LEESON Permanent Magnet AC Motors User Manual

Page 3

1.3

ENVIRONMENTAL SAFETY

WARNING:

HAZARDOUS LOCATIONS

The NEC and the local authority having jurisdiction must be consulted

concerning the installation and suitability of motors for use in

Hazardous Locations, in accordance with NEC Article 500. The local

authority having jurisdiction must make the final determination of what

type of motor is required. The application and operation is beyond the

control of the motor manufacturer. Failure to do so may cause serious

injury or death to personnel.

2.0 RECEIVING AND INSPECTION

2.1

INITIAL INSPECTIONS

WARNING:

ELECTRICAL SHOCK HAZARD

Shaft rotation produces voltage at motor leads and connected

equipment even when motor is disconnected from power source. Do

not open terminal box or touch unprotected terminals while the motor

shaft is rotating. Failure to do so may cause serious injury or death to

personnel.

2.1.1

CHECK PACKING LIST AND INSPECT

the

packaging to make certain no damage has occurred in shipment.

If there is visible damage to the packaging, unpack and inspect

the motor immediately. Claims for any damage done in shipment

must be made by the purchaser against the transportation

company.

2.1.2

TURN MOTOR SHAFT

(see Electrical Shock Hazard

above) by hand to be certain that it rotates freely.

Note: Motor will

not turn freely if leads are shorted together. User may feel small

pulsations when turning shaft due to the magnets in rotor. Shaft

seals and bearing seals may add drag.

CAUTION:

Observe caution when working near threads or

keyways. Finger or ring contact may cause injury.

2.1.3

CHECK NAMEPLATE

for conformance with purchase

order requirements and compliance with power supply and control

equipment requirements.

2.2

HANDLING

WARNING:

FALLING OBJECT HAZARD

Eyebolts or lifting lugs, where provided, are intended for lifting only the

motor and accessories mounted by the motor manufacturer (unless

specifically stated otherwise on the motor). Utilizing the motor lifting

provision to lift other components such as pumps and gear boxes

could result in serious personal injury, death and/or property damage.

WARNING:

FALLING OBJECT HAZARD

Before using the lifting provision, check the eyebolts and/or other lifting

means to assure they are not bent or damaged and are completely

threaded, seated & secured to the motor. Equipment to lift motor must

have adequate lifting capacity. While lifting the motor, DO NOT stand

under or in the vicinity of the motor. Failure to follow these instructions

could result in serious personal injury, death and/or property damage.

