Operation, Engine operation, Stopping the engine – Lincoln Electric IM10102 AIR VANTAGE 650 User Manual

Page 28: Typical fuel consumption, Starting the engine, Cold weather starting

STOPPING THE ENGINE

1. Switch the RUN/STOP switch to “STOP”. This turns

off the voltage supplied to the shutdown solenoid. A

backup shutdown can be accomplished by shutting

off the fuel valve located on the fuel line.

TYPICAL FUEL CONSUMPTION

Refer to Table B.1 for typical fuel consumption of the

AIR VANTAGE

®

650 CUMMINS Engine for various

operating settings.

NOTE: This data is for reference only. Fuel consumption is

approximate and can be influenced by many factors, includ-

ing engine maintenance, environmental conditions and fuel

quality.

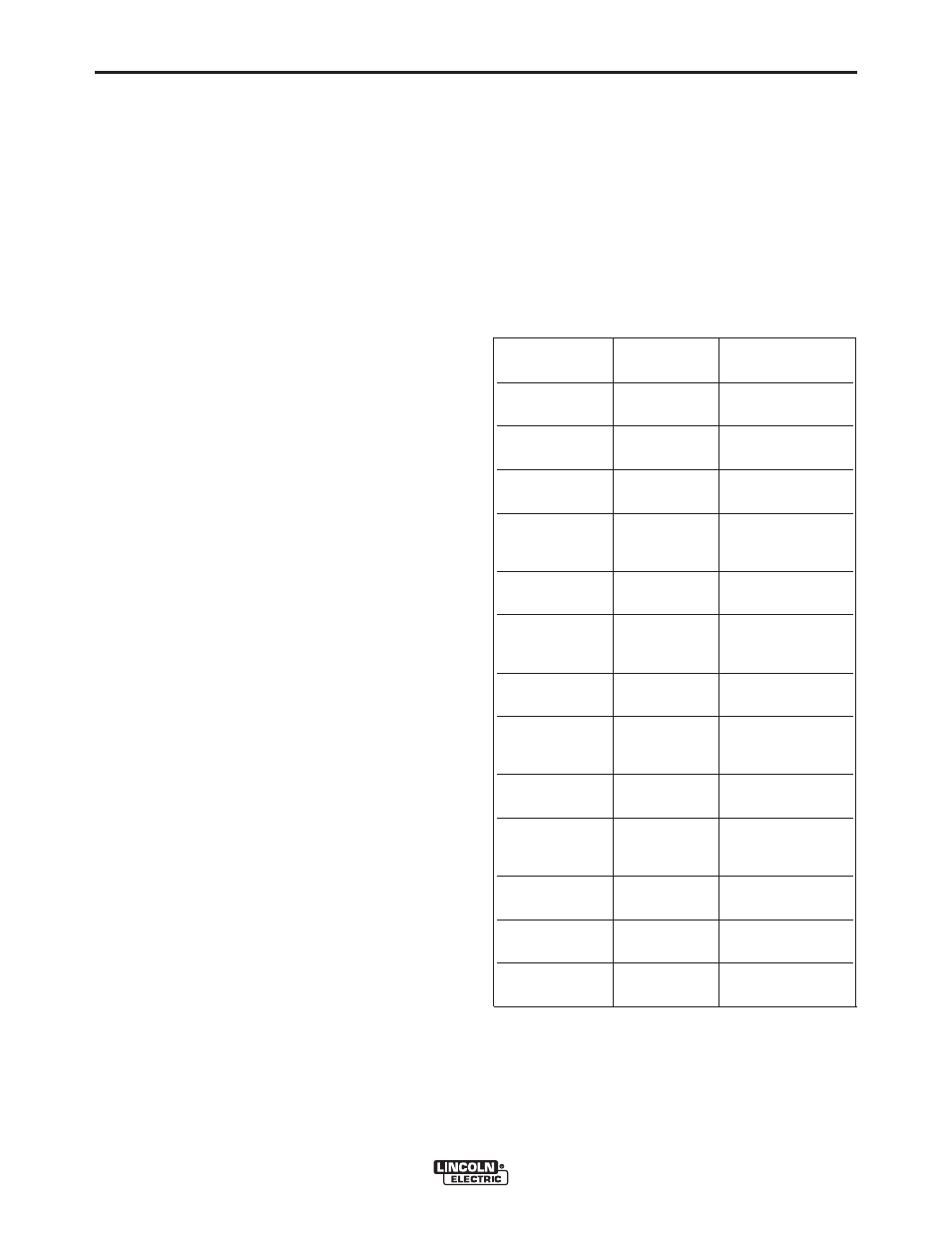

Table B.1

Cummins B3.3T Engine Fuel Consumption

Cummins B3.3T

Running Time for

69HP

25GAL.(94.6L)

(Hours)

High Idle No load

1.10 Gal./hour

22.7

1860 RPM

(4.17 L/hour)

Low Idle No load

0.72 Gal./hour

34.83

1500 RPM

(2.72 L/hour)

DC CC Weld Output

2.37 Gal./hour

10.56

500A 100% Duty Cycle

(8.96 L/hour)

DC CC Weld Output

3.10 Gal./hour

8.06

500A with Compressor

(11.74 L/hour)

100% Duty Cycle

DC CC Weld Output

2.92 Gal./hour

8.56

600A 100% Duty Cycle

(11.06 L/hour)

DC CC Weld Output

3.91 Gal./hour

6.4

600A with Compressor

(14.78 L/hour)

100% Duty Cycle

DC CC Weld Output

2.08 Gal./hour

12.02

650A 60% Duty Cycle

(7.87 L/hour)

DC CC Weld Output

2.76 Gal./hour

9.04

650A with Compressor

(10.46 L/hour)

60% Duty Cycle

DC CC Weld Output

1.70 Gal./hour

14.71

700A 40% Duty Cycle

(6.43 L/hour)

DC CC Weld Output

2.57 Gal./hour

9.74

700A with Compressor

(9.71 L/hour)

40% Duty Cycle

Aux. 7.2kva

1.28 Gal./hour

19.55

(4.84 L/hour)

Aux. 12kva

