Nxl data sheet, Specifications, Trend control systems limited – TREND NXL Variable Speed Drives User Manual

Page 12: Trend control systems usa, Electrical, Environmental, 10 °c (no frost) to +40 °c: (i

NXL

Data Sheet

12

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37,Switzerland by its Authorized Representative, Trend Control Systems Limited.

Trend Control Systems Limited reserves the right to revise this publication from time to time and make changes to the content

hereof without obligation to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 211888 Fax:+44 (0)1403 241608 www.trend-controls.com

Trend Control Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel: (425)897-3900, Fax: (425)869-8445 www.trend-controls.com

r

e

d

r

O

e

d

o

C

y

t

il

i

b

a

d

a

o

L

r

e

w

o

P

t

f

a

h

S

r

o

t

o

M

)

W

k

(

P

t

h

g

i

e

W

)

g

k

(

w

o

L

h

g

i

H

c

a

V

0

8

3

d

e

t

a

R

s

u

o

u

n

i

t

n

o

C

I

t

n

e

r

r

u

C

L

)

A

(

%

0

1

d

a

o

l

r

e

v

o

t

n

e

r

r

u

c

)

A

(

d

e

t

a

R

s

u

o

u

n

i

t

n

o

C

I

t

n

e

r

r

u

C

H

)

A

(

%

0

5

d

a

o

l

r

e

v

O

I

t

n

e

r

r

u

C

S

)

A

(

w

o

L

C

g

e

d

0

4

)

W

k

(

P

h

g

i

H

C

g

e

d

0

5

)

W

k

(

P

5

1

0

0

0

L

X

N

9

.

1

1

.

2

3

.

1

2

5

5

.

0

7

3

.

0

0

.

1

5

2

0

0

0

L

X

N

4

.

2

6

.

2

9

.

1

9

.

2

5

7

.

0

5

5

.

0

0

.

1

5

C

/

2

C

3

0

A

A

L

X

N

3

.

3

6

.

3

2

.

2

3

.

3

1

.

1

5

7

.

0

5

5

C

/

2

C

4

0

A

A

X

N

3

.

4

7

.

4

3

.

3

5

5

.

1

1

.

1

5

5

C

/

2

C

5

0

A

A

L

X

N

6

.

5

9

.

5

3

.

4

5

.

6

2

.

2

5

.

1

5

5

C

/

2

C

7

0

A

A

L

X

N

6

.

7

4

.

8

6

.

5

4

.

8

0

.

3

2

.

2

5

5

C

/

2

C

9

0

A

A

L

X

N

9

9

.

9

6

.

7

4

.

1

1

0

.

4

0

.

3

5

5

C

/

2

C

2

1

A

A

L

X

N

2

1

2

.

3

1

9

5

.

3

1

5

.

5

0

.

4

5

5

C

/

2

C

6

1

A

A

L

X

N

6

1

6

.

7

1

2

1

8

1

5

.

7

5

.

5

1

.

8

5

C

/

2

C

3

2

A

A

L

X

N

3

2

3

.

5

2

6

1

4

2

1

1

5

.

7

1

.

8

5

C

/

2

C

1

3

A

A

L

X

N

1

3

4

3

3

2

5

3

5

1

1

1

1

.

8

5

C

/

2

C

8

3

A

A

L

X

N

8

3

2

4

1

3

7

4

5

.

8

1

5

1

5

.

8

1

5

C

/

2

C

5

4

A

A

L

X

N

6

4

1

5

8

3

7

5

2

2

5

.

8

1

5

.

8

1

5

C

/

2

C

1

6

A

A

L

X

N

1

6

7

6

6

4

9

6

0

3

2

2

5

.

8

1

c

a

V

0

4

2

o

t

8

0

2

1

C

2

0

0

0

L

X

N

4

.

2

6

.

2

7

.

1

6

.

2

7

3

.

0

5

2

.

0

0

.

1

1

C

3

0

0

0

L

X

N

7

.

3

1

.

4

8

.

2

2

.

4

5

7

.

0

5

5

.

0

9

.

1

1

C

4

0

0

0

L

X

N

8

.

4

3

.

5

7

.

