Sequence of operation – MAHLE RTI CSC10 User Manual

Page 5

- 4 -

Sequence of Operation

The CSC10R is a device designed to perform quick and simple

engine coolant changes on automobiles and light trucks. When

properly operated, this Quick Change can be accomplished in as

little as ten minutes. The following is the normal sequence of

operation for the CSC10R. Refer to the "Performing A Quick

Change" and "Using The Recycling Center" section of this manual

for complete instructions before operating your unit.

PREPARE FOR THE QUICK CHANGE - A

vehicle is pulled into the service area and the CSC10R is

positioned. An appropriate amount of new recycled coolant is

mixed in the CSC10R Fill Bucket.

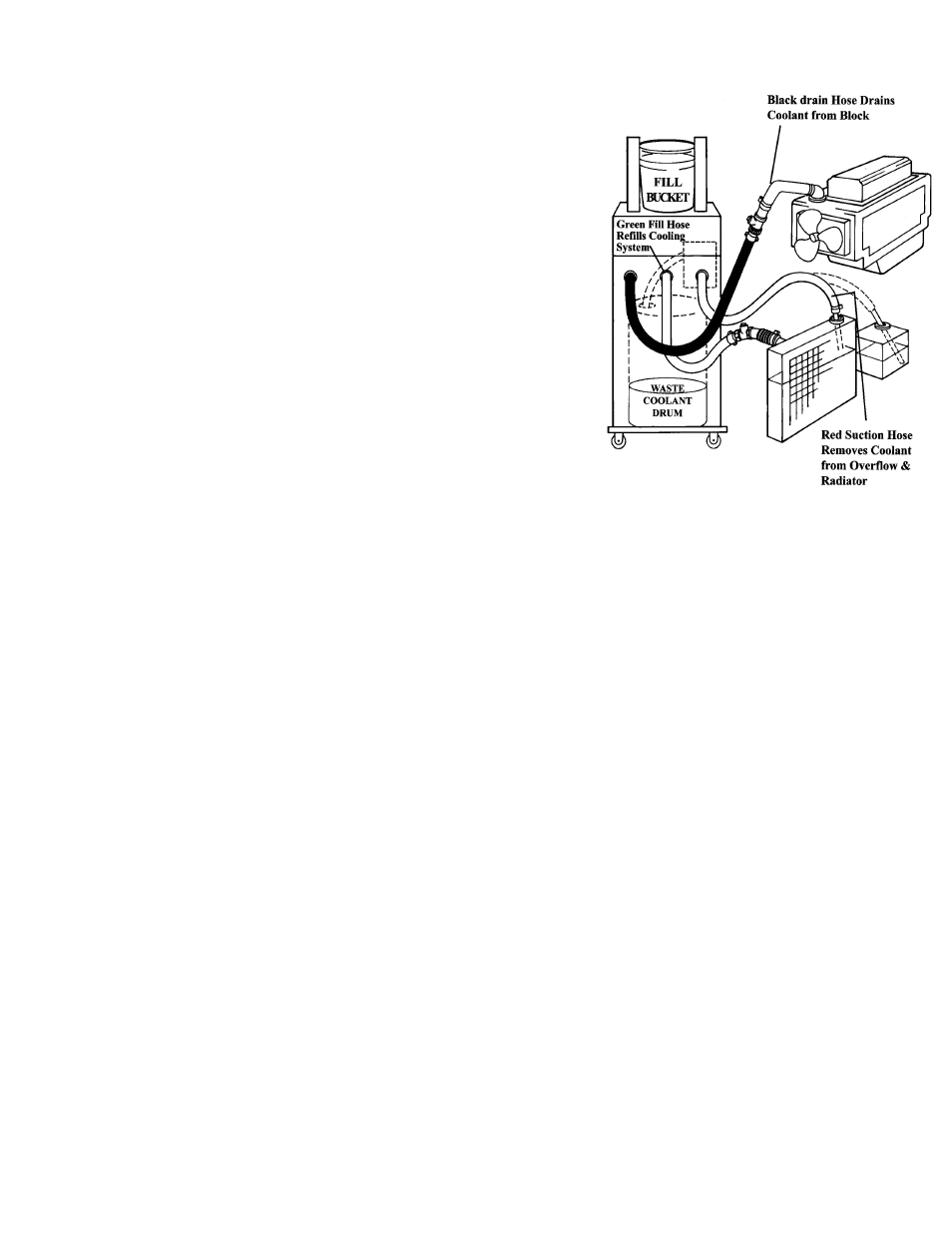

USE THE EVACUATION PUMP - Waste coolant is removed

from the vehicle's radiator and overflow bottle using the CSC10R

Suction Hose.

ATTACH THE CSC10R - The GREEN Fill Hose and BLACK Drain hose are attached to the vehicle's

cooling system through a removed upper radiator hose. No hose cutting or tees are required.

PERFORM THE QUICK CHANGE - While the Drain Valve on the BLACK Drain Hose is closed,

the Fill Valve on the GREEN Fill Hose is opened and the vehicle's engine started. The Drain Valve is

opened, and the level in the Fill Bucket will drop as the new coolant displaces the waste coolant. the

waste coolant drains through the BLACK Drain Hose and into the Waste Coolant Drum in the rear of

the unit. When only two quarts of new coolant remain in the CSC10R Fill Bucket, the Fill and Drain

Valves are closed, and the vehicle's engine is turned off.

DISCONNECT THE CSC10R - The CSC10R is removed from the vehicle and the vehicles's radiator

hose is re-attached.

TOP OFF - The radiator and overflow bottle are filled to the proper levels using the GREEN Fill Hose.

The engine is started to check for leaks.

RECYCLE - Once the CSC10R Waste Coolant Drum contains twelve to fifteen gallons of waste

coolant, it is time to recycle. The valve on the YELLOW Hose is opened and inserted into the Clean

Coolant Drum. The Process Switch is turned on, and in less than ten minutes, the filtering process is

complete.

REINHIBIT - After the filtering cycle is complete, the recycled coolant is mixed with water or

antifreeze to obtain the desired freeze/boil protection. RTI's Automotive Reinhibitor for CSC10R is

added to adjust the pH and to replenish depleted corrosion inhibitors, buffers, anti-foaming agents, and

dyes. This process produces a quality recycled coolant that meets or exceeds ASTM standards.