LEESON Permanent Magnet AC Motors User Manual

Page 7

3.3.6.4

Thermal Protection

General Information: When thermal protection is provided,

“WITH OVERHEAT PROTECTIVE DEVICE” will be stamped on

the nameplate. The motor is provided with an overheat

protective device that does not directly open the motor circuit.

Motors nameplated with this phrase have either thermostats,

thermisters or RTDs. The leads to these devices are routed into

the motor conduit box or into an auxiliary box. The lead markings

are defined on the nameplate.

THERMOSTAT: The circuit controlled by the thermostats must

be limited to a maximum of 600 volts and 360 volt-amps. See

connection decal provided inside the terminal box cover. Failure

to connect these over temperature devices (when provided) will

void the motor warranty.

THERMISTERS OR RESISTANCE TEMPERATURE

DETECTORS (RTDs)

These sensors are to be connected to a solid state resistance

monitoring device designed for use with thermistors or RTDs

Failure to connect these over temperature devices (when

provided) will void the motor warranty.

3.3.6.5

RTD Alarm & Trip Settings

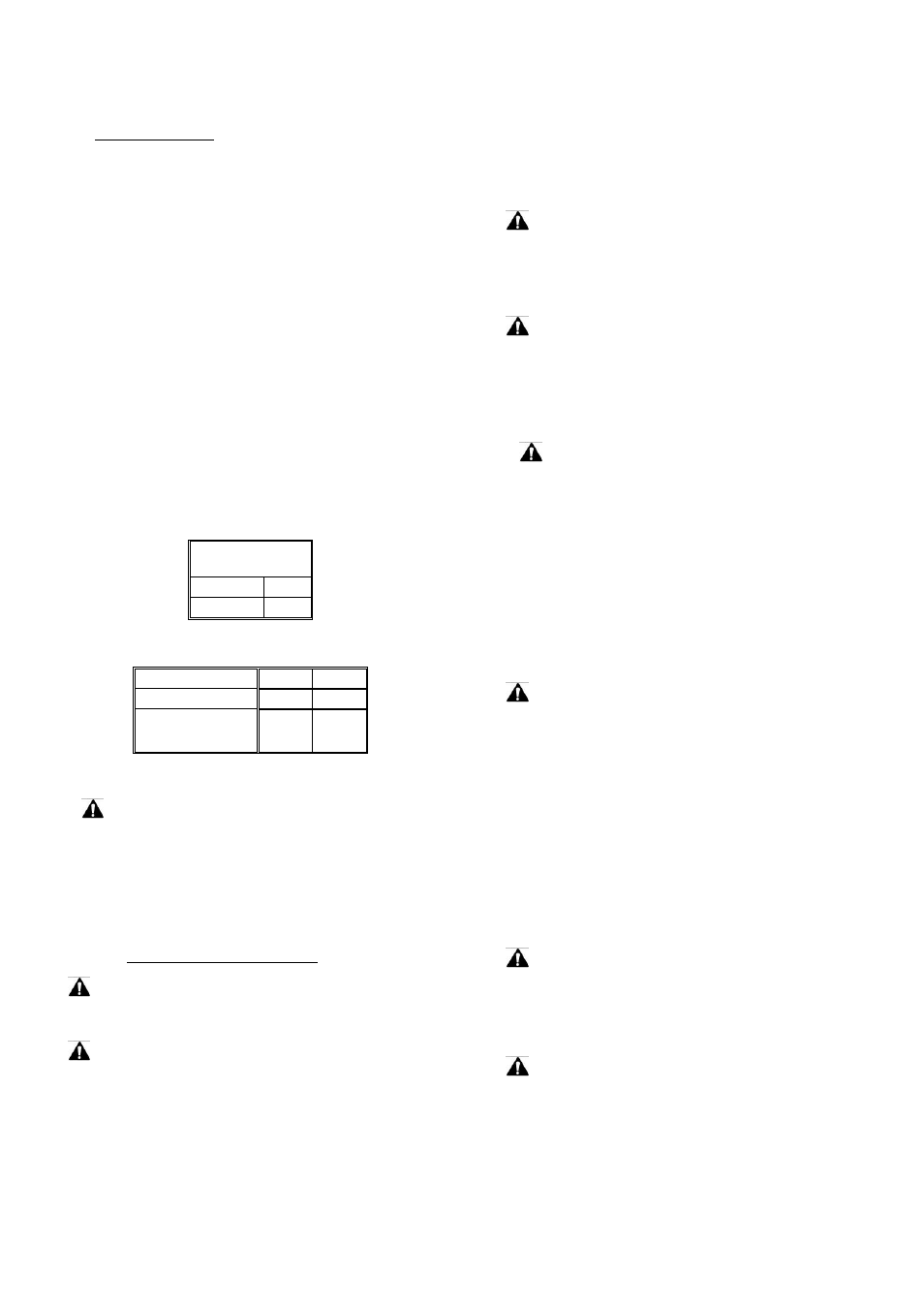

Tables 3-6 & 3-7 are suggested initial RTD alarm and trip

settings. For motors found to operate significantly below these

values the settings may be reduced accordingly.

