Warning – Yokogawa AC8 Calibration Units User Manual

Page 8

8

IM 11M6D2-02E-A

5.3 BALANCING PRESSURE DROPS IN THE CAL LINES

For accurate calibrations, the auto cal system must provide a

fixed flow of zero gas and span gas (0.6 LPM pr 600cc/min).

To do this, the pressure drop from the AC4/AC8 to each

probe must be the same regardless of the length of tubing

run or number of probes. To balance the pressure drops,

perform the following steps:

NOTE

Perform all adjustments with a flat tip screwdriver.

1. Ensure gas and instrument air are plumbed to the auto cal

unit. Pressure should be set at 20 psig ± 2 psig.

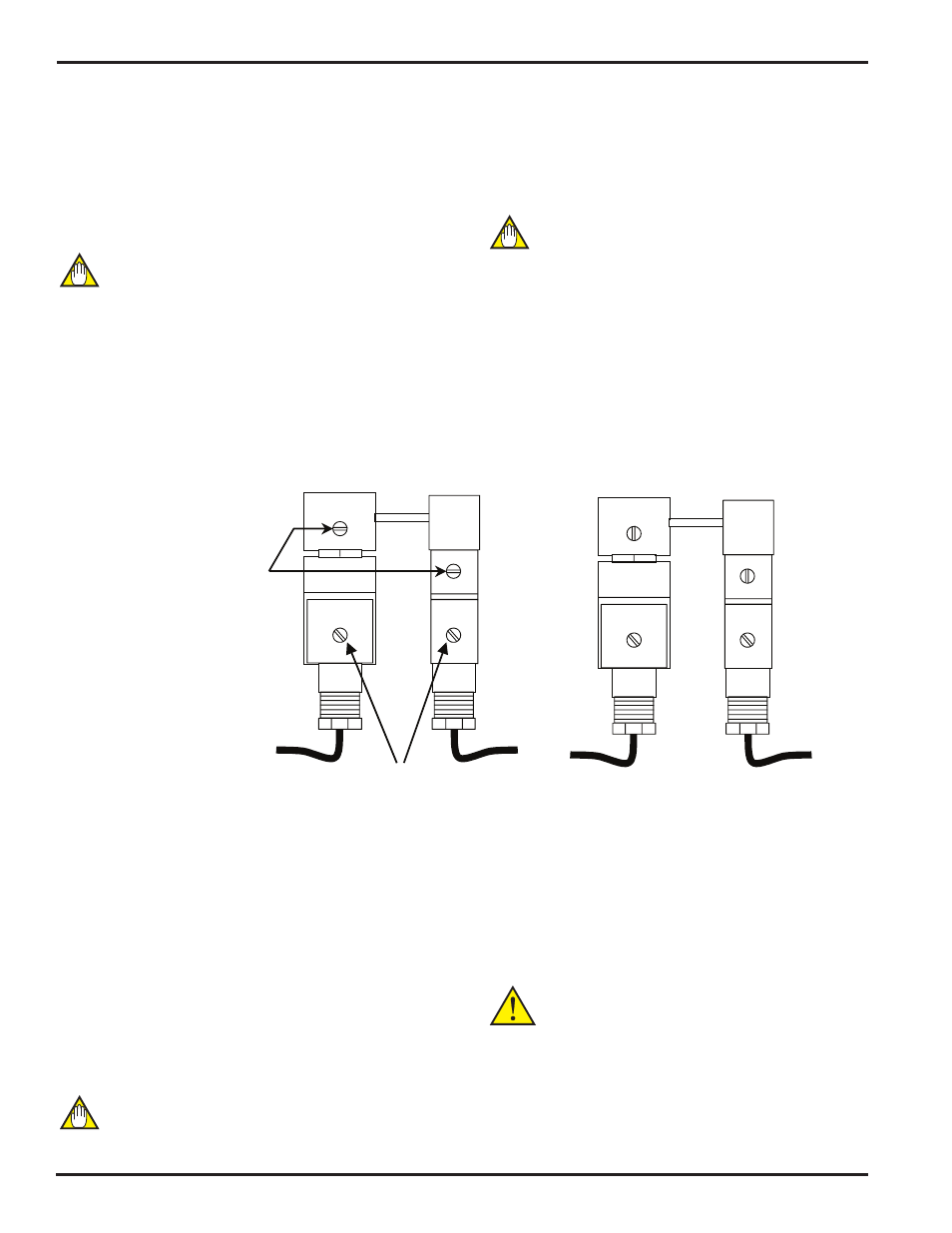

2. Locate the block solenoid shown in Figures 5.1 and 5.3.

Using a flat tip screwdriver, turn the manual override screw

on the block solenoid to the vertical position, as shown in

Figure 5.2.

ZERO/SPAN

SOLENOID

BLOCK

SOLENOID

MOUNTING

SCREWS

NORMAL

FOR NORMAL OPERATION AND

MANUAL OVERIDE, SCREWS

MUST BE IN THE POSITIONS

SHOWN

ZERO/SPAN

SOLENOID

BLOCK

SOLENOID

OVERRIDE

Figure 5.2: Zero and Block Solenoid

3. Locate the

cal gas flow meter in Figure 5.1. Turn the

black adjuster knob to the maximum open position. This fully

opens the cal gas regulator, allowing precise adjustments of

flow rates.

4. Locate the

channel solenoid valve for the probe with the

longest tubing run in Figure 5.1. Turn the manual override

screw to the horizontal, or ON position. Refer to Figure 5.3.

5. Each channel has its own flow adjustment screw located

on the

channel solenoid valve as shown in Figure 5.3. Ad-

just the flow adjustment screw for the probe so that the flow

rate shown on the cal gas flow meter is 1 LPM (1000 cc/min).

NOTE

DO NOT use the cal gas flow meter’s adjustment knob to make

this flow rate adjustment. If necessary, increase the air pres-

sure.

6. Turn the manual override on the channel solenoid for the

probe to the

OFF (normal) position.

7. Repeat steps 4, 5, and 6 for the remainder of the probes

that are being used.

NOTE

DO NOT use the cal gas flow meter’s adjustment knob to make

this flow rate adjustment. Use the individual channel’s flow

adjustment screw to adjust for varying pressure drops in the

tubing runs.

8. After all flow rates have been set manually to 1 LPM, turn

the channel solenoid for the probe with the longest tubing

run back ON to the manual override position – making sure

all others are

OFF (normal position shown in Figure 5.3). Turn

the cal gas flow meter’s adjustment knob to 0.6 LPM (600cc/

min).

9. Turn the

manual override screw (Figure 5.3) on the zero/

span solenoid (three way solenoid) to the 90º position. This

starts the flow of the zero gas. Adjust the

needle valve to

the left of the three-way solenoid so that the flow rate is 0.6

LPM (600cc/min). If 0.6 LPM is difficult to obtain, it will be

necessary to slightly increase the zero gas pressure to the

unit.

WARNING

Do not adjust the cal gas flow meter or the flow adjustment

screw on the individual channel solenoids.

10. Confirm that all

channel solenoid overrides for all used

probed are turned back to the normal position as shown in

Figure 5.3.