Ramsey Winch RPH-20000 (RAMSEY GBX) User Manual

Page 12

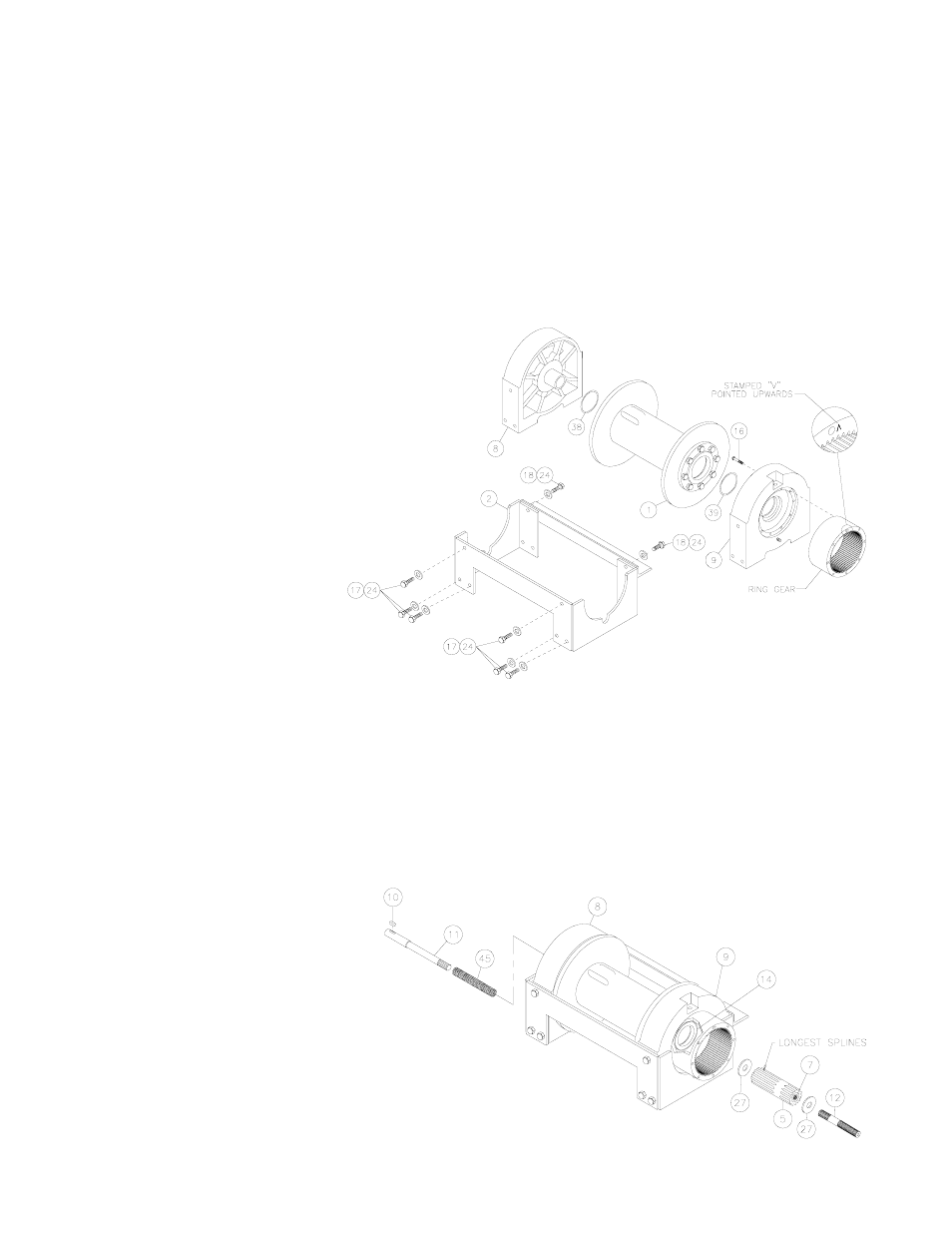

8. NOTE: DETERMINE MOUNTING CONFIGURATION OF WINCH (R.H. or L.H. MOUNTED)

BEFORE ATTACHING UPRIGHT FRAME TO WINCH, TO ASSURE PARTS ARE MOUNTED TO

PROPER SIDE, REFER TO WINCH MOUNTING CONFIGURATIONS, STEP 14 PAGE 12.

Seat well-oiled quad-rings (item #38 & #39) into groove of bushing in each end of drum assembly

(item #1), as shown. Carefully set drum assembly (item #1) down over motor end bearing (item

#8). Apply RTV sealing compound to ring gear mounting surface of gear housing end bearing

(item #9). Place end of ring gear (component of item #3) with 10 tapped holes onto end bearing,

aligning holes in ring gear with holes in gear housing end bearing (be sure that stamped "V"

points upward as shown). Attach ring gear to end bearing (item #9) using (10) capscrews (item

#16). Torque capscrews to 44 ft. lbs. each, in a criss cross pattern. Lift gear housing end bearing

(item #9) and set into place

on drum assembly. Attach

upright frame (item #2) to

end bearings. Install (4)

upper-most capscrews

(items #17 & #18) with lock-

washers (item #24) and

hand tighten. Install (8)

lower-most capscrews with

lockwashers (item #17 &

#24). Tighten (4) upper-most

capscrews securely, check

rotation of cable drum.

Tighten (8) lower-most cap-

screws securely, check rota-

tion of cable drum. Torque

capscrews, in above upper-

most then lower-most pat-

tern, to 85 ft. lbs. each.

Make sure cable drum

assembly rotates freely at this point.

9. Gently tap key (item #10) into keyway of input shaft (item #11). Liberally apply grease to shoulder

of input shaft (item #11). Place spring (item #45) over splined end of shaft. Use grease to hold

spring in place on shaft.

Place spring and splined end of shaft through motor end bearing (item #8) and drum until shaft

extends through bushing (item #14). Place clutch washer (item #27) over splined end of shaft

and against spring. Place end of

output coupling assembly (item

#5), with longest splines, through

end bearing bushing (item #14)

and mesh shaft coupling (item

#7) spline with splined end of

shaft. Place short splined end of

shifter shaft (item #12) through

washer (item #27) and into shaft

coupling (item #7), meshing

splines of shifter shaft with

splines in shaft coupling.

9