Model eja220a – Yokogawa EJA220A User Manual

Page 61

IM 01C21C01-01E

10-4

10. GENERAL SPECIFICATIONS

᭹ Model EJA220A

. . . . . . . . . . . . . . . . . . .

-D . . . . . . . . . . . . . . . . .

-E . . . . . . . . . . . .

(Note 1)

-F . . . . . . . . . . . .

(Note 5)

-G . . . . . . . . . . .

(Note 6)

M . . . . . . . . . . . . . . . .

H . . . . . . . . . . . . . . . .

S . . . . . . . . . .

(Note 3)

W . . . . . . . . .

(Note 4)

J1 . . . . . . . . . . . .

J2 . . . . . . . . . . . . .

A1 . . . . . . . . . . . . .

A2 . . . . . . . . . . . . .

P1 . . . . . . . . . . . . .

P2 . . . . . . . . . . . . .

D2 . . . . . . . . . . . . .

D4 . . . . . . . . . . . . .

2 . . . . . . . . . . . . .

4 . . . . . . . . . . . . .

6 . . . . . . . . . . . . .

G . . . . . . . . . . .

H . . . . . . . . . . .

J . . . . . . . . . . .

D . . . . . . . . . . .

E . . . . . . . . . . .

F . . . . . . . . . . .

0 . . . . . . . . . .

1 . . . . . . . . . .

2 . . . . . . . . . .

3 . . . . . . . . . .

4 . . . . . . . . . .

5 . . . . . . . . . .

A . . . . . . . . .

B . . . . . . . . .

C . . . . . . . . .

-9 . . . . . . .

0 . . . . . .

2 . . . . . .

3 . . . . . .

4 . . . . . .

5 . . . . . .

7 . . . . . .

8 . . . . . .

9 . . . . . .

A . . . . . .

C . . . . . .

D . . . . . .

D . . . . .

E . . . . .

N . . . . .

N . . . .

