Important, Wmime?u – Yokogawa AC8 Calibration Units User Manual

Page 5

5

IM 11M6D2-02E-A

3.4 PIPING

PCDE?Q

A?J

E?Q

/-2ĥ

DCK?JCLNR

/-2ĥ

DCK?JCLNR

WMIME?U?

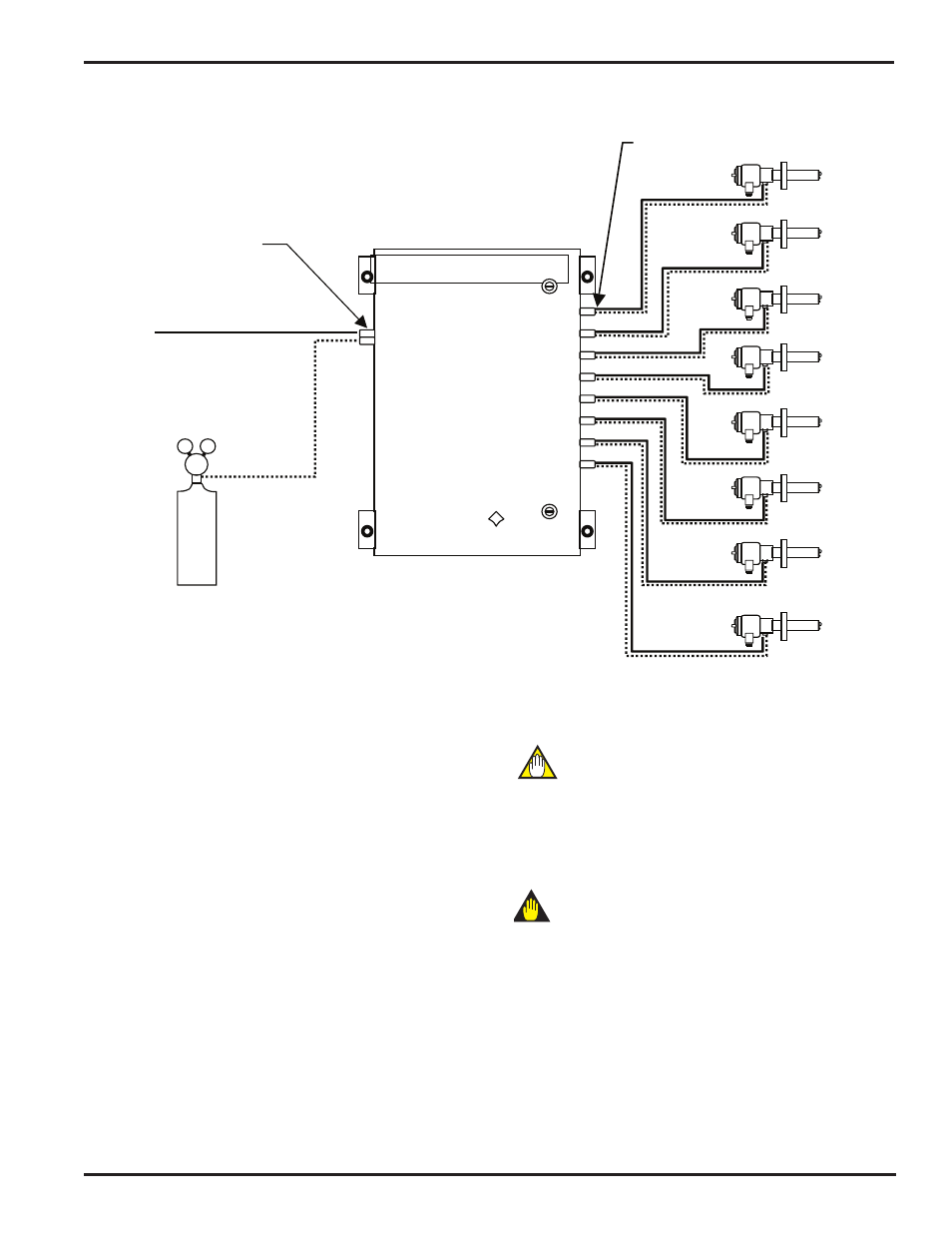

O2 CALIBRATION SYSTEM

LCK?2V

INSTRUMENT AIR

ZERO GAS

35 psig MAX

PROBE 1

PROBE 2

PROBE 3

PROBE 4

PROBE 5

PROBE 6

PROBE 7

PROBE 8

Figure 3.2

Piping Gases to the Auto Cal Unit

Piping (or tubing) is required from the instrument air line and

zero gas cylinder to the calibration unit. Standard tubing is _”

O.D. (Outside Diameter) copper or stainless steel. Stainless

steel is preferred, as it is less likely to develop leaks. The

separate tubing for both the instrument air and zero gas are

connected to the two separate 1/4” FNPT brass or stainless

fittings on the

LEFT side of the calibration unit.

Piping Gases to ZR22 Probes

The tubing to the ZR22 probes is run from the

RIGHT side of

the calibration unit to each of the ZR22 probes as shown in

Figure 2. Quarter inch (1/4”) tubing should be used between

the auto cal unit and the probes. It is important to note

1)

the reference air tubing is connected to the REF IN port

at the probe; 2) cal gas tubing is connected to the CAL

IN port on the probe. The REF IN and CAL GAS ports are

located on the bottom of the ZR22 probe junction box. The

check gas and reference air ports require a 1/4” FNPT fitting.

NOTE

Flexible stainless steel hose is recommended for the connection

between the ZR22 and the tubing.

This will allow for probe movement due to thermal expansion of

the duct.

IMPORTANT

To prevent leakage, all compression fittings should be installed

per manufacturer’s recommendations. In addition to this, a

check valve is usually installed on the cal gas inlet of the ZR22

probe to protect the cal tubing from moisture contamination.