3

6

.

5

1

.

1

5

7

.

0

9

.

1

1

C

6

0

0

0

L

X

N

6

.

6

3

.

7

8

.

4

2

.

7

5

.

1

2

,

1

0

.

2

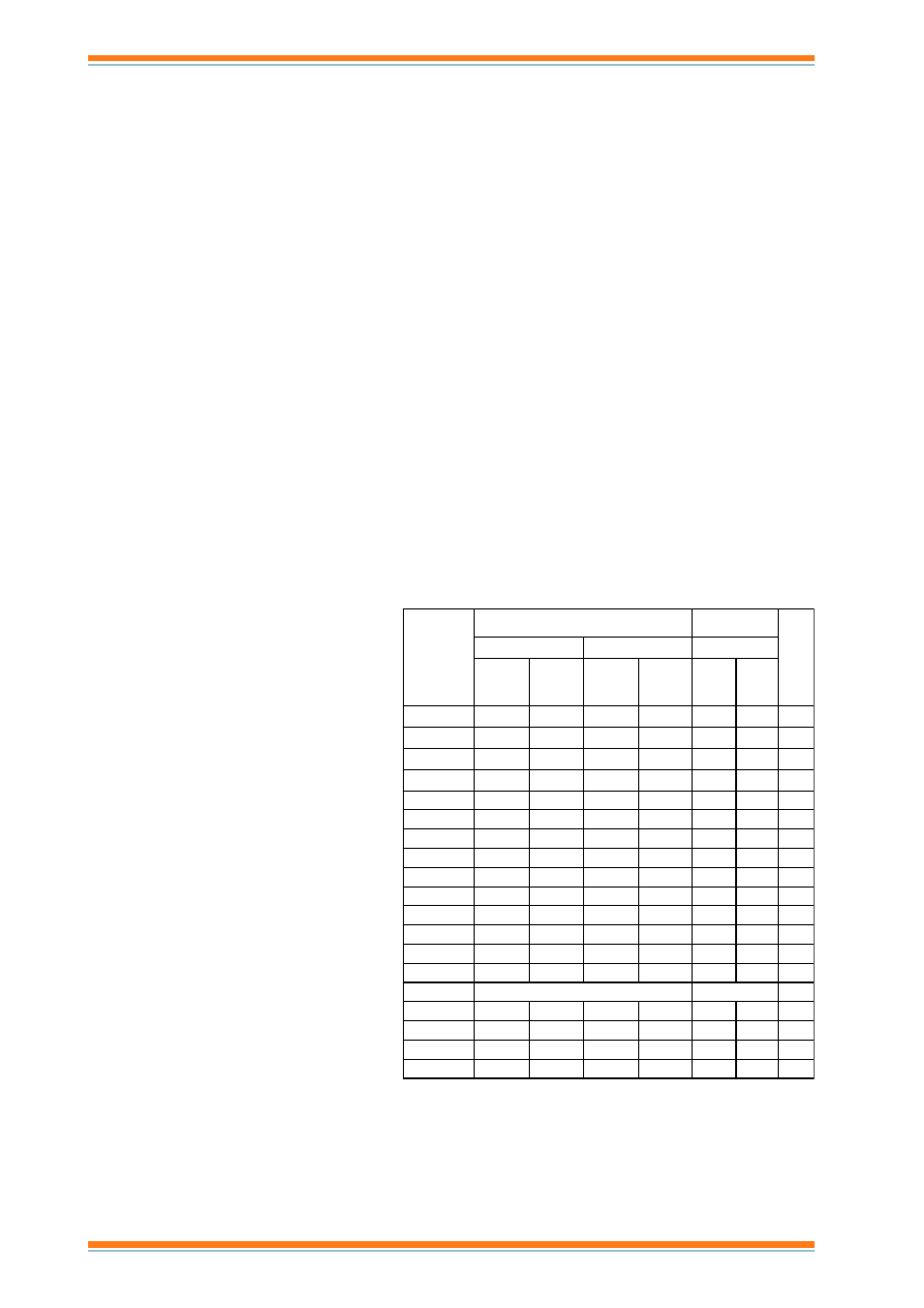

SPECIFICATIONS

Electrical

Supply voltage

Three phase units :380 to 500 Vac -15% +10% 3 phase, 45

to 66 Hz

Single phase units :208 to 240 Vac -15% +10% 1 phase, 45

to 66 Hz

Motor voltage

:0 to supply voltage

Motor current

Rated output

:I

L

, 1.9 A to 61 A dependent on option

(continuous current under low overload,

10% for 1 minute every 10 minutes, 150%

starting torque requirement, 40 °C

ambient temperature e.g. fans, pumps)