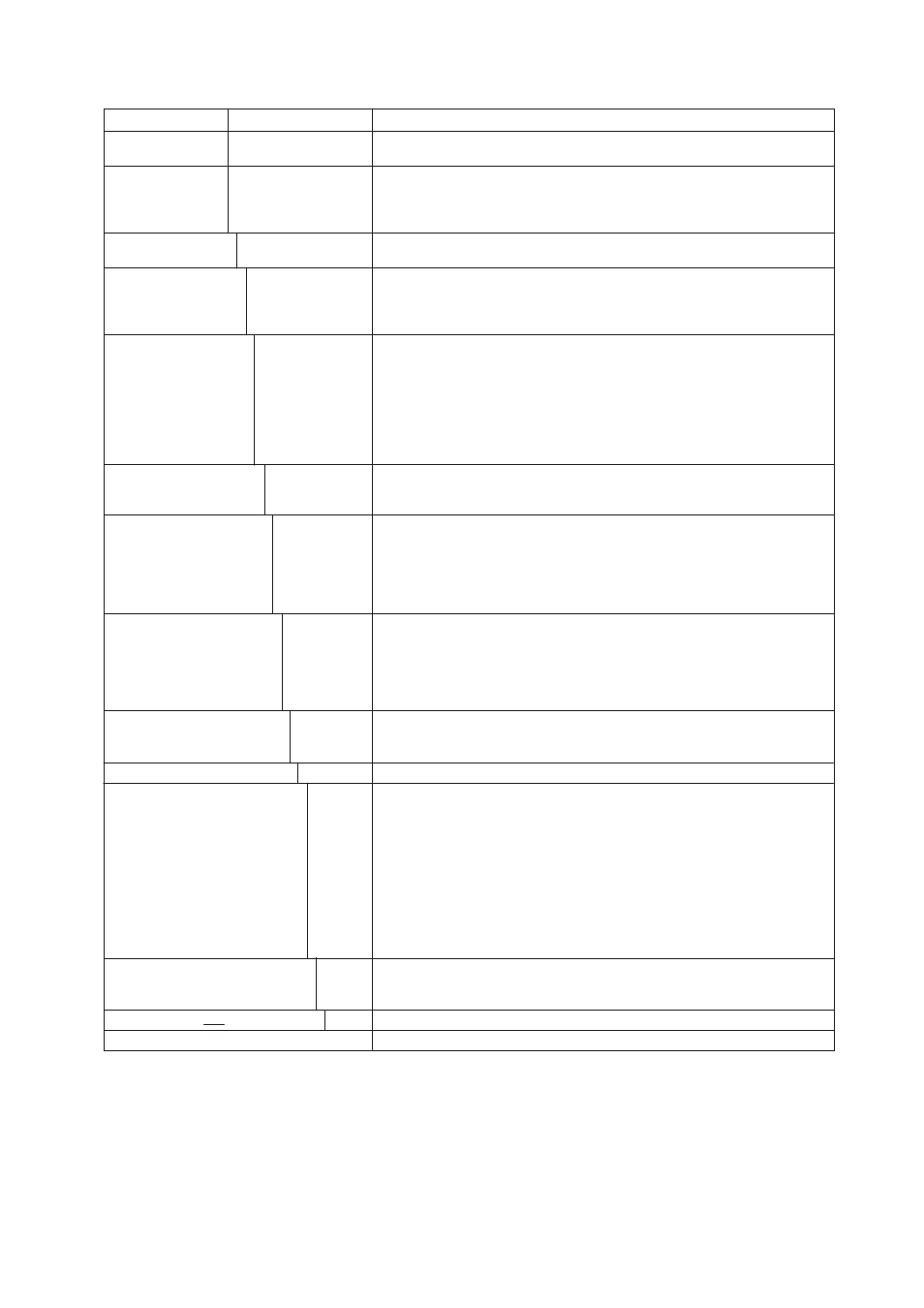

Model

Suffix Codes

Description

EJA220A

Output Signal

Measurement span

(capsule)

High pressure side

(Process flange side)

wetted parts material

(Note 2)

Process flange rating

Diaphragm extension

length (X

2

)

Process flange

size/material

Low pressure side process

connection

Bolts and nuts material

Installation

Electrical connection

Integral indicator

Optional codes

Flange-mounted differential pressure transmitter

(Extended diaphragm type)

4 to 20 mA DC with digital communication (BRAIN protocol)

4 to 20 mA DC with digital communication (HART protocol)

Digital communication (F

OUNDATION

Fieldbus protocol)

Digital communication (PROFIBUS PA protocol)

1 to 100 kPa {100 to 10000 mmH

2

O}

5 to 500 kPa {0.05 to 5 kgf/cm

2

}

[Diaphragm] [Pipe] [Others]

SUS316L SUS316

SUS316

Hastelloy C-276

SUS316

SUS316

JIS10K

JIS20K

ANSI Class 150

ANSI Class 300

JPI Class 150

JPI Class 300

DIN PN10/16

DIN PN25/40

X

2

=50 mm

X

2

=100 mm

X

2

=150 mm

4-inch (100 mm) / S25C

4-inch (100 mm) / SUS304

4-inch (100 mm) / SUS316

3-inch (80 mm) / S25C

3-inch (80 mm) / SUS304

3-inch (80 mm) / SUS316

without process connector (Rc1/4 female on the cover flanges)

with Rc1/4 female process connector

with Rc1/2 female process connector

with 1/4 NPT female process connector

with 1/2 NPT female process connector

without process connector (1/4 NPT female on the cover flanges)

SCM435

SUS630

SUH660

Horizontal impulse piping type, left side high pressure

G1/2 female, one electrical connection

1/2 NPT female, two electrical connections without blind plug

Pg 13.5 female, two electrical connections without blind plug

M20 female, two electrical connections without blind plug

G1/2 female, two electrical connections and a blind plug

1/2 NPT female, two electrical connections and a blind plug

Pg 13.5 female, two electrical connections and a blind plug

M20 female, two electrical connections and a blind plug

G1/2 female, two electrical connections and a SUS316 blind plug

1/2 NPT female, two electrical connections and a SUS316 blind plug

M20 female, two electrical connections and a SUS316 blind plug

Digital indicator

Digital indicator with the range setting switch

(None)

Always N

/

ᮀ Optional specification

T1003.EPS

Example: EJA220A-DMSA12G5A-92NN/

ᮀ

Note 1: Refer to IM 01C22T01-01E for HART Protocol version.

Note 2: Low pressure side wetted parts material: Cover flange; SCS14A, Process connector; SCS14A,

Capsule; SUS316L (Diaphragm, Hastelloy C-276), Vent plug ; SUS316

Note 3: Applicable only for 4-inch (100 mm) flange size (Process flange size/material codes G and H).

Note 4: Applicable only for 3-inch (80 mm) flange size (Process flange size/material codes D and E).

Note 5: Refer to IM 01C22T02-01E for Fieldbus communication.

Note 6: Refer to IM 01C22T03-00E for PROFIBUS PA communication.