Operating instructions, Tests, Maintenance, testing – Ross Controls CATEGORY 4 - 5_2 VALVES CROSSMIRROR SERIES 77 User Manual

Page 10: Repair, 5/2-way double valves with c, Sensing

10

www.rosseuropa.com

OPERATING INSTRUCTIONS

Pressure failure test

The valve is in the at-rest position. Turn off operating

pressure at port 1 and exhaust the operating

pressure line. Actuate the valve in the normal way

(solenoids A and B in t < 0,5s), and keep the

solenoids energized. Then apply operating pressure

to port 1 again. The piston is not supposed to leave

its position. For checking the check valve in port 1,

close and exhaust the operating pressure line. If

the check valves close properly, the piston will not

move downward quickly. Depending on the intensity

of usage, the check valves should be checked at

three month’ intervals.

Malfunctions

In case of malfunctions, we recommend to check/

exchange the double valve immediately.

Maintenance, testing

Maintenance and testing procedures must follow

the rules and guidelines set by the respective nati-

onal work-safety institutions. These procedures

should only be performed by persons trained and

experienced in the use of pneumatic equipment. It

is recommended that maintenance and test

procedures be performed at least once a year,

unless otherwise specified.

Repair

It is recommended that double valves which need

to be serviced be handed over to a ROSS service

point. Customers maintaining their own repair

service have to make sure that only original spare

parts (as specified in the ROSS parts lists) be used.

Pneumatic equipment should be repaired only by

persons trained and experienced in the repairing of

such equipment, guided by these operating

instructions. Information about valve repair and/or

the exchange of a valve must be written down in

the machine operation documentation.

Start-up

Prior to start-up, the installation must be checked thoroughly by persons trained and experienced in the

operation of pneumatic equipment.

Make sure that the maximum operating pressure specified on the valve

label will not be exceeded. When operating pressure is applied, the cylinder piston must move into the at-

rest-position. For further testing, a

functional test

as well as a

pressure failure test

must be performed.

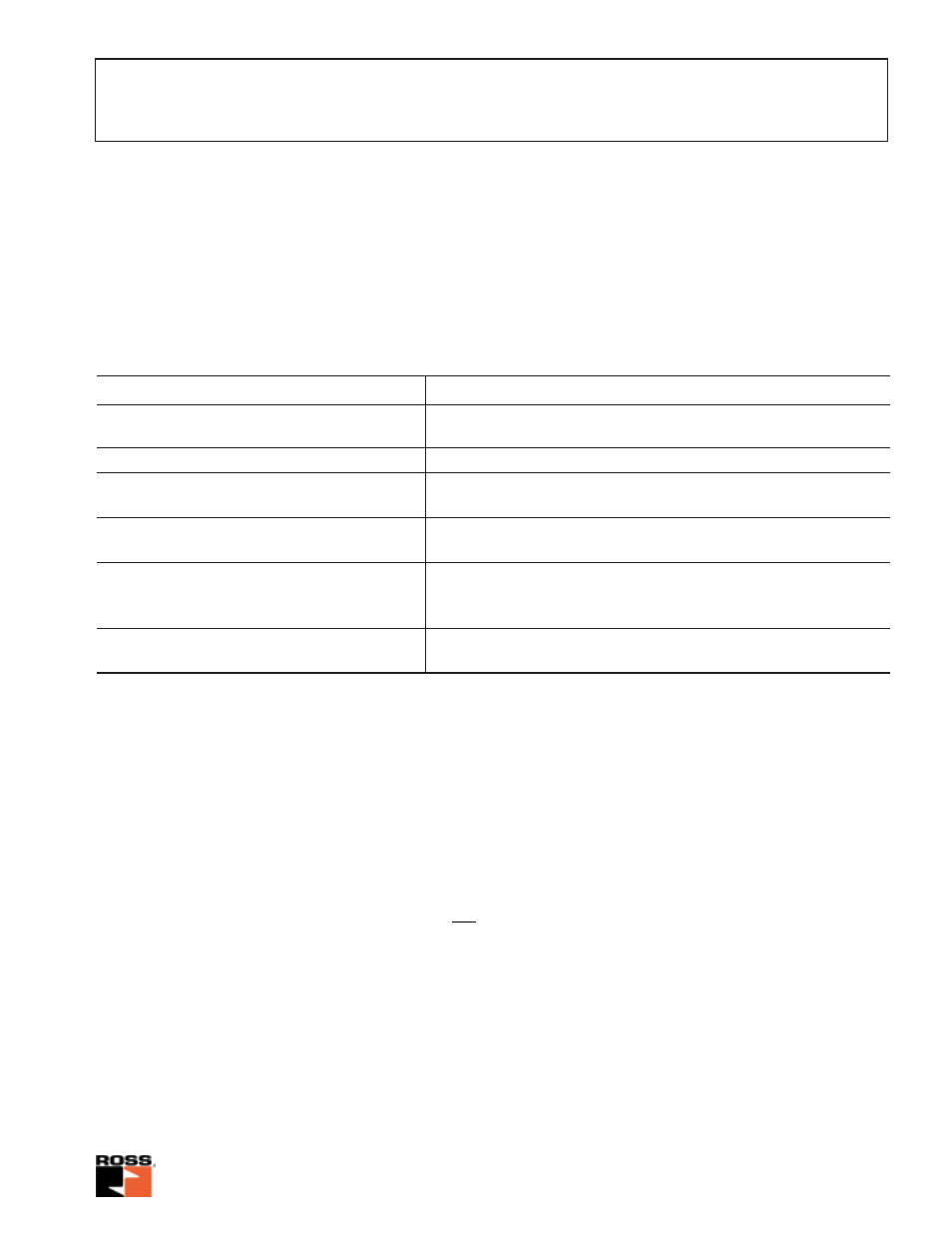

Functional test

Test

Result

1. Actuate solenoid A

Piston does not move

2. Actuate solenoid B

Piston does not move

3. Actuate solenoid A, then actuate

solenoid B after t > 0,5s

Piston does not move

4. Actuate solenoid B, then actuate

solenoid A after t > 0,5s

Piston does not move

5. Actuate solenoids A and B after t < 0,5s

then de-energize solenoid A and

Piston moves, but returns to at-rest-position after solenoid A

re-actuate after t > 0,5s

is de-energized, and remains in that position

6. As under 5., however, test to be

performed with solenoid B

See result 5

5/2-Way Double Valves

with C

ROSS

M

IRROR

®

-Sensing