Encoder mounting & installation, Figure 3b – Warner Electric CBPC-3590 User Manual

Page 6

6 Warner Electric • 800-825-9050

P-921-1 • 819-0526

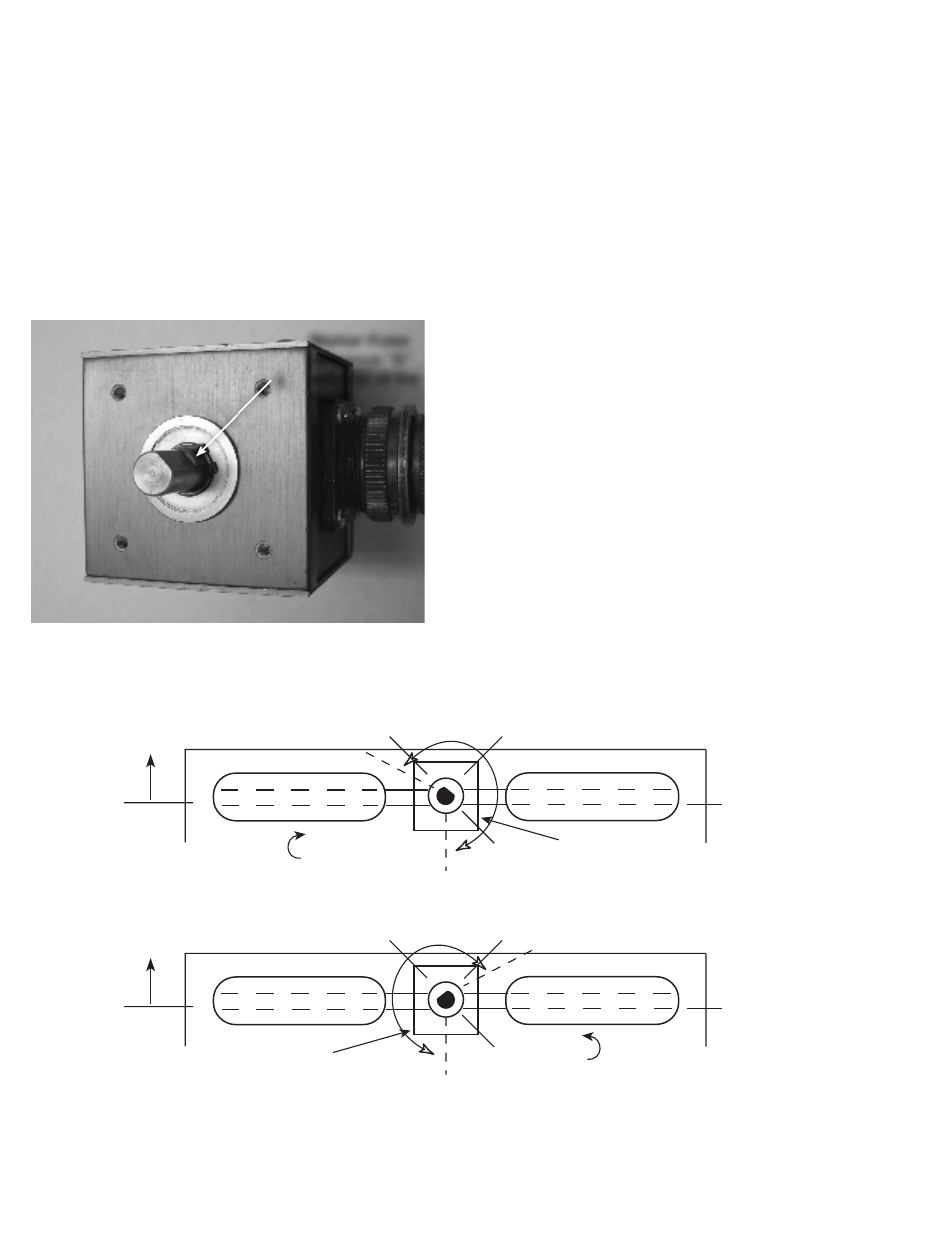

Marker Pulse Locating

Position 30° to 270°

Encoder

CW

Front

Long Axis

270

90

180

Ø

Marker Pulse Locating

Position 30° to 270°

Encoder

CCW

Front

Long Axis

270

90

180

Ø

Encoder Mounting & Installation

Normally, if the CBPC-3590 is replacing an existing

CBC1500-AHFC control, the encoder has already

been installed and set-up correctly .

For new installations follow the procedure below

referring to figures 2 and 3 for correct encoder

mounting and positioning .

q

1. Taking the encoder, position the flat on the

shaft to the position shown in Figure 2 below.

q

2 . Position the paddles on the pusher parallel to

the length of the pusher. This will be the position

the paddles are in when the pusher is static or not

rotating .

q

3. Determine if the pusher operates in a clockwise

(CW) or counter-clockwise (CCW) direction when

operating .

q

4. Mount the encoder with the bracket into the

pusher shaft keeping the shaft aligned in the

position as shown or as close as possible using

figures 3A or 3B for positioning the marker pulse

within the desired range.

q

5. Double check mounting and insure encoder is

fastened properly .

q

6. Connect encoder cable and tighten connector

securely .

q

7. This completes encoder mounting for new

application .

Note: Properly mounting the encoder in this method

insures the marker pulse will occur in the 50 to 450

pulse count range consistently . This is mandatory for

proper control operation .

Figure 2

Encoder Marker Pulse Position Reference

Figure 3a

Figure 3b

Marker Pulse

reference “X”

with flat of the

shaft

X