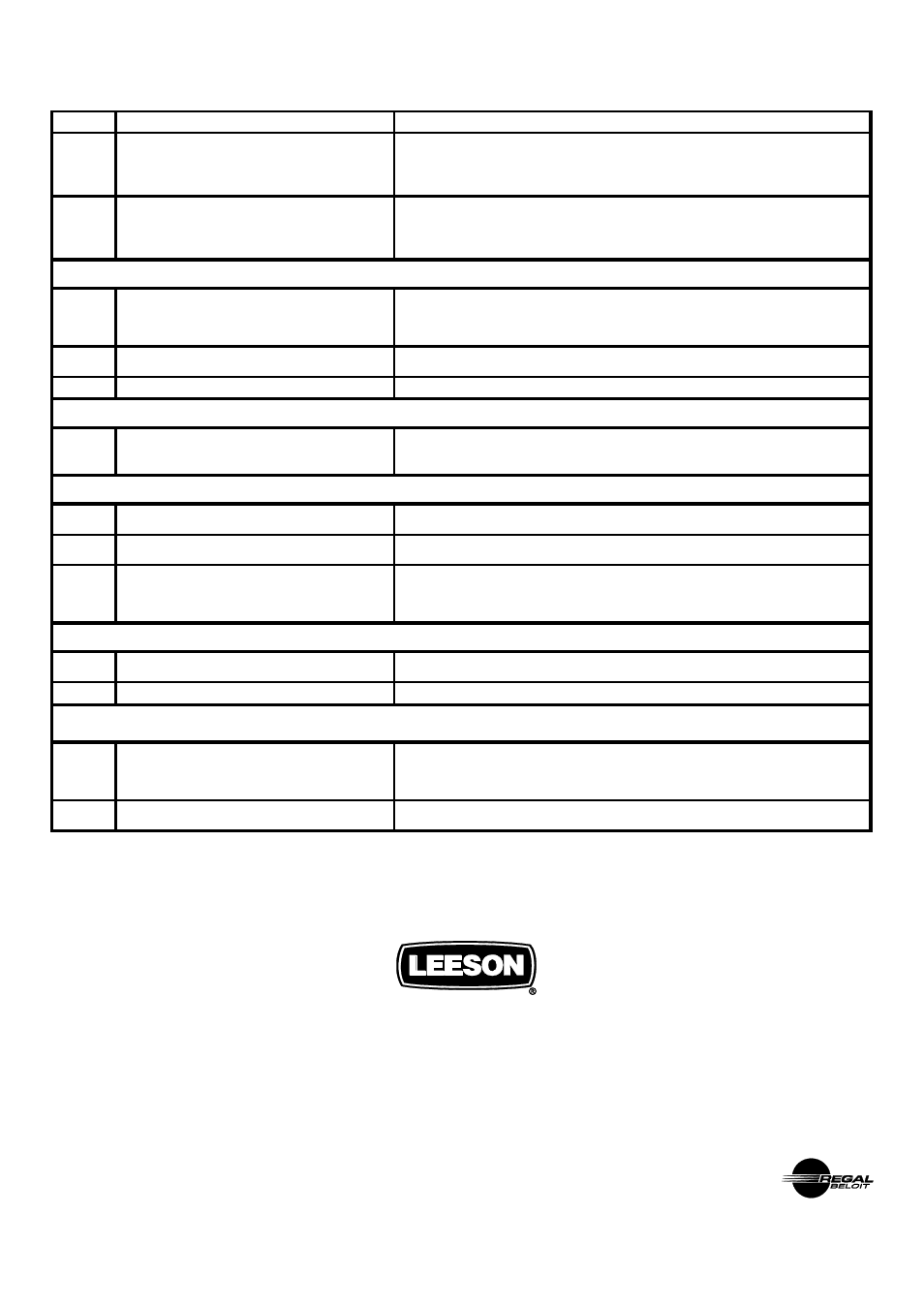

Bearings repeatedly fail, Vfd trips on ground fault, Motor shaft cogs – LEESON Permanent Magnet AC Motors User Manual

Page 12: Vfd trips during deceleration

E

Uneven, weak or loose mounting support.

Shim, strengthen or tighten where required.

F

Motor bearings worn.

Uncouple motor from load and rotate shaft by hand. Ref section 2.1.2. If you hear

noise or feel roughness, have bearings replaced. Ref Section 4.0. For motors with

regreasing provisions, add grease per relubricating instructions. Ref. Section 4.2.3. If

noise persists contact motor manufacturer.

G

Motor out of balance.

Motor is balanced at the factory and will remain balanced in operation. If motor balance

is in question, remove motor from application and send to a motor manufacturer

authorized service shop for inspection. Do not attempt to disassemble motor in the

field.

Bearings repeatedly fail

A

Load to motor may be excessive or unbalanced.

(1) If belt drive, check system per section 3.3.4.

(2) Other than belting, check loading on motor shaft. An unbalanced load will also cause

the bearings to fail.

(3) Check run-out of mating components, such as a C-face and pump flange.

B

Bearings contaminated.

Motor enclosure not suitable for environment. Replace with correct enclosure

construction.

C

Incorrect grease or bearings for ambient extremes. See section 4.2.1.

Motor makes a rubbing, grinding, or squealing noise

A

Contact between rotating and stationary

components.

Isolate motor from load. To locate point of contact turn motor shaft by hand. Ref.

Section 2.1.2. If point of contact is not located, contact motor manufacturer authorized

service shop.

VFD trips on Ground Fault

A

VFD trips at low speed during starting. Voltage

boost is set too high.

Reduce boost, repeat auto tune.

B

Condensation forms on motor winding.

Remove source of moisture. Dry out motor. Add space heaters to motor. Ref. Section

3.3.6.3 and 4.0.

C

Motor winding is shorted to ground.

Disconnect leads at motor conduit box and Megger motor leads to ground. Ref. Section

4.1.2. If resistance is less than 1.5 mega-ohms, remove motor from service. Service

shop must check for excessive moisture or contamination on windings or short to

ground.

Motor shaft cogs

A

Shaft cogs when turned by hand.

Motor leads are shorted together inside conduit box producing braking torque. Isolate all

leads and repeat shaft turning by hand. Ref. Section 3.4.5.1.

B

Shaft cogs when operated by VFD.

Voltage boost is excessive. Reduce boost. Repeat auto tune.

VFD trips during deceleration

A

VFD cannot absorb regenerated power.

(1) Add dynamic brake resistors or change VFD to line-regenerative design. For multi-

drive installations, connect drives in common bus configuration to share regenerated

power.

(2) Increase capacity of dynamic braking circuit.

B

Deceleration time is set too fast. VFD’s dynamic

braking circuit overloads.

Increase deceleration time to reduce regenerated energy.

Form 5968L

7/2011 R1

A Regal Beloit Company

2100 Washington St.

•

Grafton, WI 53024

Ph: (262) 377-8810

•

Fax: (262) 377-9025

www.leeson.com