System Sensor D2 User Manual

Page 4

tor housing, and the LOW side of the transmitter to the exhaust tube of the

duct smoke detector housing. Measure and record the voltage drop across the

1000Ω resistor (measurement 2). Subtract the voltage recorded in measure-

ment 1 from the voltage recorded in measurement 2. If the difference is greater

than 0.15 volts, there is enough air flow through the duct smoke detector for

proper operation.

fIgURE 5. PROCEDURE fOR VERIfyINg AIR fLOw:

HIGH

LOW

9 VOLT

BATTERY

9 VOLT

BATTERY

9 VOLT

BATTERY

TO SAMPLING TUBE

TO EXHAUST TUBE

DIFFERENTIAL

PRESSURE

TRANSMITTER

MODEL #607-01

15 TO 36

VDC SUPPLY

1000 OHM 5%

1 WATT RESISTOR

VOLT METER FLUKE

MODEL 87 OR

EQUIVALENT

+

–

H0163-01

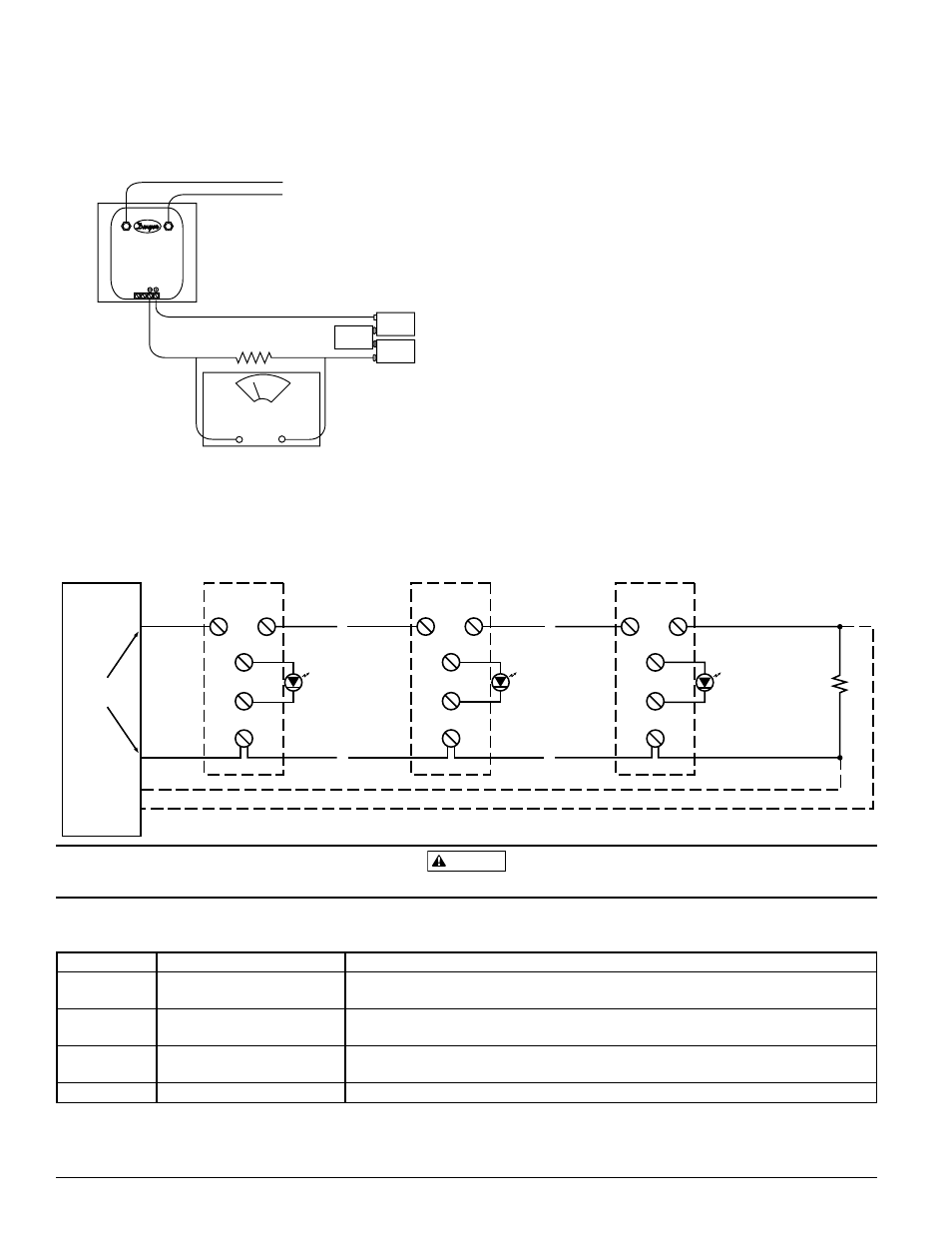

[8] fIELD wIRINg; INSTALLATION gUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and the local codes having jurisdiction. Proper wire gauges should be used.

The conductors used to connect smoke detectors to control panels and acces-

sory devices should be color-coded to prevent wiring mistakes. Improper con-

nections can prevent a system from responding properly in the event of a fire.

For signal wiring, (the wiring between interconnected detectors or from detec-

tors to auxiliary devices), it is recommended that single conductor wire be no

smaller than 18 gauge. The duct smoke detector terminals accommodate wire

sizes up to 12 gauge.

Smoke detectors and alarm system control panels have specifications for al-

lowable loop resistance. Consult the control panel manufacturer’s specifica-

tions for the total loop resistance allowed for the particular model control

panel being used before wiring the detector loop.

[8.1] wIRINg INSTRUCTIONS

The D2 detectors are designed for easy wiring. The housing provides a ter-

minal strip with clamping plates. Wiring connections are made by sliding the

