Faast configuration and validation process (cont.) – System Sensor FAAST Configuration and Validation Process User Manual

Page 2

Product specifications subject to change without notice.

2

FAAST Configuration and Validation Process (CONT.)

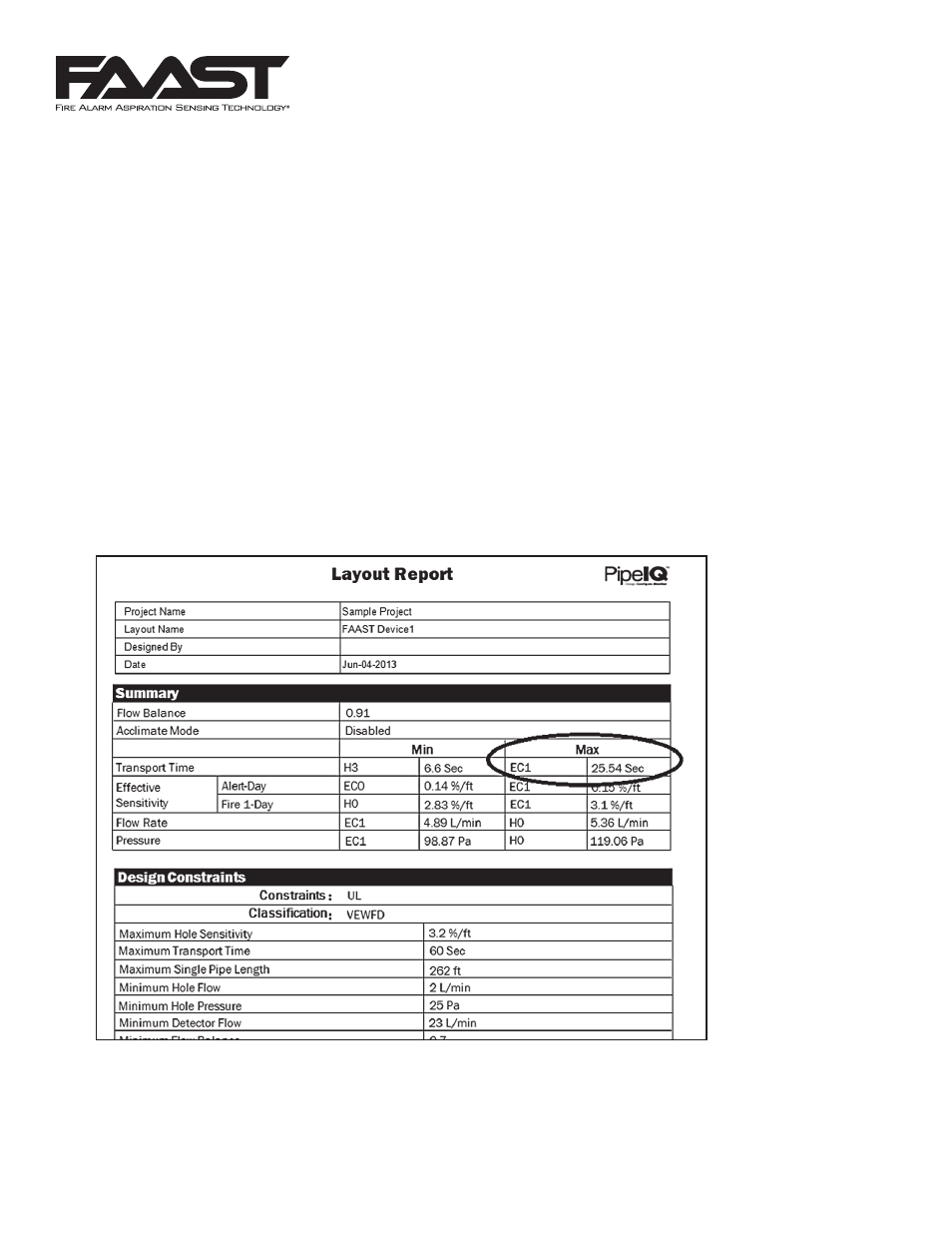

c. Compare the observed transport time with the results on the Pipe Layout report from PipeIQ. If there is more than a

20% discrepancy, verify the sample hole quantity, sizes, location, and the integrity of pipe and that the installed pipe

network is identical to the PipeIQ Pipe Layout report.

d. Once transport times for the farthest sample points are verified, test the remaining holes for airflow by introducing

smoke into each hole and verifying a response at the device or panel. Transport times are not required on each of

the remaining holes, only a verification that air is flowing.

4.

If it is required by the Authority Having Jurisdiction to verify the sensitivity of the a sampling port, a testing device that

produces a controlled level of smoke such as TruTest by SDI or similar is needed to test and provide the %/ft sensitivity

reading at the hole.

5.

Make sure to re-connect the local fire panel and any automatic extinguishing or suppressant systems after successful

completion of the test

Appendix A