Yokogawa EJA220A User Manual

Page 64

IM 01C21C01-01E

10-7

10. GENERAL SPECIFICATIONS

( Test Pressure )

2MPa {20 kgf/cm

2

}

5MPa {50 kgf/cm

2

}

3MPa {29.8 kgf/cm

2

}

7.7MPa {77 kgf/cm

2

}

7MPa {70 kgf/cm

2

}

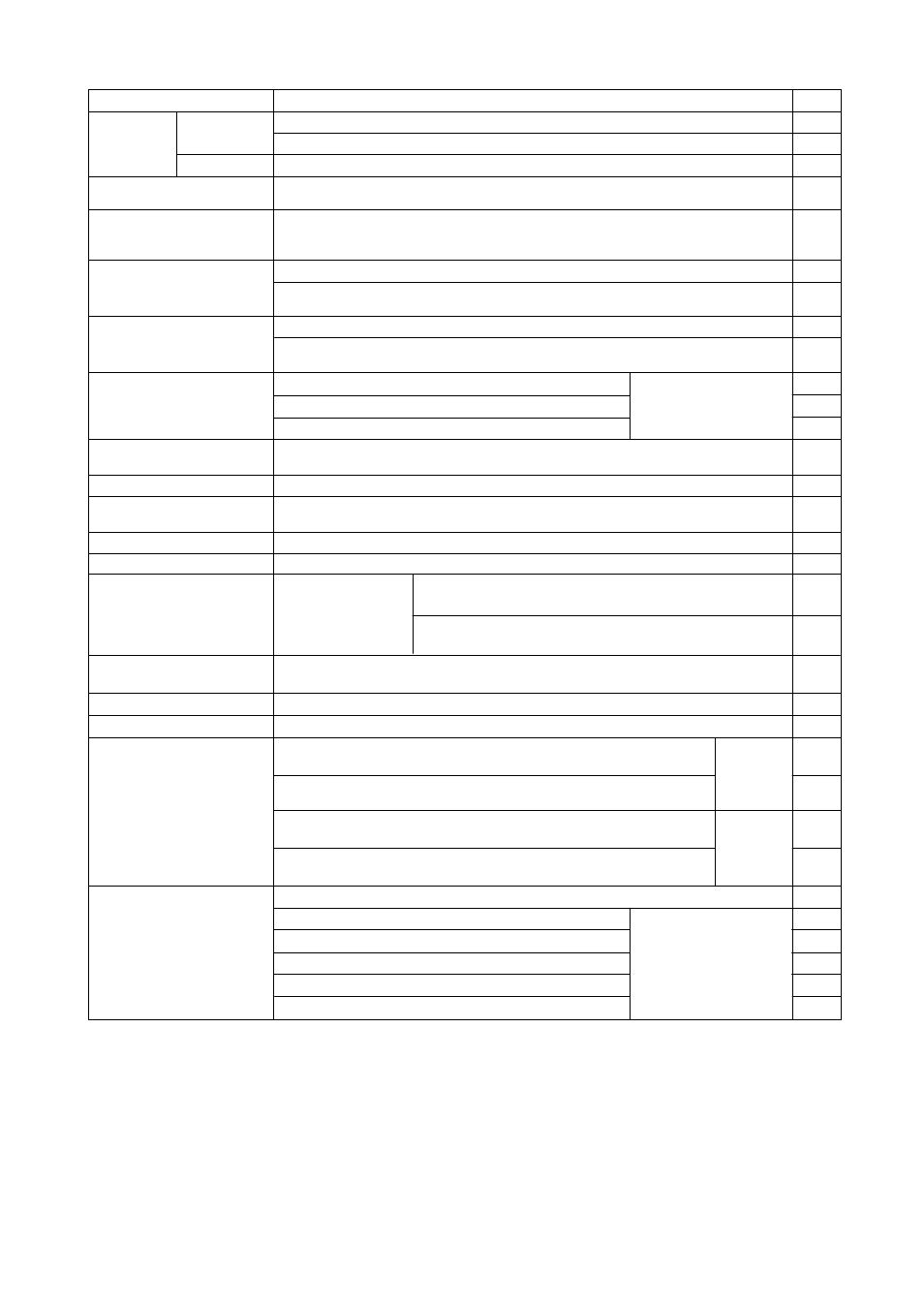

Item

Description

Code

Painting

Color change

Coating change

Lightning protector

Calibration units

Sealing treatment to

SUS630 nuts

No serration

Teflon film

Fast response *

2

P

ᮀ

PR

X1

A

K1

D1

D3

D4

Y

Q

T

F1

( See Table for Span

and Range Limits. )

Amplifier cover only

Amplifier cover and terminal cover, Munsell 7.5 R4/14

Epoxy resin-baked coating

Transmitter power supply voltage: 10.5 to 32 V DC (10.5 to 30 V DC for intrinsically safe

type, 9 to 32 V DC for F

OUNDATION

Fieldbus and PROFIBUS PA communication type.)

Allowable current: Max. 6000 A (1

؋40 µs ), Repeating 1000 A,100 times

Degrease cleansing treatment

P calibration (psi unit )

bar calibration (bar unit )

M calibration ( kgf/cm

2

unit )

Sealant ( liquid silicone rubber )

316 SST exterior parts

HC

Exterior parts on the amplifier housing (name plates, tag plate, zero-adjustment screw,

stopper screw) will become 316 or 316L SST.

No serration work on the flange gasket surface ( for ANSI flange only )

With FEP film and fluorinated oil. Working range: 20 to 120 °C, 0 to 2 MPa {0 to 20 kgf/cm

2

}

(Not usable under vacuum )

K2

Degrease cleansing treatment with fluorinated oil filled capsule.

Operating temperature –20 to 80 °C

Oil-prohibited use

Mill Certificate

High pressure side: Process flange, Block

Low pressure side: Cover flange

M03

Pressure test/

Leak test

Certificate

High pressure side: Process flange, Block

Low pressure side: Cover flange, Process connector

