Pre-operation installation, Warning caution – Lincoln Electric IM10155 SAE-300 HE User Manual

Page 10

A-3

INSTALLATION

SAE-300

®

HE

Welder Enclosure - The complete welder is rubber mounted on

a rugged steel “C” channel base.

The output terminals are placed at the side of the machines so

that they are protected by the door. The output terminals are

labeled (+) and (-).

Cranking System - A 12 volt electric starter is standard.

Air Cleaner - Heavy duty two stage dry type.

Muffler - A muffler and stainless steel exhaust outlet elbow are

standard.

Fuel / Hour / LED gauge - A meter to record hours of operation,

show fuel status, battery charging fault LED and engine fault

LED.

Engine Protection - The system shuts the engine down in the

event of sudden low oil pressure or high coolant temperature. A

warning light on the control panel will indicate such a fault. To

reset the engine for restarting, turn the ignition switch off then

on. Refer to Troubleshooting section for all warning light fault

codes.

Battery Charging Light - A warning indicator light for Low/No

battery charge. The light is off when the systems are functioning

properly. The light will come on if there is a Low/No battery

condition but the machine will continue to run.

NOTE: The light will come on when the Run/Stop switch is in the

“ON” position. It will come on during cranking and stay on until

the engine starts. After, starting the engine the light will go off

unless a Low/No battery condition exists.

Oil Drain Valve - A ball valve, hose and clamp are standard.

Remote Control - The Remote / Local Switch and Receptacle

are standard.

PRE-OPERATION INSTALLATION

EXHAUST SPARK ARRESTER

Some federal, state or local laws may require that engines be

equipped with exhaust spark arresters when they are operated in

certain locations where unarrested sparks may present a fire

hazard. The standard muffler included with this welder does not

qualify as a spark arrester. When required by local regulations, a

suitable spark arrester must be installed and properly main-

tained.

Use of an incorrect arrester may lead to engine damage or

performance loss. Contact the engine manufacturer for

specific recommendations.

LOCATION / VENTILATION

Always operate the welder with the doors closed. Leaving the doors

open changes the designed air flow and may cause overheating.

The welder should be located to provide an unrestricted flow of

clean, cool air. Also, locate the welder so that engine exhaust

fumes are properly vented to an outside area.

Do not attempt to use this equipment until you have thoroughly

read the engine manufacturer’s manual supplied with your

welder. It includes important safety precautions, detailed

engine starting, operating and maintenance instructions, and

parts lists.

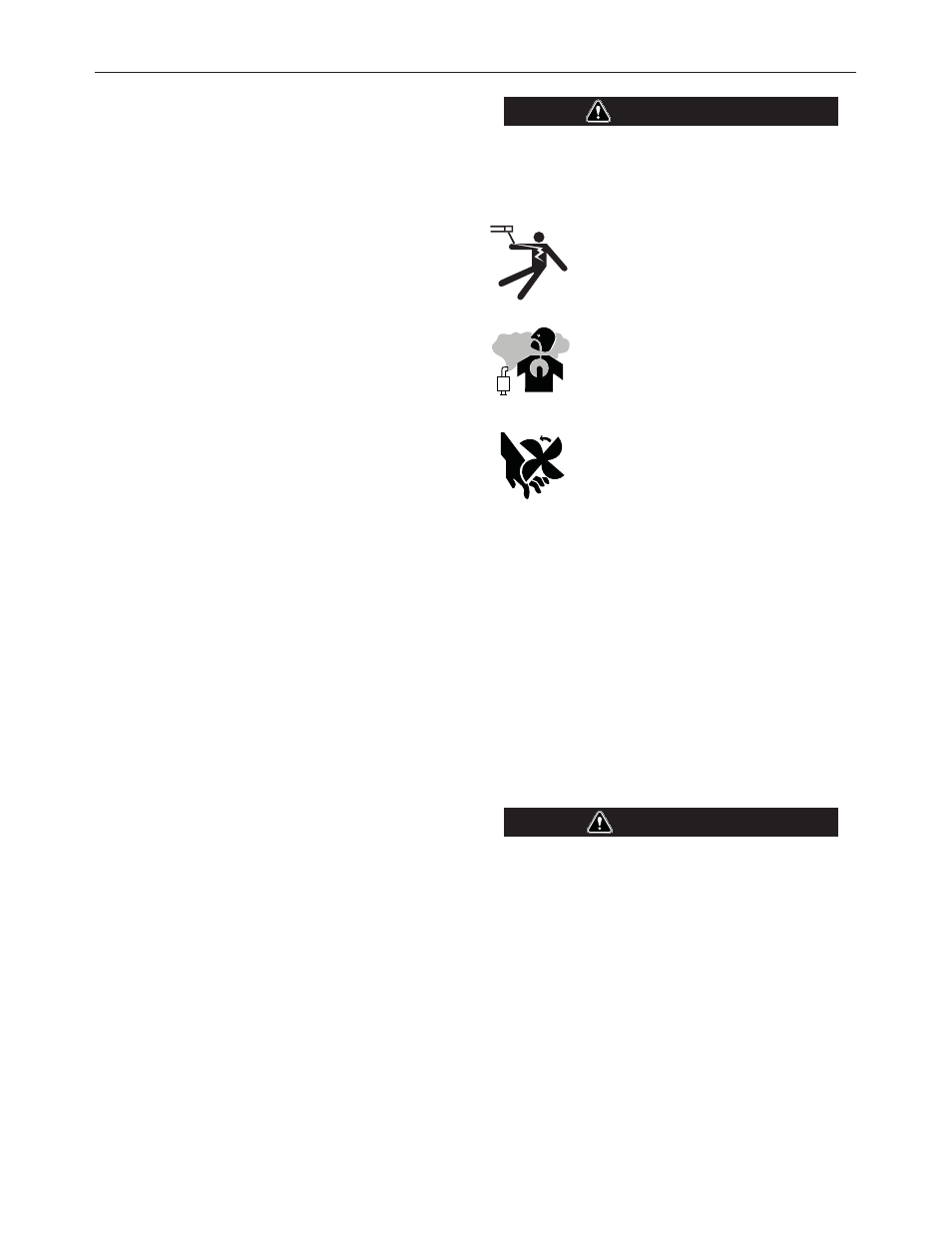

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or elec-

trode with skin or wet clothing.

• Insulate yourself from work and ground

• Always wear dry insulating gloves.

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas or vent

exhaust outside.

MOVING PARTS can injure.

• Do not operate with doors open or guards

off.

• Stop engine before servicing.

• Keep away from moving parts.

See additional warning information at the front of

this operator’s manual.

WARNING

CAUTION