1.63 Gal./hour

15.3

(6.18 L/hour)

Aux. 20kva

2.18 Gal./hour

11.48

(8.25 L/hour)

B-7

OPERATION

B-7

ENGINE OPERATION

STARTING THE ENGINE

1. Open the engine compartment door and check that

the fuel shutoff valve located to the left of the fuel

filter housing is in the open position (lever to be in

line with the hose).

2. Make sure battery disconnect switch is in the on

position.

3. Check for proper oil level and coolant level. Close

engine compartment door.

4. Remove all plugs connected to the AC power

receptacles.

5. Set IDLER switch to “AUTO”.

6. Set the RUN/STOP switch to “RUN”. Observe that

the engine protection and battery charging lights

are on.

6a. Press Glow Plug Button and hold 15 to 20 seconds.

7. Press START button until the engine starts or for up to 10

seconds.

8. Release the engine START button when the engine

starts.

9. Check that the engine protection and battery charg-

ing lights are off. If the engine protection light is on

after starting, the engine will shutdown in a few sec-

onds. Investigate any indicated problem.

10. Allow the engine to warm up at low idle speed for

several minutes before applying a load and/or

switching to high idle. Allow a longer warm up time

in cold weather.

COLD WEATHER STARTING

With a fully charged battery and the proper weight oil,

the engine should start satisfactorily even down to

about 0°F(-18°C). If the engine must be frequently

started below 10°(-12°C), it may be desirable to install

the optional ether start kit (K887-1). For extreme cold

conditions it may be desirable to install additional

equipment such as a block heater or oil pan pad

heater, etcetera.

NOTE: Extreme cold weather starting may require

longer glow plug operations.

AIR VANTAGE

®

650 CUMMINS