System Sensor DH100ACDCLWP User Manual

Page 2

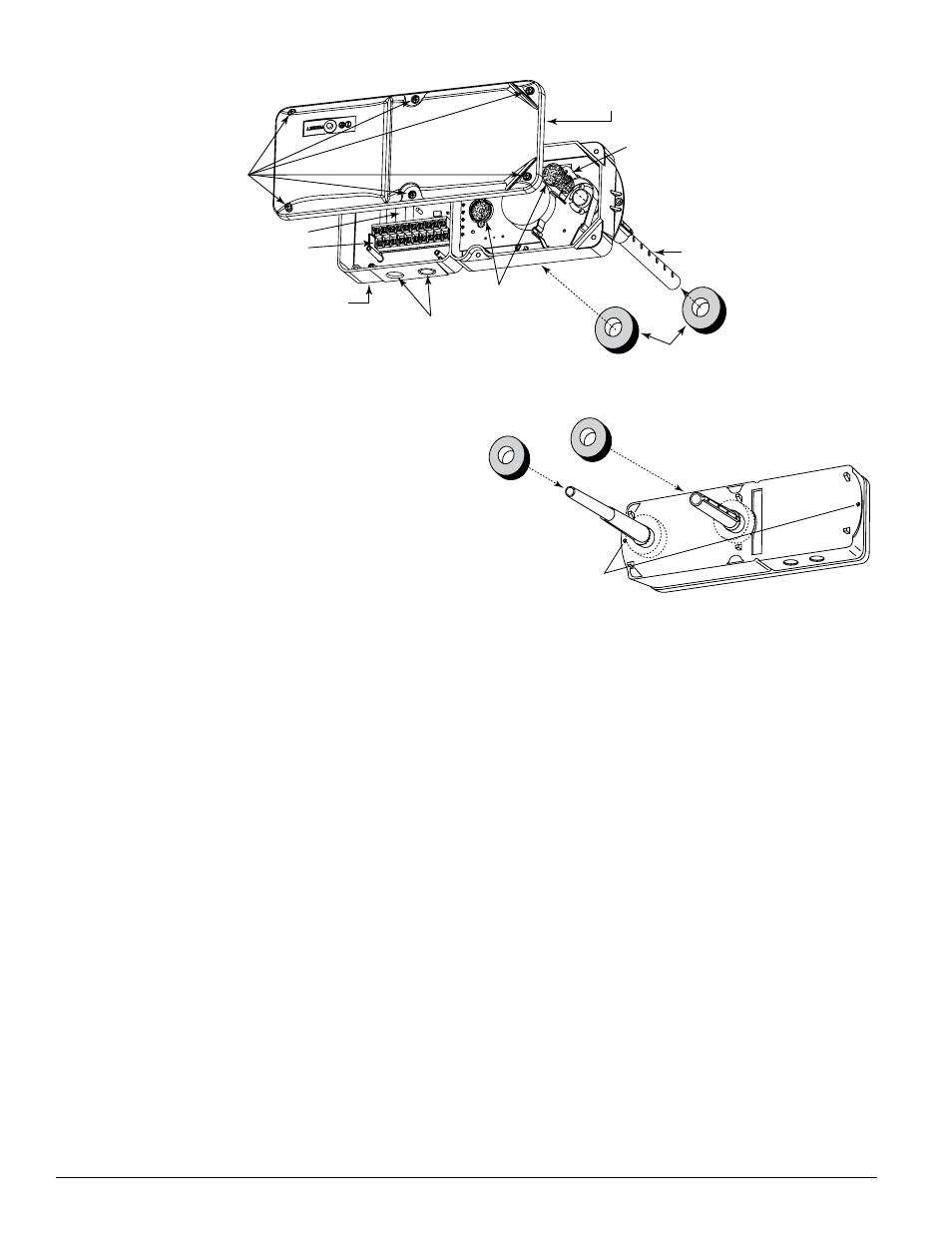

[4] Contents Of The Duct Smoke Detector Kit

1. Complete housing base and cover assembly

2. Two #10×1

1

⁄

4

˝ sheet metal screws for mounting

3. Two sampling tube filters

4. One test magnet

5. Drilling template

6. Two foam gaskets

7. Four #6-self tapping mounting screws for the metal sampling

tube and optional exhaust tube extension

8. One sampling tube end cap

9. One plastic telescoping sampling tube

10. One #8 self-tapping screw for the plastic sampling tube

NOTE: For ducts over 1

1

⁄

2

feet, longer sampling tubes must be

ordered to complete the installation. They must be the correct

length for the width of the duct where they will be installed. See

Table 1 on page 3 to determine the sampling tube required for dif-

ferent duct widths.

[5] Installation Sequence

[5.1] Verify Duct Air Flow Direction And Velocity

Model DH100ACDCLWP detectors are designed to be used in air

handling systems having air velocities of 100 to 4000 feet per min-

ute. Be sure to check engineering specifications to ensure that the

air velocity in the duct falls within these parameters. If necessary,

use a velocity meter to check the air velocity in the duct.

[5.2] Select Mounting Orientation

If possible, mount the DH100ACDCLWP with the wiring entry

hole(s) facing downwards, so that all wiring enters the hous-

ing from below. This minimizes the possibility of water entering

around the conduit fittings. Mounting the product with the wiring

entry holes on the uppermost surface should be avoided.

[5.3] Drill The Mounting Holes

Remove the paper backing from the mounting template supplied.

Affix the template to the duct at the desired mounting location.

Make sure the template lies flat and smooth on the duct. Center

punch holes A and B. Drill the holes as indicated on the template.

[5.4] Secure The Detector Housing To The Duct

Slide the foam gaskets over the tube bushings as shown in Figure

