LEESON AC Induction Motors User Manual

Lubrication instructions for ball bearing motors

Lubrication

This motor is supplied with pre-lubrication ball bearings. No lubrication required before start up.

Relubrication Intervals

The following intervals are suggested as a guide:

Lubrication

Use high quality ball bearing lubricant. Use consistency of lubricant suitable for class of insulation stamped on

nameplate as follows:

Procedure

If motor is equipped with Alemite fitting, clean tip of fitting and apply grease gun. Use 1 to 2 full strokes on

motors in NEMA 215T frame and smaller. Use 2 to 3 strokes on NEMA 254T thru NEMA 365 T frame. Use 3

to 4 strokes on NEMA 404T frames and larger. On motors having drain plugs, remove drain plug and operate

motor for 20 minutes before replacing drain plug.

On motors equipped with slotted head grease screw, remove screw and apply grease tube to hole. Insert 2 to

3 inch length of grease string into each hole on motors in NEMA 215T frame and smaller. Insert 3 to 5 inch

length on larger motors. For motors having drain plug and operate motor for 20 minutes before replacing drain

plug.

CAUTION:

Keep lubricant clean. Lubricate motors at standstill. remove and replace drain plugs at standstill. Do

not mix petroleum lubricant and silicone lubricant in motor bearings.

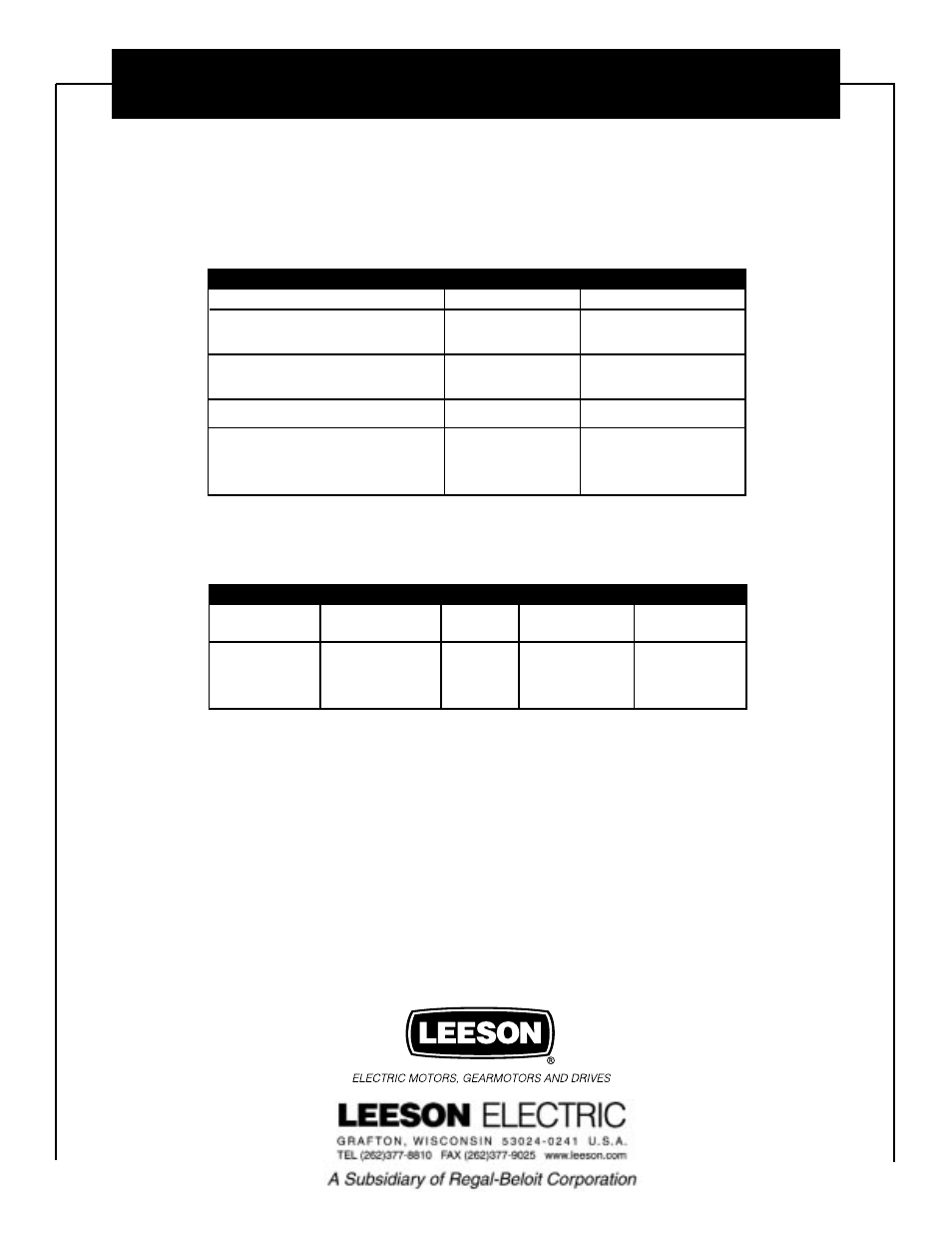

Lubrication Instructions

For Ball Bearing Motors

H.P. RANGE

Sub Fractional to 7 1/2

10 to 40

50-200

Sub Fractional to 7 1/2

10 to 40

50 to 200

All

Sub Fractional to 40

50 to 200

SUGGESTED RELUBRICATION INTERVALS

HOURS OF SERVICE PER YEAR

5,000

Continuous Normal Applications

Season Service Motor

Idle 6 Months or More

Continuous High Ambients

Dirty or Moist Locations

High Vibrations

Where Shaft End is Hot (Pumps-Fans)

RELUBE INTERVAL

5 Years

3 Years

1 Year

2 Years

1 Year

9 Months

1 Year

(Beginning of Season)

6 Months

3 Months

300-088.02

CONSISTENCY

Medium

LUBRICATION CONSISTENCY

INSULATION

CLASS

B & F

F & H

TYPICAL

LUBRICATION

Shell Dolium R

and/or

Chevron SR1 2

FRAME

TYPE

Sub Fractional

to 447T

All

TYPE

Polyurea