4 shutting down the transmitter, 1 draining condensate, Shutting down the transmitter -4 – Yokogawa EJA310E User Manual

Page 37: Draining condensate -4, Important, Warning

<7. Operation>

7-4

IM 01C25B01-01E

IMPORTANT

• Remove the communicator from the terminal

box, and confirm that none of the terminal

screws are loose.

• Close the terminal box cover and the

amplifier cover. Screw each cover in tightly

until it will not turn further.

• There are two covers that must be locked

on the ATEX Flameproof type transmitters.

An Allen head bolt (shrouding bolt) under

the edge of each cover is used to lock the

cover. When the shrouding bolt is driven

counterclockwise with an Allen wrench, the

bolt rotates upward and locks the cover. (See

section 8.4.) After locking the covers, confirm

that they are secure and cannot be opened

by hand.

Tighten the zero-adjustment cover mounting

screw to secure the cover.

• Tighten the zero-adjustment cover mounting

screw to secure the cover.

7.4 Shutting Down the

Transmitter

Shut down the transmitter as follows.

Steps 2) and 3) are specific to the differential

pressure transmitters.

1) Turn off the power.

2) Close the low pressure stop valve.

3) Open the equalizing valve.

4) Close the high pressure stop valve.

5) Close the high pressure and low pressure tap

valves.

NOTE

• Whenever shutting down the transmitter for a

long period, remove any process fluid that is

in the transmitter pressure-detector section.

• The equalizing valve must be left OPEN.

7.5 Venting or Draining

Transmitter Pressure-

detector Section

Since this transmitter is designed to be self-

draining and self-venting with vertical impulse

piping connections, neither draining nor venting

will be required if the impulse piping is configured

appropriately for self-draining or self-venting

operation.

If condensate (or gas) collects in the transmitter

pressure-detector section, the measured pressure

may be in error. If it is not possible to configure the

piping for self-draining (or self-venting) operation,

you will need to loosen the drain (vent) screw on the

transmitter to completely drain (vent) any stagnated

liquid (gas.)

However, since draining condensate or bleeding off

gas disturbs the pressure measurement, this should

not be done when the loop is in operation.

WARNING

Since the accumulated liquid (or gas) may be

toxic or otherwise harmful, take appropriate care

to avoid contact with the body, or inhalation of

vapors.

7.5.1 Draining Condensate

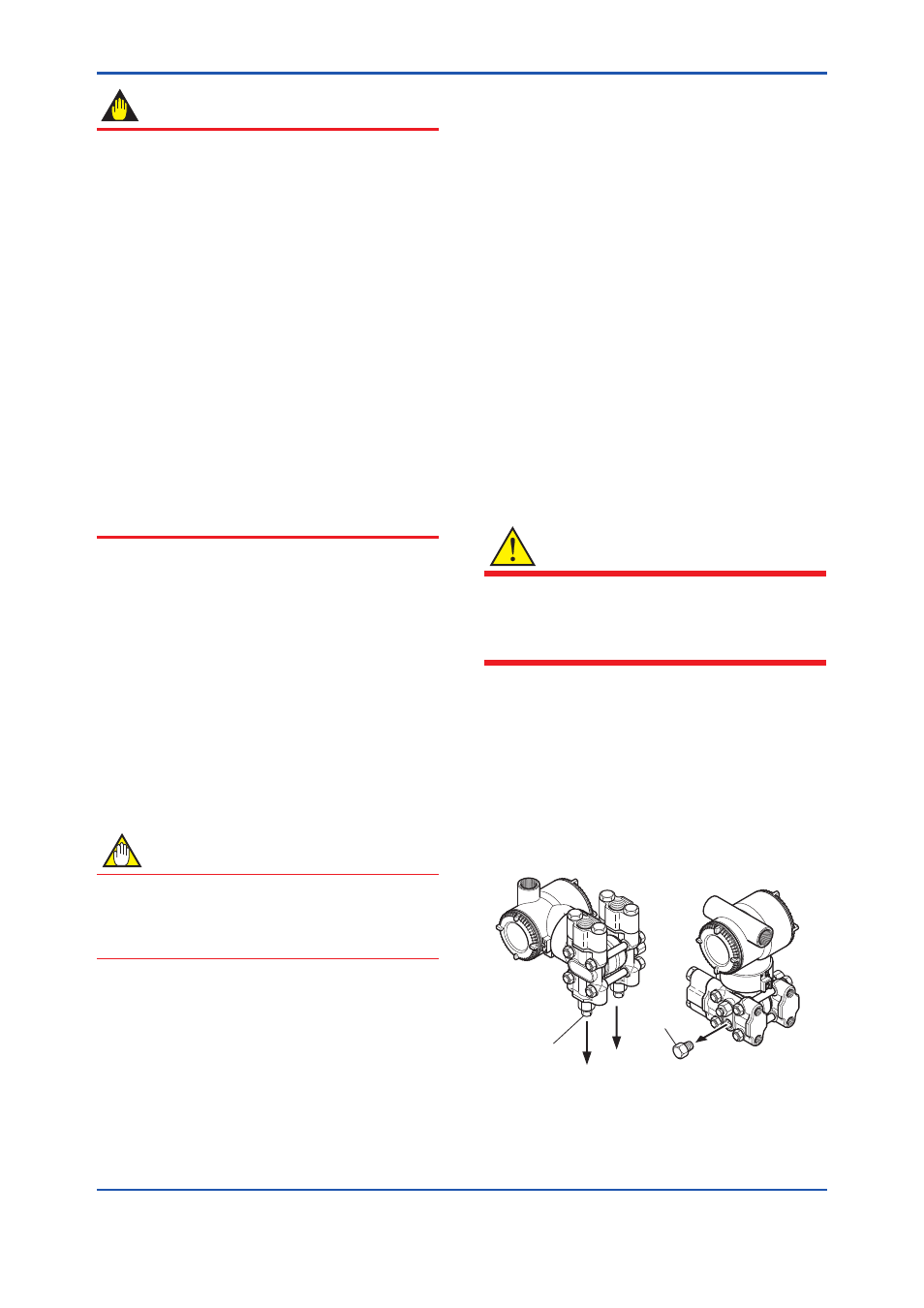

1) Gradually open the drain screw or drain plug

and drain the transmitter pressure-detector

section. (See figure 7.5.)

2) When all accumulated liquid is completely

removed, close the drain screw or drain plug.

3) Tighten the drain screw to a torque of 10 N·m,

and the drain plug to a torque of 34 to 39 N·m.

When you loosen the drain screw or drain

plug, the accumulated liquid will be expelled

in the direction of the arrow.

F0706.ai

Drain screw

Drain plug

Figure 7.5

Draining the Transmitter