2. Use the two 1

1

⁄

4

˝ long sheet metal screws to screw the detector

housing to the duct.

CAUTION: Do not overtighten the screws.

Figure 2. Installation of foam gaskets over sampling

tube bushings:

SCREW HOLES FOR

ATTACHING HOUSING

TO DUCT WORK.

[5.5] Sampling Tube Installation

The sampling tube is identified by a series of air inlet holes on

the tube. A plastic tube is included for ducts up to 18˝ in width.

All other tubes must be ordered separately and resized for the

duct width, as specified in Table 1. It is recommended that the

sampling tube length extend at least

2

⁄

3

across the duct width for

optimal performance. The exhaust tube is molded onto the base

of the duct housing, and the A2440-00 Exhaust Tube Extension

is available as an accessory in those cases where the molded ex-

haust port does not extend at least 2 inches into the duct.

The sampling tube is always installed with the air inlet holes

facing into the air flow. To assist proper installation, the tube’s

mounting flange is marked with an arrow. Make sure the sam-

pling tube is mounted so that the arrow points into the air flow

(see

Figure 3). Figure 4 shows the various combinations of tube

mounting configurations with respect to air flow. Mounting the

detector housing in a vertical orientation is acceptable, provided

that the air flows directly into the sampling tube holes as indi-

cated in

Figure 3.

Table 1. Sampling tubes recommended for different

duct widths:

Outside Duct Width Sampling Tube Recommended*

1 to 2 ft.

ST-1.5

2 to 4 ft.

ST-3

4 to 8 ft.

ST-5

8 to 12 ft.

ST-10

*Must extend a minimum of

2

⁄

3

the duct width.

D200-24-00

2

I56-0056-009R

[3] Figure 1: Exploded View Of Duct Smoke Detector Components

FOAM

GASKETS

METAL

SAMPLING TUBE

SAMPLING TUBE

FILTERS

DETECTOR

COVER

DETECTOR BOARD

CONDUIT HOLES

DETECTOR

HOUSING

TERMINAL STRIP

POWER BOARD

COVER MOUNTING

SCREWS

H0174-00

H0107-01