System Sensor D2 User Manual

Page 5

[10] VERIfICATION Of OPERATION

[10.1] POwER ThE UNIT

Apply 12VDC or 24 VDC to terminals marked as + in and -, see Figure 1, and

electrical specs for details.

[10.2] PERfORM DETECTOR ChECk

VERIFY STANDBY per Table 2 on page 4. The use of a remote accessory is

recommended.

[10.3] SENSITIVITy VERIfICATION

The sensitivity of the sensor is confirmed to be operating within its allowable

range each time the sensor LEDs blink red every 5 seconds. Note in a mainte-

nance condition the sensor LEDs will not be illuminated as depicted in Table

2. The maintenance condition indicates that the sensor is operating outside its

original factory preset sensitivity and shall be cleaned or replaced. See Section

9 for reference. This is a valid UL test.

The SENS-RDR sensitivity reader can also be used to measure the sensitivity

of the sensor. Sensitivity testing shall not be used as a substitute for alarm

testing.

[10.4] DUCT SMOkE DETECTOR TEST AND

MAINTENANCE PROCEDURES

Test and maintain duct smoke detectors as recommended in NFPA 72. The

tests contained in this manual were devised to assist maintenance personnel

in verification of proper detector operation.

Before conducting these tests, notify the proper authorities that the smoke

detection system will be temporarily out of service. Disable the zone or system

under test to prevent unwanted alarms.

[10.4.1] ALARM TESTS

1a. M02-04-00 Magnet Test (Sold Separately) – Place the painted surface of

the magnet onto the MAGNET TEST location on the sensor cover of unit

(Figure 1).

OR

1b. Remote Test Accessory - See list on page 1.

The red LEDs on the sensor should latch on, as should any accesso-

ries (i.e. RA400Z/RA100Z, RTS451/RTS151). Verify system control panel

alarm status and control panel execution of all intended auxiliary func-

tions (i.e. fan shutdown, damper control, etc.)

2. The detector must be reset by the system control panel, or remote test

accessory

[10.4.2] VERIfy AIRfLOw TEST PER SECTION 7 hAS BEEN PER-

fORMED.

[10.4.3] SMOkE RESPONSE TESTS

To determine if smoke is capable of entering the sensing chamber, visually

identify any obstructions. Close cover tamper terminals on sensor side of

housing to ensure communication to panel. Plug the exhaust and sampling

tube holes to prevent ducted air from carrying smoke away from the detector

head, then blow smoke such as cigarette, cotton wick, or punk directly at the

head to cause an alarm. REMEMBER TO REMOVE THE PLUGS AFTER THIS

TEST, OR THE DETECTOR WILL NOT FUNCTION PROPERLY.

[10.4.4] SMOkE ENTRy USINg AEROSOL SMOkE

This test is intended for low-flow systems (100-500 FPM). If the air speed is

greater than 500 FPM, use a conventional manometer to measure differential

pressure between the sampling tubes, as described in 7.1.

Drill a

1

⁄

4

inch hole 3 feet upstream from the duct smoke detector. With the air

handler on, measure the air velocity with an anemometer. Air speed must be

at least 100 FPM. Spray aerosol smoke* into the duct through the

1

⁄

4

inch hole

for five seconds. Wait two minutes for the duct smoke detector to alarm. If the

duct smoke detector alarms, air is flowing through the detector. Remove the

duct smoke detector cover and blow out the residual aerosol smoke from the

chamber and reset the duct smoke detector. Use duct tape to seal the aerosol

smoke entry hole.

*Aerosol smoke can be purchased from Home Safeguard Industries at home-

safeguard.com, model 25S Smoke Detector Tester, and Chekkit Smoke Detector

Tester model CHEK02 and CHEK06 available from SDi. When used properly,

the canned smoke agent will cause the smoke detector to go into alarm. Re-

fer to the manufacturer’s published instructions for proper use of the canned

smoke agent.

CAUTION

Canned aerosol simulated smoke (canned smoke agent) formulas will vary

by manufacturer. Misuse or overuse to these products may have long term

adverse effects on the smoke detector. Consult the canned smoke agent man-

ufacturer’s published instructions for any further warnings or caution state-

ments.

[10.5] INSTALL ThE COVER

Install the covers making sure that the cover fits into the base groove. Tighten

the seven screws that are captured in the covers.