Table 3-6 Winding RTD – Temperature Limit (

8888

C)

40

8888

C Max Ambient

Temperature

(degrees C)

Alarm

Trip

130

140

Table 3-7 Bearing RTD – Temperature Limit (

8888

C)

40

8888

C Max Ambient

Bearing Type

Alarm

Trip

Standard bearings

110

115

Motors specified

with heat stabilized

bearings to 150 C

130

135

3.3.7

GUARDS

WARNING:

ROTATING PARTS HAZARD

When devices are assembled to the motor shaft, be sure to install

protective devices such as belt guards, chain guards, and shaft

covers. These devices must protect against accidental contact with

extremities, hair, and clothing. Consider the application and provide

guarding to protect personnel. Remove all unused shaft keys and

loose rotating parts to prevent them from flying off and causing

bodily injury. Failure to follow this warning could result in serious

personal injury, death and/or property damage.

3.4

ELECTRICAL CONNECTIONS

WARNING:

ELECTRICAL HAZARDS

Before proceeding read Section 1.1 on Electrical Safety. Failure to

follow the instructions in Section 1.1 could result in serious personal

injury, death and/or property damage

WARNING:

ELECTRICAL SHOCK HAZARD: Voltage may

be present at the motor terminals even after the motor has stopped

rotating. To assure there is no voltage at motor, remove input power

from VFD and follow VFD manufacture documentation for voltage

decay time before servicing motor. Failure to follow this instruction

could result in serious personal injury or death.

NOTICE: MOTOR NOT SUITED FOR OPERATION ON LINE

POWER

Permanent magnet motors can only be properly operated by a

variable frequency drive (VFD). Attempting to run in bypass mode

(across the line) may cause motor damage.

3.4.1

POWER SUPPLY / BRANCH CIRCUIT

WARNING:

POWER SUPPLY INCOMPATIBILITY

HAZARD

Check power supply to make certain that voltage, frequency and

current carrying capacity are in accordance with the motor

nameplate and VFD. Connecting the VFD to the wrong power

source could result in serious personal injury, death and/or property

damage.

WARNING:

BRANCH CIRCUIT SUPPLY HAZARD

Motor and control wiring, fusing, overload protection, disconnects,

accessories and grounding must always conform to the applicable

electrical codes as well as local codes and sound practices.

3.4.1.1

Fuses, Breakers, Overload Relays

Consult variable frequency drive (VFD) operating manual and

applicable electric codes for branch circuit protection sizing.

WARNING:

PROTECTIVE DEVICE DISABLED HAZARD

DO NOT bypass or disable these or other protective devices.

Protection removal could result in serious personal injury, death

and/or property damage.

3.4.1.2

AC Power Supply Limits

PM motors are designed to operate with variable frequency

drives with rated input voltage 600 VAC or less. Drive RMS

output voltage should not exceed motor nameplate voltage for

which the motor is connected

.

NOTICE:

REDUCED MOTOR PERFORMANCE

Operation outside of these limits will degrade motor performance

and increase operating temperature.

3.4.2

TERMINAL BOX

WARNING:

ELECTRICAL SHOCK HAZARD

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not open terminal box or

touch unprotected terminals while the motor shaft is rotating.

Failure to do so may cause serious injury or death to personnel.

3.4.2.1

Conduit Opening

For ease of connections, motors are typically provided with large

terminal boxes. Most motors have conduit access in 90 degree

increments, the terminal box conduit opening is typically provided

via knockouts, holes with covers, or the terminal box is rotate-

able. Fabricated conduit boxes may have a removable plate for

the installer to provide correctly sized hole(s).

3.4.3

LEAD CONNECTIONS

Electrical connections are to be made per nameplate connection

diagram or separate connection plate.

In making connections follow

the applicable electrical code as well as local codes and practices.

WARNING:

ELECTRICAL CONNECTION HAZARD

Failure to correctly connect the motor leads and grounding

conductor can result in serious personal injury or death. Motor lead

connections can short and cause damage or injury if not well

secured and insulated.

3.4.4

GROUND CONNECTION(S)

WARNING:

ELECTRICAL GROUNDING HAZARD

For general information on grounding (USA) refer to NEC Article

250. Improper grounding of an inverter fed motor may result in

frame voltages in excess of 500 Volts. In making the ground

connection, the installer must make certain that a good electrical

connection is obtained between motor and grounding lead. Failure

to properly ground motors, per the applicable national code (such

as NEC Article 430) and local codes may cause serious injury or

death to personnel.