High pressure side: Process flange, Block, Pipe, Base

Low pressure side: Cover flange

High pressure side: Process flange, Block, Pipe, Base

Low pressure side: Cover flange, Process connector

M13

M04

M14

( Flange rating )

JIS 10K

JIS 20K

ANSI/JPI class 150

ANSI/JPI class 300

ANSI/JPI class 300

T31

T32

T36

T37

T38

Nitrogen ( N

2

) Gas

Retention time: 10 minutes

For

model

EJA210A

For

model

EJA220A

K5

Degrease cleansing and dehydrating treatment

K6

Degrease cleansing and dehydrating treatment with fluorinated oil filled capsule.

Operating temperature –20 to 80 °C

Oil-prohibited use

with dehydrating treatment

Stainless steel amplifier

housing

Amplifier housing material: SCS14A stainless steel

(equivalent to SUS316 cast stainless steel or ASTM CF-8M)

E1

Gold-plate

A1

Gold-plated diaphragm for high pressure side (process flange side)

Stainless steel tag plate

N4

JIS SUS304 stainless steel tag plate wired onto transmitter

Update time: 0.125 sec or less, see GS for response time

T1005.EPS

Failure alarm down-scale *

1

C1

C2

C3

Output status at CPU failure and hardware error is –5%, 3.2 mA or less.

NAMUR NE43 compliant *

1

Output signal limits:

3.8 mA to 20.5 mA

Failure alarm down-scale: output status at CPU failure and

hardware error is –5%, 3.2 mA or less.

Failure alarm up-scale: output status at CPU failure and

hardware error is 110%, 21.6 mA or more.

* 1:

Applicable for Output signal code D and E. The hardware error indicates faulty amplifier or

capsule. When combining with Optional code F1, output status for down-scale is –2.5%,

3.6 mA DC or less.

* 2:

Applicable for Output signal code D and E. Write protection switch is attached for Output code E.