[11] DETECTOR CLEANINg PROCEDURES

Notify the proper authorities that the smoke detector system is undergoing

maintenance, and that the system will temporarily be out of service. Disable

the zone or system undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

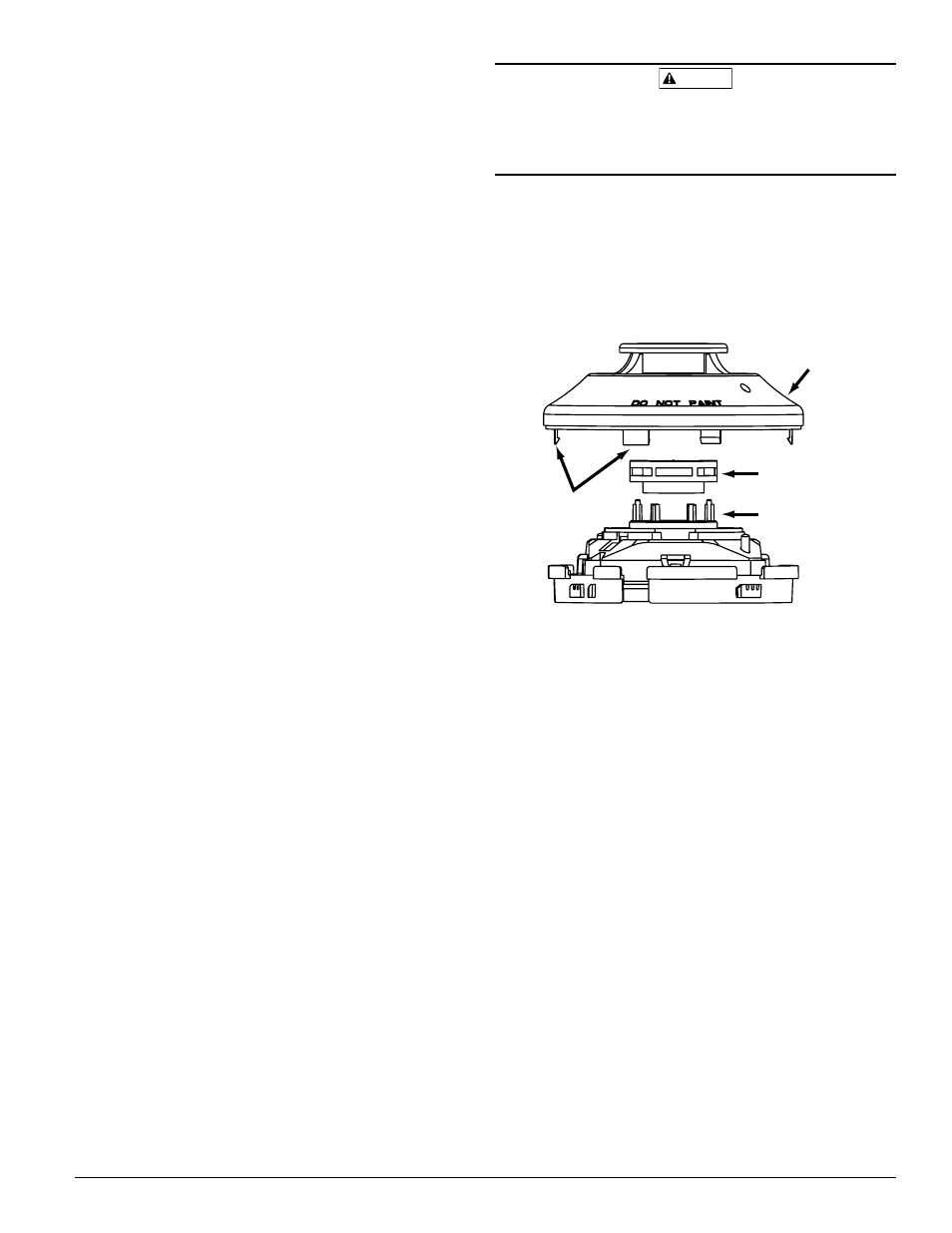

fIgURE 7. DETECTOR SENSOR ExPLODED VIEw:

SENSOR

COVER

SENSING

CHAMBER

COVER AND

SCREEN

SENSOR

CHAMBER

COVER

REMOVAL

TABS

C1009-00

[11.1] DETECTOR SENSOR

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each of the four removal

tabs that hold the cover in place. See Figure 7.

3. Vacuum the screen carefully without removing it. If further cleaning is

required continue with Step 4, otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove dust and debris from

the sensing chamber.

6. Reinstall the chamber cover/screen assembly by sliding the edge over the

sensing chamber. Turn until it is firmly in place.

7. Replace the cover using the LEDs to align the cover and then gently

pushing it until it locks into place.

8. Reinstall the detector.

[11.2] REINSTALLATION

1. Reinstall the detector in its housing.

2. Restore system power.

3. Perform Detector Check, Section [10.2].

4. Notify the proper authorities testing has been completed and the smoke

detector system is back in operation.

[12] SENSOR REPLACEMENT (PART NO. 2151)

1. Remove the sensor head by rotating counterclockwise.

2. Pull gently to remove it.

3. To replace the sensor head, align the mounting features and rotate clock-

wise into place.

SS-300-014

5 I56-3050-004R