General specifications, 1 standard specifications – Yokogawa EJA118 User Manual

Page 54

IM 1C22H1-01E

9-1

9. GENERAL SPECIFICATIONS

9.

GENERAL SPECIFICATIONS

9.1

Standard Specifications

Refer to GS 1C22T2-E for Fieldbus communica-

tion type marked with “

᭛

”.

᭹

Performance Specifications

See General Specifications sheet, GS 1C22H1-E.

᭹

Functional Specifications

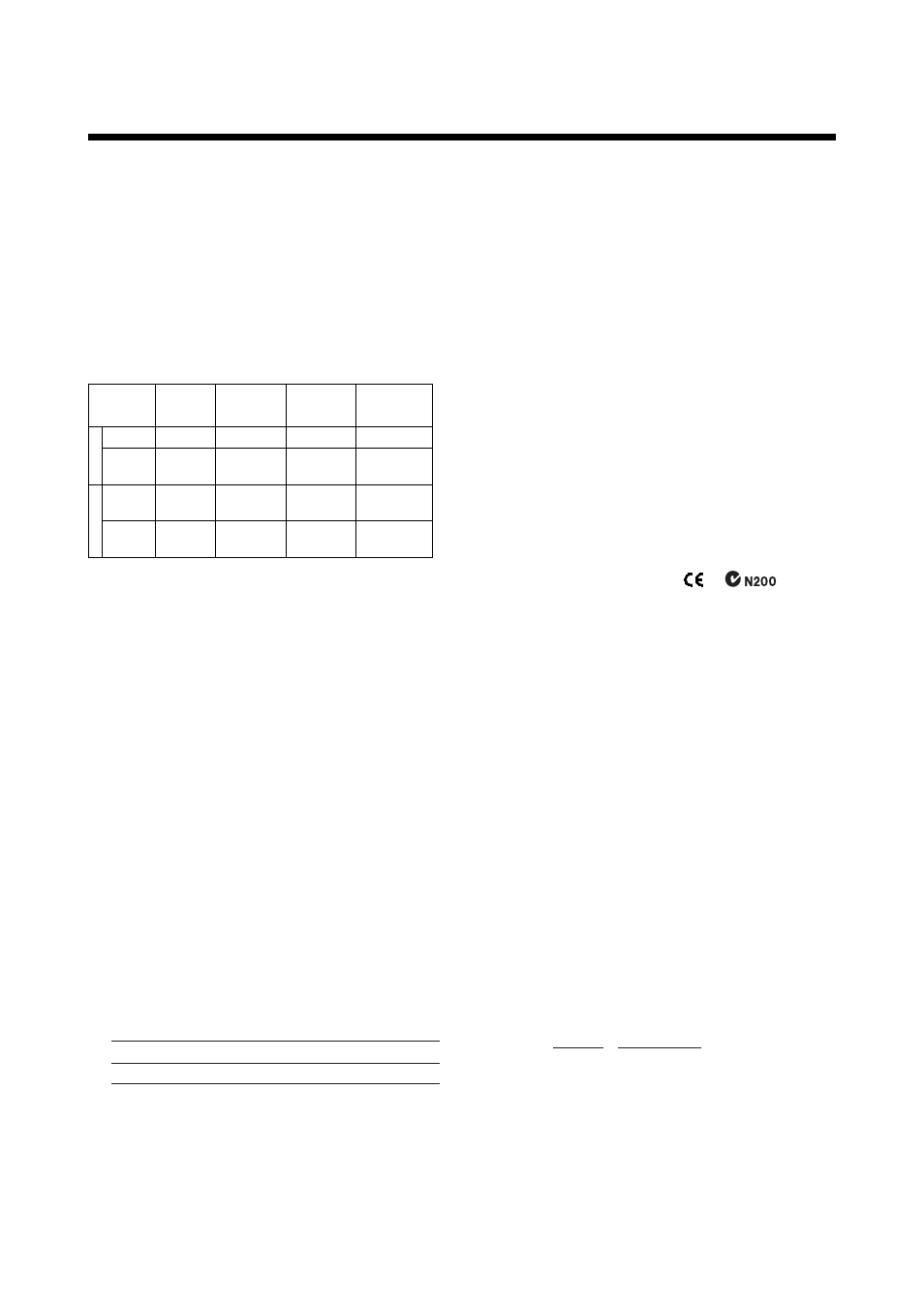

Span & Range Limits

M

Measurement

Span

and Range

Span

Range

inH

2

O

(/D1)

