Installation, 1 mechanical considerations, 2 fast loop line size and response times – Yokogawa Advanced Reflux Sampler User Manual

Page 9

9

All Rights Reserved. Copyright © 2011, Yokogawa Electric Corporation. Subject to change without notice.

April 2011

IM 11A00V01-01E-A

5.1 Mechanical Considerations

Typically, the YARS will be subject to large vibration conditions and therefore a sound mechanical installation is required.

While flange mounting to the customer supplied process isolation valve provides an installation, it is also recommended

that the upper section of the YARS be secured mechanically. The heat exchanger and controller give the YARS ‘top-heavy’

properties that should be considered during installation.

It is also desirable to have ready access to the unit such that routine maintenance checks can be made on the operation

of the unit in a safe manner.

Ensure that an appropriate gasket is used between the flange mounting faces and when tightening the flange mounting

bolts to the process isolation valve, please ensure that the correct torque is applied (typically 100 foot pounds for a 2”

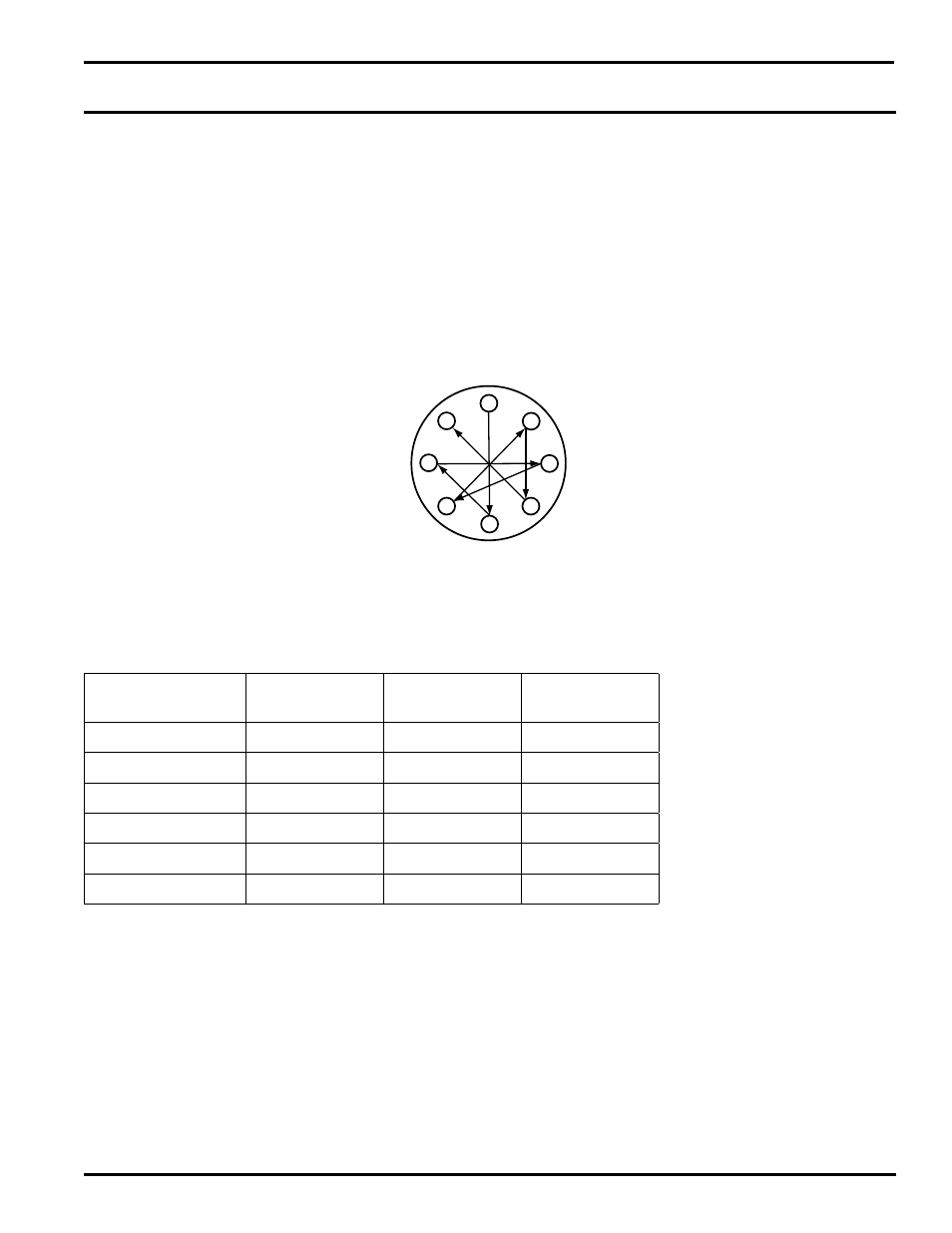

300# flange). As with any flanged bolt tightening, ensure that the correct sequence of tightening is followed (typically as

shown below):

1

6

4

7

2

5

3

8

5.2 Fast Loop Line Size and Response Times

The following table may be used when estimating sample line sizes, response times and resultant pressure drop through

the line. These calculations are based on a typical ethylene cracked gas effluent sample and should be used for estimating

purposes only:

Sample Line Size

Stainless Tube

Sample Line

Length

Sample Flow

Rate Lts/min

Response Time

Seconds

¼”

200’

1.5

39

¼

200’

3

19

¼

200’

4.5

13

3

/

8

”

200’

1.5

108

3

/

8

”

200’

3

54

3

/

8

”

200’

4.5

34

5. INSTALLATION