8preliminary runout compensation adjustment – MAHLE RTI BRC440 User Manual

Page 11

Page 9

8

Preliminary Runout Compensation Adjustment

(Continued)

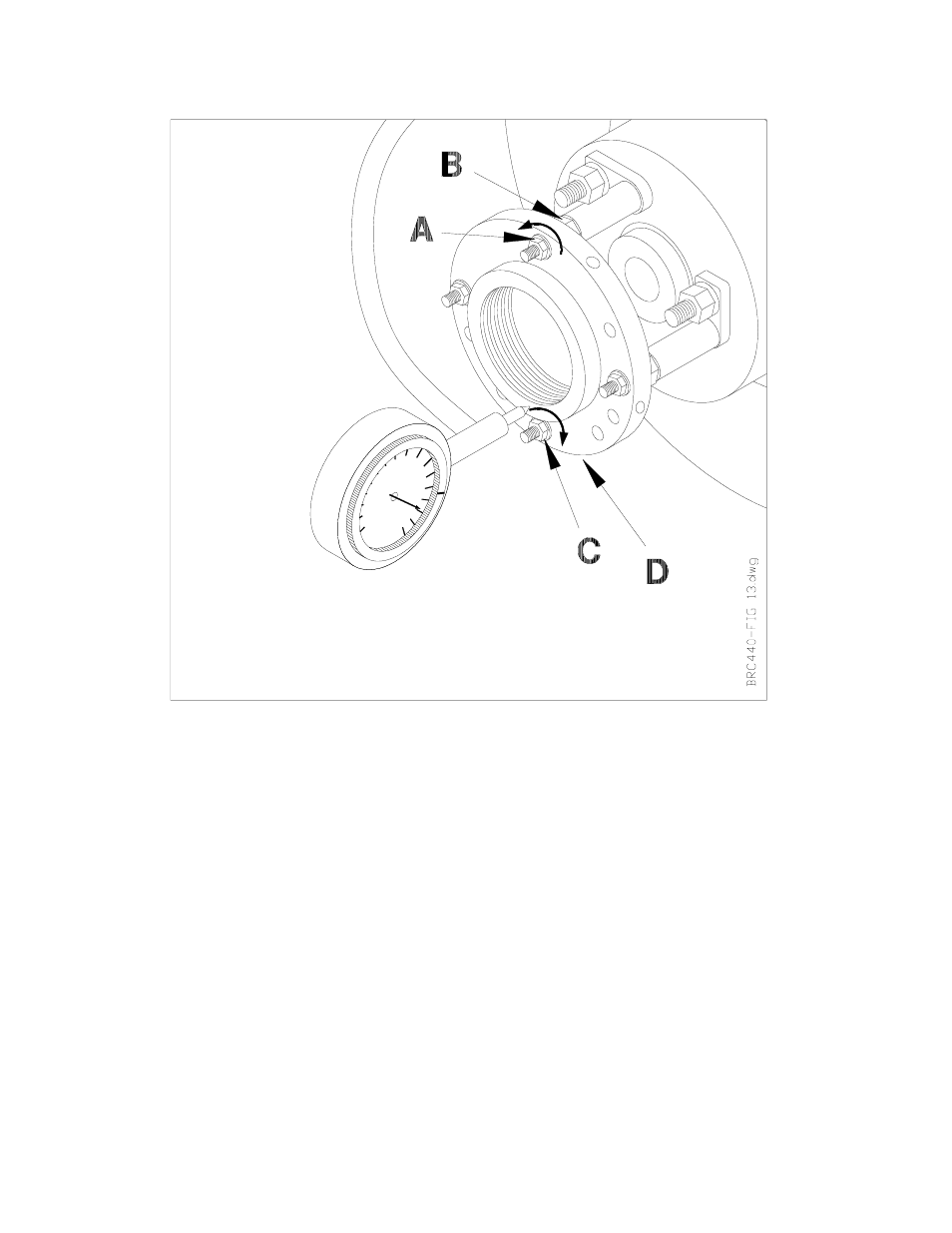

8.3 Rotate the Centering Plate until the Dial Indicator needle is at the largest number of

the total swing, as shown.

8.4 Nuts on the two cranks are next adjusted to move the needle one-half the distance

between the present reading and the mark on the bezel.

8.4.1

Slightly turn (1/16 rotation or less) small nut A in direction of arrow.

8.4.2

Tighten large nut B by turning in direction of arrow.

8.4.3

Slightly turn (1/16 rotation) large nut D (not visible) in the direction of arrow.

8.4.4

Tighten small nut C by turning in direction of arrow.

8.5 The needle will have moved towards the mark on the bezel, hopefully about one-half

the distance from its starting point. Colored bands on the Cranks can be used to keep

track of position if the Centering Plate must be turned to aid in adjusting the nuts.

8.6 Repeat Steps 8.3 and 8.4 until the TOTAL swing of the needle during a 360 degree

rotation of the Centering Plate is 0.004 in. (0.1 mm) or less. Near zero swing will make

the final adjustments, after the lathe is mounted, much easier.