Reelcraft Series 40 Hose Reels User Manual

Operating instructions, Series 40 hose reels, Important

IMPORTANT

Read this manual carefully before installing,

operating or servicing this equipment.

Operating Instructions

Series 40 Hose Reels

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • [email protected] • www.reelcraft.com

Form# 261787 Rev: 6/2013

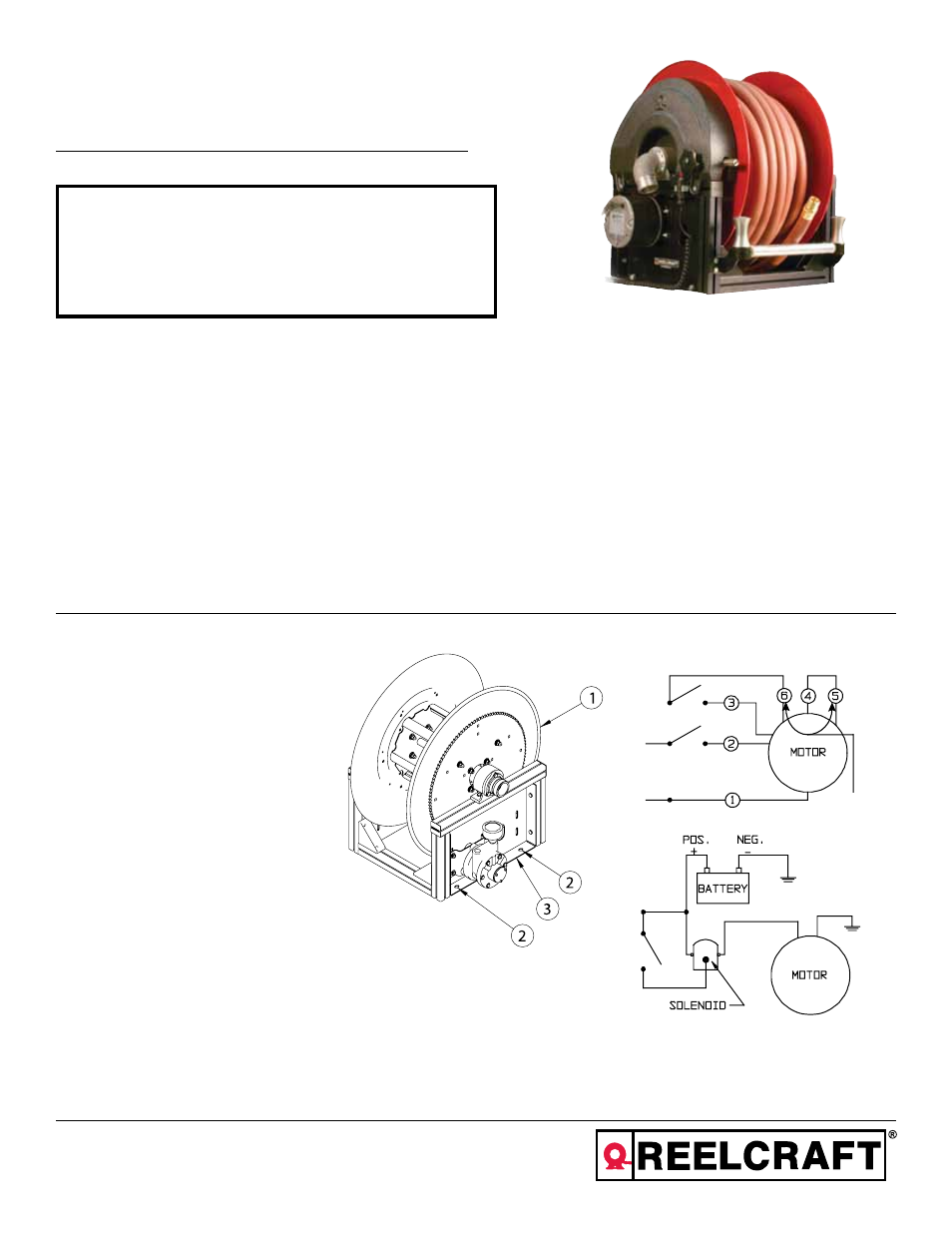

Series 40 with gear drive

Safety Precautions

Personal injury and /or equipment damage

may result if proper safety precautions are

no observed.

• Ensure that reel is properly installed

before connecting supply line (see

installation instructions).

•

• Before connecting supply line to reel,

ensure that supply line pressure does

not exceed maximum rated working

pressure of reel.

• Even low pressure is very dangerous

and cause irreparable damage or death.

•

• Do not wear loose fitting clothing while

operating reel.

•

• Be aware of other personnel and

machinery in work area.

•

• If a leak occurs in the hose or reel,

remove supply line pressure immedi-

ately.

•

•

•

• If reel is electric driven, check for

loose, frayed and broken wires before

operating.

•

• Treat and respect a hose reel as any

other piece of machinery, observing all

common safety practices.

•

• Even low voltage can cause irreparable

damage or death! Exercise extreme

caution while operating or servicing

this equipment.

Installation Instructions

Mounting

1. Unpack and inspect reel for damage.

Rotate sheave (1) to check for

smooth operation. Check for

completeness.

2. Ensure that mounting surface is flat

to prevent binding of reel after it is

installed.

3. Secure reel to mounting surface by

inserting four screws or bolts

(customer supplied) through the

four mounting holes (2) located in

reel base (3). Tighten securely to

ensure a solid, rigid attachment.

Manual Driven Reels

Additonal mounting instructions are not

required.

Hot

Neutral

SINGLE POLE SINGLE-THROW

DOUBLE POLE SINGLE-THROW SWITCH

Connection shown

gives counterclock-

wise rotation look-

ing at end of motor

shaft. To reverse

rotation interchange

Leads 5, 6.

12/24 VOLT D.C.

110 Volt A.C.