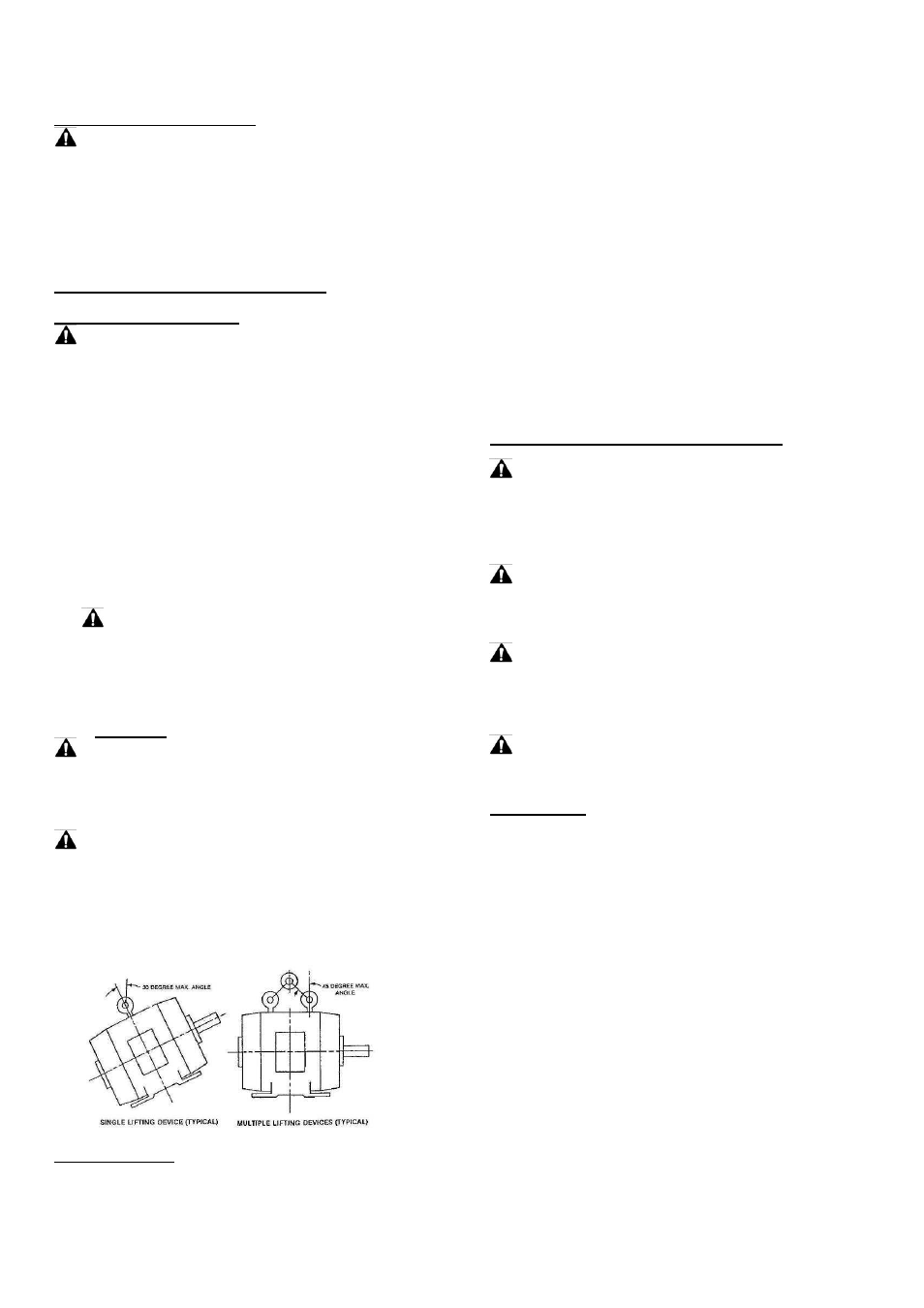

2.2.1 LIFTING ANGLE LIMITATIONS

2.3

STORAGE:

Motors, not put into service immediately, must

be stored indoors in a clean, dry location. Avoid locations with large

temperature swings that will result in condensation. Motors must be

covered to eliminate airborne dust and dirt.

If the storage location

exhibits high vibration, place isolation pads under motor to minimize

damage to motor bearings.

2.3.1

BEARING LUBRICATION:

Bearings are grease

packed at the factory; relubrication upon receipt of motor or while

in storage is not necessary. If stored more than one year, add

grease per lubrication instructions (Table 4-4) before start-up.

2.3.2

SHAFT ROTATION:

(see Electrical Shock Hazard

Warning in section 2.1) It is recommended that the motor shaft be

rotated 5 to 10 rotations every three months to distribute the

grease in the bearings. This will reduce the chance for corrosion

to form on the bearing rolling elements and raceways. Note: User

may feel small pulsations when turning shaft due to the magnets

in rotor. Shaft seals and bearing seals may add drag.

2.3.3

DAMP OR HUMID STORAGE LOCATIONS:

Treat

unpainted flanges, shafts, and fittings with a rust inhibitor. Apply

appropriate power to the motor’s space heaters (if so equipped).

3.0 INSTALLATION AND OPERATION

WARNING:

ELECTRICAL SHOCK HAZARD

Only qualified personnel who are familiar with and understand the

appropriate national codes, local codes and sound practices should

install or repair electrical motors and their accessories. Installation

should conform to the appropriate national code as well as local codes

and sound practices. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

WARNING:

ELECTRICAL LIVE CIRCUIT HAZARD

Do not touch electrically live parts. Disconnect, Lockout and Tag input

power supply before installing or servicing motor (includes accessory

devices). Use a voltmeter to verify that power is off before contacting

conductors.

WARNING:

ELECTRICAL SHOCK HAZARD

Shaft rotation produces voltage at PM motor leads and connected

equipment even when motor is disconnected from power source. Do

not open terminal box or touch unprotected terminals while the motor

shaft is rotating. Failure to do so may cause serious injury or death to

personnel.

WARNING:

ELECTRICAL SAFETY

Refer to Section 1.0 for additional warnings before proceeding with

installation and operation.

3.1

LOCATION

3.1.1

SELECTING A LOCATION:

Consideration should be

given to environment and ventilation. Motors should be installed

in an area that is protected from direct sunlight, corrosives,

harmful gases or liquids, dust, metallic particles, and vibration. A

motor with the proper enclosure for the expected operating

condition should be selected. Provide accessible clearance for

cleaning, repair, service, and inspections (See section 3.1.3 for

construction clearances). The location should be considered for

possible future motor removal or motor handling. The free flow of

air around the motor should not be obstructed.

3.1.2

AMBIENT TEMPERATURE LIMITS:

The ambient

temperatures of the air inlet to the motor should not exceed 40°C

(104°F) or be less than -30°C (-22°F) unless the mo tor nameplate

specifically states an ambient temperature outside of these limits.

The ambient inside an enclosure built around the motor shall not

exceed the nameplate ambient. For ambient temperatures outside

of these limits consult the motor manufacturer.

NOTICE:

INSULATION DEGRADATION WARNING

Insulation at high temperatures ages at an accelerated rate. Each

10°C increase in temperature reduces the insulation life by one

half.