bare end of the wire under the plate, and tightening the clamping plate screw.

See Figure 6 below for system wiring.

[9] DETECTOR STATUS INDICATION

Detector status is indicated by the LED’s on the sensor. Refer to table below

for more details.

SS-300-014

4 I56-3050-004R

Status

Sensor LEDs Designation

Description/Trouble Shooting

Sensor

Initialization

Alternating red blink every

5 seconds

At power up the sensor will take approximately 30 seconds to inialize. Also occurs when

sensor is removed during a seven minute delay.

Standby

Simultaneous red blink every

5 seconds

The LED on the sensor should flash approximately every 5 seconds. If the sensor LEDs

are not illuminated, then the detector lacks power (check wiring, panel or power supply).

Maintenance

Not illuminated

The sensor is outside of its sensitivity limits and shall be cleaned or replaced.

See Section 10.3 for details.

Alarm

Solid Red

The unit is in alarm.

TABLE 2. DETECTOR STATUS INDICATIONS

(+) IN

(+) OUT

(+)

(+)

(–)

(–)

1ST DETECTOR

IN LOOP D2

(–)

RA400Z (OPTIONAL)

REMOTE ALARM LED

4.4 VDC NOM.

IN ALARM

(+) IN

(+) OUT

(+)

(+)

(–)

LAST DETECTOR

IN LOOP D2

(–)

RA400Z (OPTIONAL)

REMOTE ALARM LED

4.4 VDC NOM.

IN ALARM

E

O

L

R

STYLE D OPTIONAL WIRING

UL/FM LISTED

COMPATIBLE 2-WIRE

CONTROL PANEL

ALARM

INITIATION

LOOP

(+)

(–)

EOL RESISTOR

SPECIFIED

BY PANEL

MANUFACTURER

RA

RA

RA

RA

(–)

~~

~~

(+) IN

(+) OUT

(+)

(+)

(–)

(–)

2ND DETECTOR

IN LOOP D2

(–)

RA400Z (OPTIONAL)

REMOTE ALARM LED

4.4 VDC NOM.

IN ALARM

RA

RA

~~

~~

fIgURE 6. SySTEM wIRINg DIAgRAM fOR D2 2-wIRE DUCT SMOkE DETECTORS

(DETECTORS POwERED fROM INITIATINg CIRCUIT):

CAUTION

Do not loop wire under terminals when wiring detectors. Break wire runs to provide system supervision of connections.

H0564-01