3 starting operation, Starting operation -3 – Yokogawa EJA310E User Manual

Page 36

<7. Operation>

7-3

IM 01C25B01-01E

7.2.1 Adjusting Zero Point for Differential

Pressure Transmitters

Before adjusting zero point, make sure that the

equalizing valve is open.

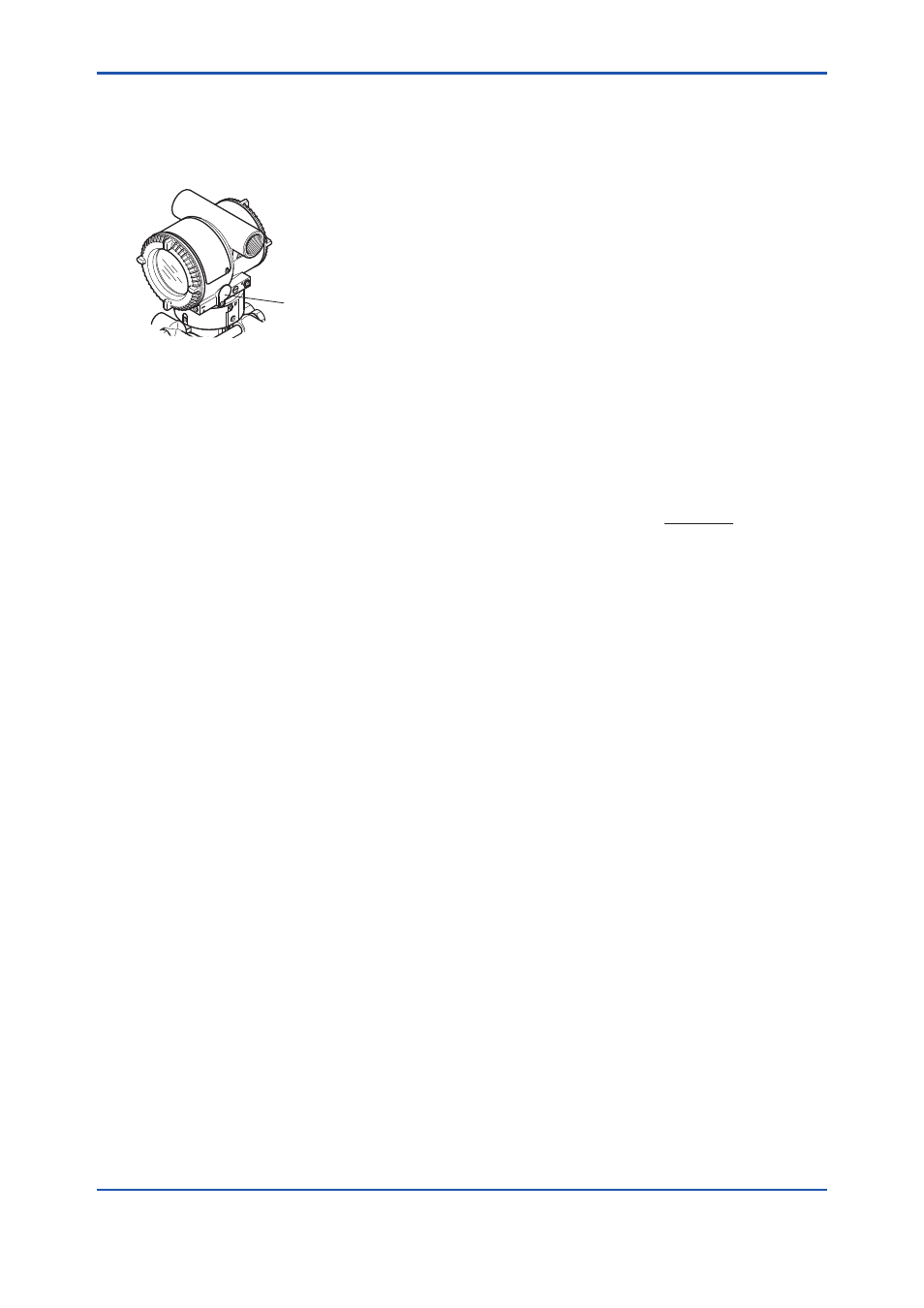

Zero-adjustment

screw cover

F0705.ai

Figure 7.4

External Zero Adjustment Screw

The zero-adjustment screw is located inside the

cover.

Use a slotted screwdriver to turn the zero-

adjustment screw. Equalize the transmitter, then

turn the screw clockwise to increase the output or

counterclockwise to decrease the output. The zero

point adjustment can be made with a resolution

of 0.01% of the setting range. The degree of zero

adjustments varies with the screw turning speed;

turn the screw slowly to make a fine adjustment,

quickly to make a rough adjustment.

When using differential pressure transmitters for

level measurement and if you cannot obtain the

lower range value from the actual measurement

value of 0%, refer to subsection 7.2.2(2).

7.2.2 Adjusting Zero Point for Gauge/

Absolute Pressure Transmitters

(1) When you can obtain the Low Range Value

from the actual measured value of 0% (0

kPa, atmospheric pressure);

For pressure measurement using gauge pressure

transmitters, follow the steps below before

performing zero point adjustment.

1) Close the tap valve (main valve).

2) Loosen the fill plug so that the pressure applied

to the transmitter is only the head of the seal

liquid.

3) Adjust the zero point at this status.

4) After the adjustment, close the fill plug and then

gradually open the tap valve.

Use a slotted screwdriver to turn the zero-

adjustment screw. Turn the screw clockwise

to increase the output or counterclockwise to

decrease the output. The zero point adjustment can

be made with a resolution of 0.01% of the setting

range. Since the degree of the zero adjustment

varies with the screw turning speed, turn the screw

slowly to make a fine adjustment and quickly to

make a rough adjustment.

(2) When you cannot obtain the Low Range

Value from the actual measured value of

0%;

Adjust the transmitter output to the actual measured

value obtained by a digital manometer or a glass

gauge.

[Example]

The measuring range of 50 to 250 kPa; the actual

measured value of 130 kPa.

130–50

250–50

Actual measured value=

x100=40.0%

(=10.4mA)

Turn the screw to match the output signal to the

actual measured value.

7.3 Starting Operation

After completing the zero point adjustment, follow

the procedures below to start operation. Steps

1) and 2) are specific to the differential pressure

transmitters.

1) Close the equalizing valve.

2) Gradually open the low pressure stop valve.

This places the transmitter in an operational

condition.

3) Confirm the operating status. If the output

signal exhibits wide fluctuations (hunting) due to

periodic variation in the process pressure, use

the communicator to dampen the transmitter

output signal. Confirm the hunting using a

receiving instrument or the integral indicator,

and set the optimum damping time constant.

4) After confirming the operating status, perform

the following.