Warning, Caution, Vi. programming – Yokogawa AC8 Calibration Units User Manual

Page 9: Vii. set-up procedures

9

IM 11M6D2-02E-A

11. Turn the block solenoid and the

zero/span solenoid to

the

normal position.

WARNING

If reference air is used during calibration, the reference air must

remain ON after calibration.

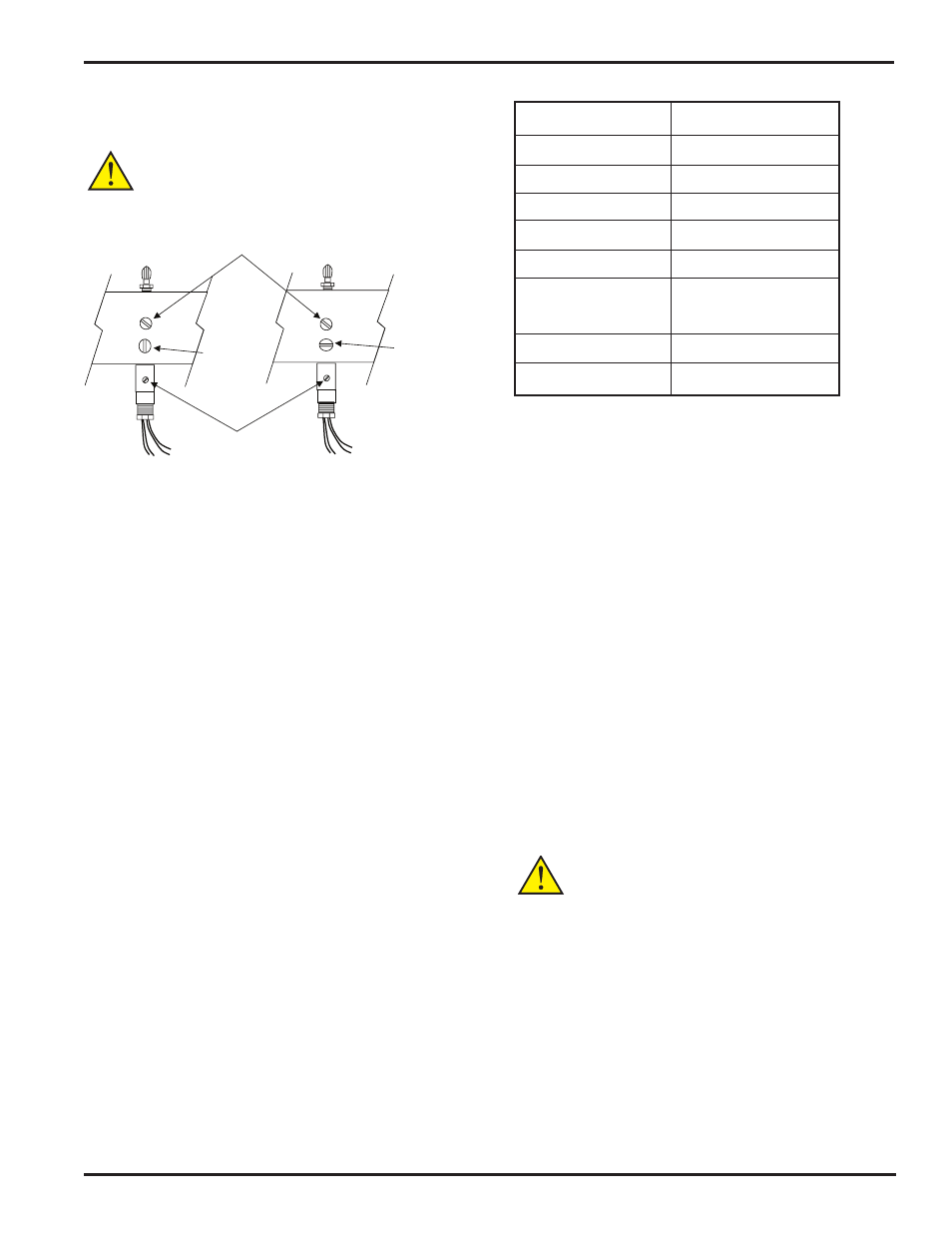

NORMAL OPERATION

OVERRIDE

MOUNTING SCREW

FLOW ADJUSTMENT SCREW (PRESET)

FOR NORMAL

OPERATION THE

MANUAL

OVERRIDE SCREW

MUST BE IN THE

VERTICAL

POSITION

FOR OVERRIDE

THE MANUAL

OVERRIDE SCREW

MUST BE IN THE

HORIZONTAL

POSITION

Figure 5.3: Typical Channel Solenoid

5.4 CAL CHECK

The purpose of performing a cal check at this time is to con-

firm that the calibration gas and reference air are plumbed

correctly for each probe, along with confirming that enough

time was allowed for the cal gas to flow at the probe’s cell

tip. Refer to the AV550G Instruction Manual for calibration

codes and procedures.

VI. PROGRAMMING

All programming for the AV550G Averaging Unit is done

through the display module. Please refer to the AV550G

Instruction Manual, IM 11M12D01-01E, Section 9 for ad-

ditional details. The following is a brief description of setup

procedures.

The ZR22G Probe is calibrated by applying two known gas

standards. In most applications the zero gas is around 1%

oxygen with the balance nitrogen. The span gas is instru-

ment air (20.95 % oxygen).

The zero gas concentration must be certified so the exact

concentration can be programmed into the AV550G memory.

Calibration values required for full auto-calibration operations

are stored in the menu of the AV550G.

For additional information refer to Chapter 8 of the AV550G

manual for a full explanation of all parameters.

Shipping time default setting for zero gas is 1% oxygen and

for span gas is 21%. Figure 6.1

Item

Initial value

Mode

Manual

Points

Span-Zero

Zero gas conc.

1.00%

Span gas con.

21.00%

Hold time

3 min. 00 sec.

Cal. time

3 min. 00 sec.

Interval

1 days 00 hrs

Starting date

yy01mm01dd01

Starting time

hh00mm00

Figure 6.1

VII. SET-UP PROCEDURES

7.1 Mode

There are three calibration modes (for zero and span calibra-

tion: manual mode, semi-automatic mode (started from the

display or started by contact input) using preset calibration

time and stabilization (settling) time, and auto calibration

at preset intervals. Restrictions related to each mode are

described here.

-When [Manual Mode] is selected:

In this mode, only Manual calibration can be performed.

(Contact input used to start semi-auto calibration has no ef-

fect). Auto calibration does not start at auto calibration start

time.

-When [Semi-Auto Mode] is selected:

In this mode, manual calibration or semi-automatic

calibration can be performed.

Auto calibration does not start at auto calibration

start time.

-When [Auto Mode] is selected:

Any calibration mode is valid.

CAUTION

Indication check mode of [Auto] cannot coexist with [Auto]

Calibration mode. Therefore, if the mode of indication Check is

set to [Auto], you cannot set the mode of Calibration to [Auto],

and vice versa.

the [Execution/Setup] display appears. Select [Maintenance].

2) From the [Maintenance] display, select [CalibrationSetup]

the [Mode] amd you can selct Manual, Semi-Auto, or Auto in

the selection drop down that appears. Figure 7.1.