Reelcraft Series 40 Hose Reels User Manual

Page 2

Series 40 Hose Reels

Page 2

www.reelcraft.com

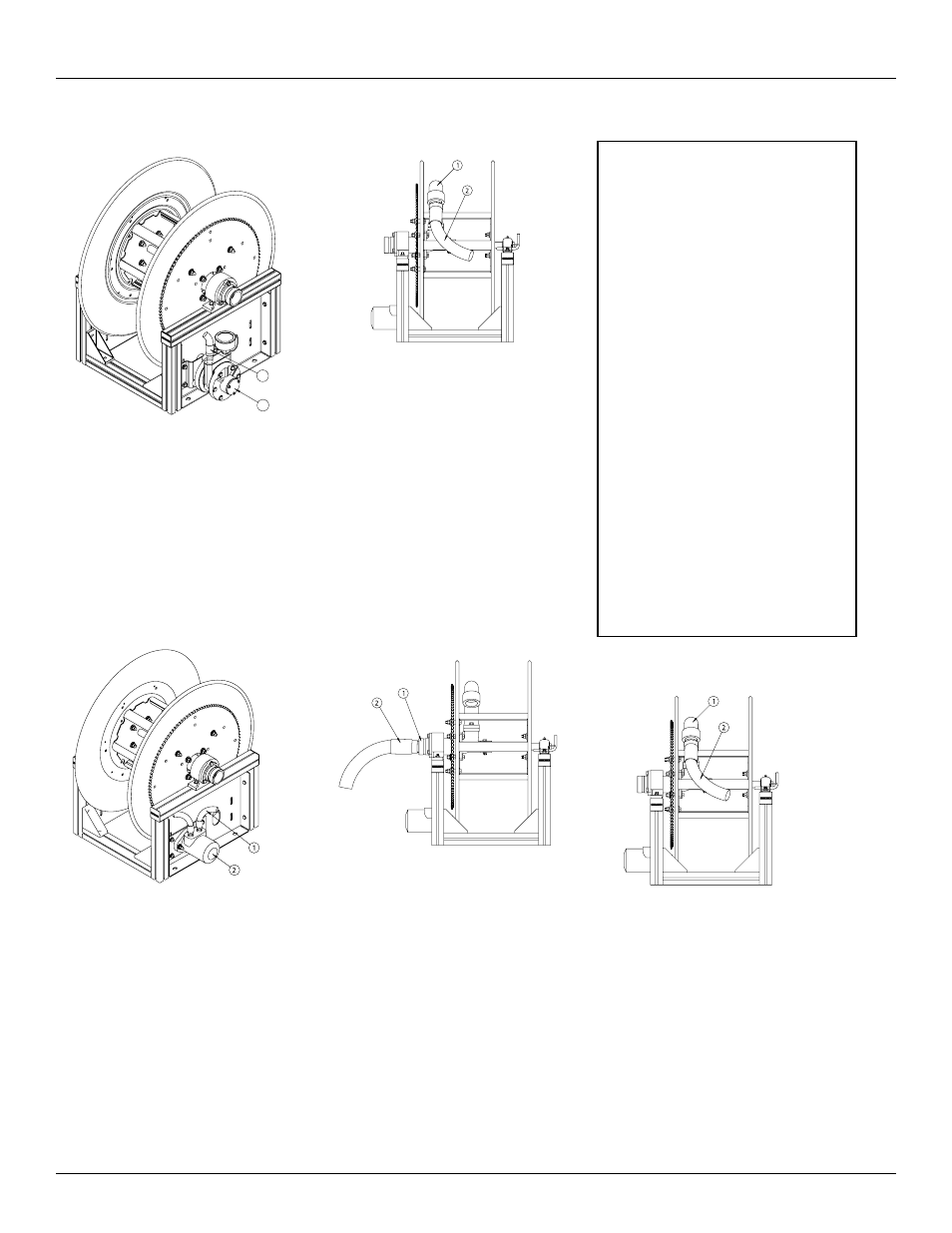

Air Driven Reels

WARNING: Do not exceed 100 PSI

motor inlet pressure. Use an FRL or

control valve (in line) to adjust speed of

motor.

1. If location of motor does not satisfy

mounting/operating requirements refer

to “Modifications” in this manual.

2. Connect inlet air line (1) to motor (2).

Hydraulic Driven Reels

1. If location of motor does not satisfy

mounting/operating requirements refer

to “Modifications” in this manual.

2. Apply thread compound to inlet/outlet

hydraulic line fittings (1) and motor

inlet threads (2).

3. Thread hydraulic line fittings (1) into

motor inlet/outlet (2). Tighten securely.

Connecting the Output Hose

CAUTION: Do not connect the output

hose to the connecting tube assembly

until after reel is installed and motor

connections are complete.

1. Apply thread compound to connecting

tube assembly (1) and output hose

fitting threads (2).

2. Hand thread output hose fitting (2)

into connecting tube assembly (1).

3. Using a wrench, firmly hold

connecting tube assembly (1) while

tightening output hose fitting (2).

Connecting the Supply Line

NOTE: A flexible coupling must be used

to compensate for any offset between the

supply line and reel swivel.

1. Apply thread compound to swivel (1)

and connecting hose fitting (2) threads.

2. Thread connecting hose fitting (2) into

swivel (1). Tighten securely.

3. With control valve open, fully extend

and charge hose to purge system of

gases. When fluid appears at control

valve, close valve. This prevents

flattening of hose and excessive

pressure on drum when fluid supply is

reinitialized at a later time.

Operating Instructions

Service Instructions

Replacing the Output Hose

1. Using a wrench, firmly hold the

connecting tube assembly (1) while

removing the connecting hose fitting

(2).

2. To install new hose, see “Connecting

Output Hose” in Installation

Instructions.

2

1

WARNING- PREVENT STATIC

SPARKING

When working around flammable

liquids such as solvents, paints,

chemicals, or petroleum products,

ensure that the hose reel, hose, and

equipment being serviced is properly

grounded. Use a grounded hose (static

wire). Use an ohmmeter to check

continuity of the ground circuit. Fire

and/or explosion can result if proper

grounding is not achieved.

CAUTION: If reel is electric, air, or

hydraulic driven be careful of chain/

sprocket and/or gear drive system. Keep

hands clear and do not wear loose fit-

ting clothing while operating reel. If reel

ceases to unwind or rewinds, remove

power immediately. Do not pull or jerk

on hose. Find and remedy problem

before continuing. Pull hose by grasp-

ing hose itself, not the control valve or

swivel.