water supplies and contact Pump Assist on

0844 98 000 97.

Fig. 10

G ¾ female x 22 mm

elbow tap connector.

Fibre washer.

22 mm

elbow.

22 mm

copper

pipe

Fibre washer.

G ¾ female x 22 mm

tap connector.

22 mm compression to

G ¾ male.

22 mm copper pipe.

G ¾ female flexible hose

(supplied in kit).

22 mm compression to

G ¾ male.

G ¾ female flexible hose

(supplied in kit).

22 mm to G¾

male.

G ¾ female

flexible hose

(supplied in

kit).

22 mm stem elbow.

G ¾ female x 22 mm tap

connector with rubber

sealing washer.

Sealing washer (sometimes

captured in fitting)

G ¾ female x 22 mm

swivel tap connector

with rubber sealing

washer.