High overload

:I

H

, see table (continuous current under

high overload, 50% for 1 minute every

10 minutes, 200% starting torque

requirement, 50 °C ambient temperature

e.g. cranes, hoists, lifts)

Starting Current

:2xI

H

, (maximum current required for 2 secs

every 20 secs if output frequency <30 Hz,

and heat sink temperature <+60 °C )

Output frequency

:0 to 320 Hz

Frequency resolution :0.01 Hz

Control method

:Frequency control, Open loop

sensorless vector control

Switching frequency

:1 to 16 kHz (factory default 6 kHz)

Frequency reference

Analogue input

:Resolution 0.1% (10 bit), accuracy ±1%

Keypad reference :Resolution 0.01 Hz

Field weakening point :30 to 320 Hz

Acceleration time

:0.1 to 3000 secs

Deceleration time

:0.1 to 3000 secs

Braking torque

Environmental

Operating Temperature:-10 °C (no frost) to +50 °C: (I

H

)

-10 °C (no frost) to +40 °C: (I

L

)

Storage temperature

:-40 °C to +70 °C

Relative

humidity

:0 to 95 %RH non-condensing,

non-corrosive, no dripping water

Air quality

chemical vapours :IEC721-3-3, unit in operation class 3C2

mechanical particles

:IEC721-3-3, unit in operation

class 3S2

Altitude

100% load capacity (no derating) up to

1000 m. 1% derating for each 100 m

above 1000 m (max. 3000 m)

Vibration

:EN50178 and EN60068-2-6

Shock

:EN50178 IEC 68-2-27. UPS drop test

(for applicable UPS weights)

Enclosure class

:IP20, IP21, IP54 (see codes p9)

EMC Immunity

:EN50082-1, -2, EN61800-3

EMC Emissions

MF2, MF3

:EMC level N. Can have external filter to

achieve level H.

MF4 to MF6

:EMC level H:EN61800-3(1996) + A11

(2000) (1st environment, restricted use,

2nd environment), EN61000-4.

Safety

:Fulfils EN50178, EN60204-1, CE, UL,

cUL, FI, GOST R , IEC 61800-5 (check

nameplate for details)

DC brake

:30% T

N

(nominal torque)

without brake option

Protective Functions

Overcurrent

:Trip limit 4.0 x I

H

instantaneously

Overvoltage protection :911 Vdc

Undervoltage protection:333 Vdc

Earth fault protection

:In case of earth fault in motor or

motor cable, only the frequency

converter is protected

Other

:Unit overtemperature

protection, motor overload

protection, motor stall

protection, motor underload

protection, short circuit

protection of +24 V and +10 V

reference voltages

Inputs and Outputs

Analogue voltage input :0 to +10 V, R

in

= 200 k

Ω, single

ended. Resolution 12 bit,

accuracy ±1%

Analogue current input :0 (4) to 20 mA, R

in

= 250

Ω,

differential

Digital inputs

:3 off (Ecodrives have 6).

Positive or negative logic, 18 to

24 Vdc

Auxiliary voltage out

:+24 V ±15 %, 100 mA max.

Reference voltage out :+10 V, +3% 10 mA max.

Analogue output

:1 off. 0(4) to 20 mA, R

L

<500

Ω,

resolution 16 bit, accuracy

±1 %

Digital Output (relay)

:1 off (Ecodrives have 2).

Programmable changeover

relay max. switching capacity:

24 Vdc/8 A, 250 Vac/8 A, 125

Vdc/0.4 A.

Digital Output (open collector) :1 off (Ecodrives only).

50 mA, 48 V