10 to 400

–400 to

400

mbar

(/D3)

mmH

2

O

(/D4)

25 to 1000

–1000 to

1000

250 to 10000

–10000 to

10000

kPa

2.5 to 100

–100 to

100

H

Span

Range

100 to 2000

–2000 to

2000

250 to 5000

–5000 to

5000

0.25 to

5 kgf/cm

2

–5 to

5 kgf/cm

2

25 to 500

–500 to

500

T0901.EPS

URL is define as the Upper Range Limit from the table

above.

Zero Adjustment Limits:

Zero can be fully elevated or suppressed, within

the Lower and Upper Range Limits of the capsule.

External Zero Adjustment “

᭛

”:

External zero is continuously adjustable with

0.01% incremental resolution of span. Span may

be adjusted locally using the digital indicator with

range switch.

Output “

᭛

”:-

Two wire 4 to 20 mA DC output with digital

communications, linear or square root program-

mable. BRAIN or HART FSK protocol are superim-

posed on the 4 to 20 mA signal.

Failure Alarm:

Output status at CPU failure and hardware error;

Up-scale: 110%, 21.6 mA DC or more (standard)

Down-scale: –5%, 3.2 mA DC

Note: Applicable for Output signal code D and E

Damping Time Constant (1st order):

The sum of the amplifier and capsule damping

time constant must be used for the overall time

constant. Amp damping time constant is adjustable

from 0.2 to 64 seconds.

Time Constant (approx. sec)

1.5

1.0

M

H

T0902.EPS

Capsule (Silicone Oil)

When the capillary length 3 m and the fill fluid code

A.

Ambient Temperature Limits:

* Safety approval codes may affect limits.

–40 to 60

°

C (–40 to 140

°

F)

–30 to 60

°

C (–22 to 140

°

F) with LCD Display

Note: The ambient temperature limits must be within

the fill fluid operating temperature range, see

Table 1.

Process Temperature Limits:

* Safety approval codes may affect limits.

See Table 1.

Working Pressure Range:

2.7 kPa {20 mmHg abs} to flange rating pressure.

For atmospheric pressure or below, see Figure 1.

᭹

Installation

Supply & Load Requirements “

᭛

”:

* Safety approvals can affect electrical requirements.

See Section 5.6, ‘Power Supply Voltage and Load

Resistance.’

EMC Conformity Standards:

,

For EMI (Emission): EN55011, AS/NZS 2064 1/2

For EMS (Immunity): EN50082-2

Communication Requirements “

᭛

”:

BRAIN

Communication Distance;

Up to 2 km (1.25 miles) when using CEV polyethyl-

ene-insulated PVC-sheathed cables.

Communication distance varies depending on type

of cable used.

Load Capacitance;

0.22

µ

F or less (see note)

Load Inductance;

3.3 mH or less (see note)

Input Impedance of communicating device;

10 k

Ω

or more at 2.4 kHz.

Note: For general-use and Flameproof type.

For Intrinsically safe type, please refer to

‘Optional Specifications.’

HART

Communication Distance;

Up to 1.5 km (1 mile) when using multiple twisted

pair cables. Communication distance varies

depending on type of cable used.

Use the following formula to determine cable

length for specific applications:

L=

-

65 x 10

6

(R x C)

(C

f

+ 10,000)

C

Where:

L = length in meters or feet

R = resistance in

Ω

(including barrier resistance)

C = cable capacitance in pF/m or pF/ft

C

f

= maximum shunt capacitance of receiving

devices in pF/m or pF/ft