3 transmitter mounting – Yokogawa EJA118 User Manual

Page 20

IM 1C22H1-01E

4-2

4. INSTALLATION

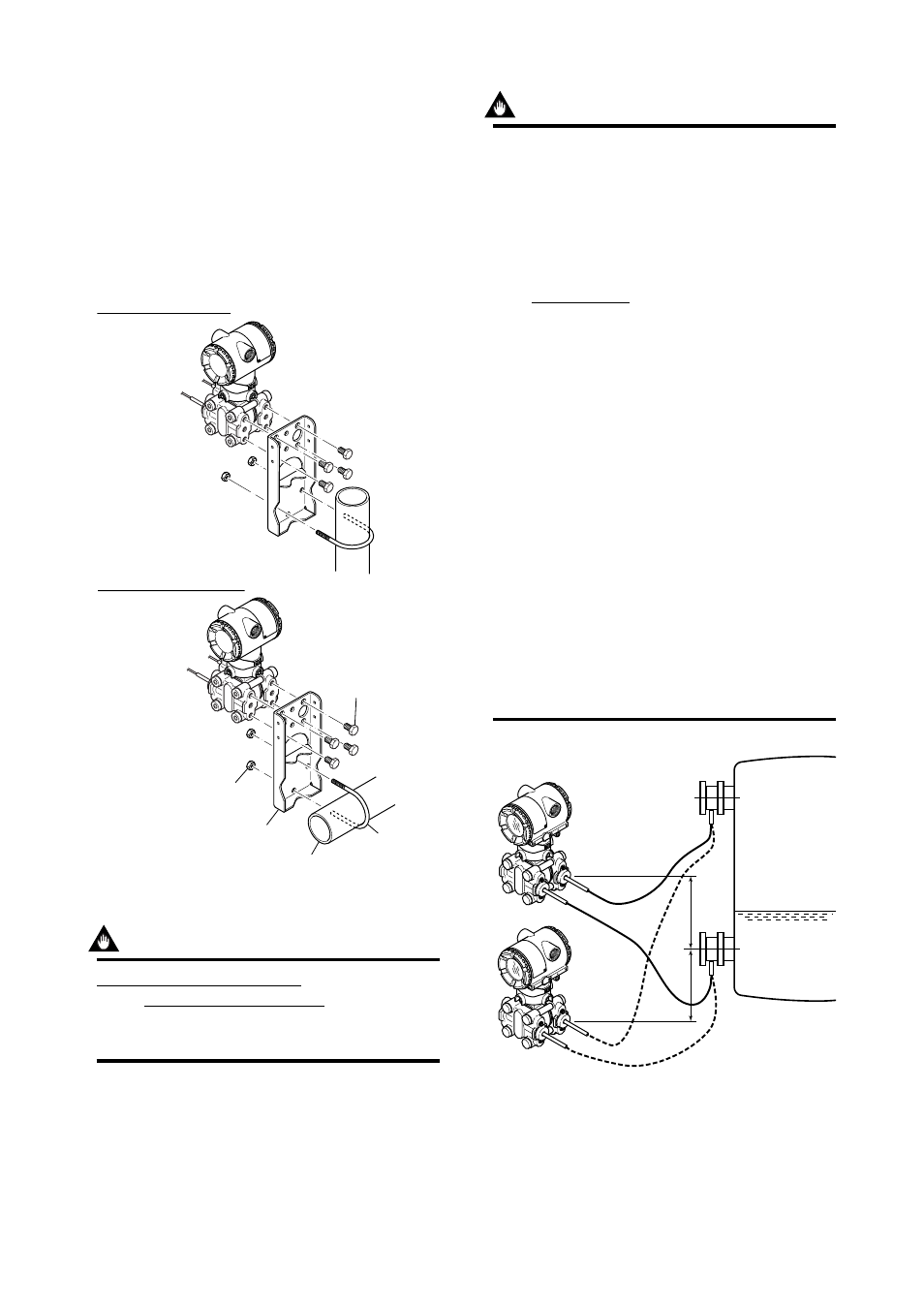

4.3 Transmitter Mounting

The transmitter can be mounted on a nominal 50

mm (2-inch) pipe using the mounting bracket

supplied, as shown in Figure 4.3.1. The transmitter

can be mounted on either a horizontal or a vertical

pipe.

When mounting the bracket on the transmitter,

tighten the (four) bolts that hold the transmitter to a

torque of approximately 39 N·m {4 kgf·m}.

Horizontal pipe mounting

Vertical pipe mounting

Transmitter

mounting bolt

U-bolt nut

Mounting bracket

50mm (2-inch) pipe

U-bolt

F0403.EPS

Figure 4.3.1 Transmitter Mounting

IMPORTANT

Never loosen the four screws securing the cover

flange or the screws at the joints between the

capillary tube and cover flanges (if the seal liquid

leaks, the transmitter cannot be used).

IMPORTANT

The transmitter should be installed at least 600

mm below the high pressure (HP) process

connection to ensure a positive head pressure of

fill fluid. Pay special attention to vacuum applica-

tions. If it can not be installed at least 600 mm

below the HP process connection, please use

the equation below:

h=

ϫ

7.5

ϫ

10

–3

[mm]

(P–P0)

ϫ

dHg

ds

h:

Vertical height between the HP process

connection and the transmitter (mm)

h

≤

0: Install the transmitter at least h (mm)

below the HP process connection

h>0: Install the transmitter at most h (mm)

above the HP process connection

P:

Pressure in the tank (Pa abs)

P0: Minimum working pressure limit of the

transmitter (Pa abs)

If the ambient temperature range is

–10 to 50

°

C.

3178 (Wetted parts material code S)

3596 (Wetted parts material code T)

6074 (Wetted parts material code H)

4711 (Wetted parts material code U)

ds: Specific gravity of fill fluid (at 25

°

C), refer

to GS 1C22H1-E.

dHg:Specific gravity of the Mercury 13.6

(at 25

°

C)

F0404.EPS

P

h

Low pressure side

0

High

pressure

side

(+)

(–)

Figure 4.3.2 Example of Installation to Tank (Caution on

Installation)