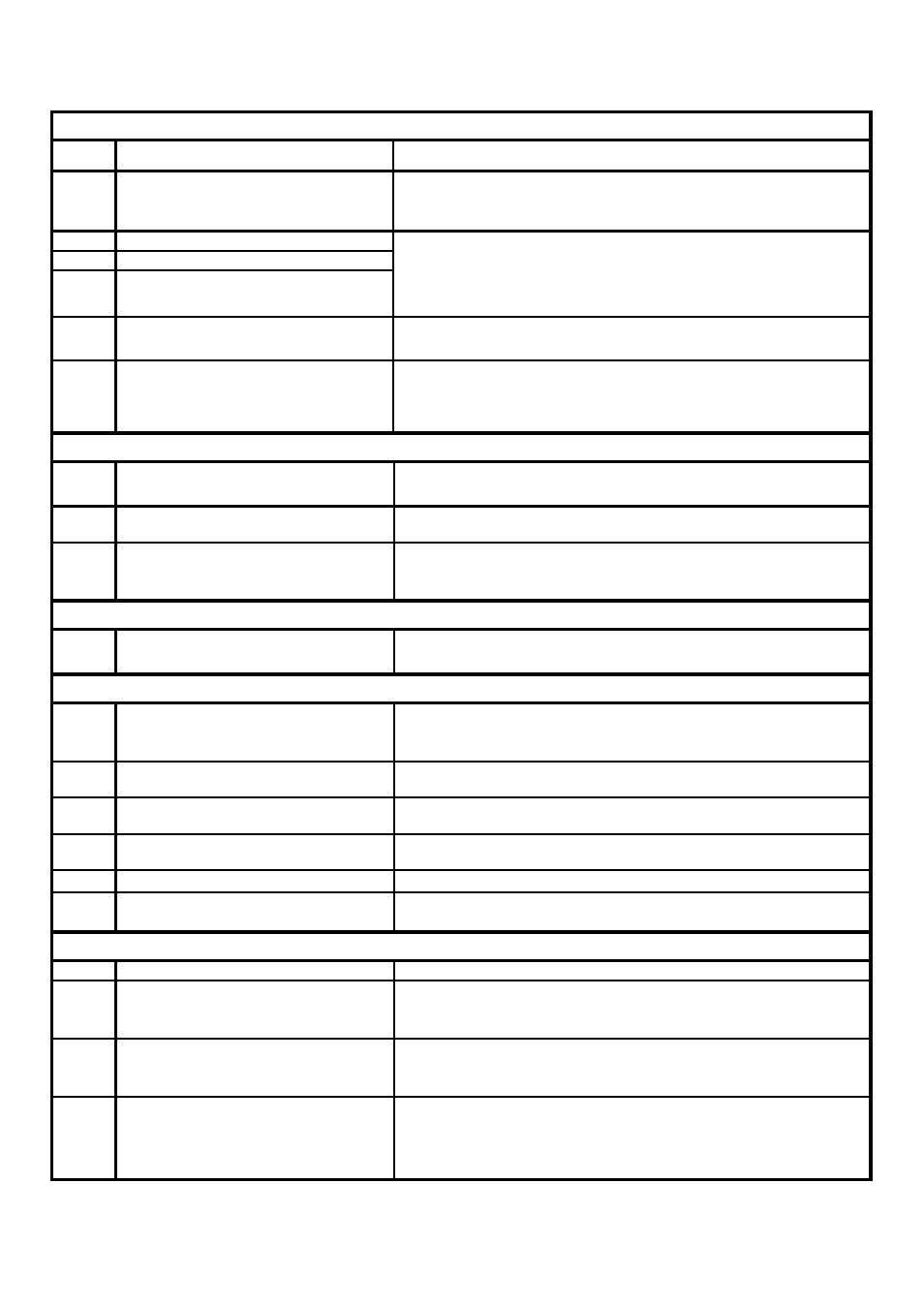

Motor takes too long to accelerate, Motor rotates in the wrong direction, Motor vibrates – LEESON Permanent Magnet AC Motors User Manual

Page 11

Motor has been running, then slows down, stalls, or fails to restart

A

Drive has faulted.

Check fault codes on VFD and follow VFD troubleshooting procedures. Ref Section

3.3.5.

B

Supply voltage to VFD has drooped or has

become severely unbalanced.

(1) Check fuse or reset circuit breaker. Ref. Section 3.4.1.1.

(2) Verify that rated and balanced supply voltage has been restored at VFD input before

restarting motor. Measure VFD input voltage after motor has reached set speed during

restart. Ref. Section 3.4.1.2.

C

Motor is overloaded. VFD trips on overload.

(1) Verify that motor & load turn freely. Ref. Sections 3.3.5 and 3.4.5.

(2) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

(3) Verify that motor starts when disconnected from load. Ref. Section 3.4.5.

(4) Remove excessive / binding load if present.

(5) Motor may have overheated. Check thermostats and if tripped, allow motor to cool

before attempting to restart. Ref. Section 3.3.6.4.

D

Motor bearings are seized.

E

Load Is jammed. VFD trips on overload.

F

VFD will not restart motor after tripping.

(1) Check fault codes on VFD and follow VFD troubleshooting procedures.

(2) Verify that VFD input voltage is balanced and within limits. Ref. Section 3.4.1.

(3) Remove excessive mechanical load if present.

G

Rotor magnets have been partially demagnetized

due to excessive heat or excessive current.

To diagnose, motor must be cooled to room temperature. Disconnect motor shaft from

load and motor leads from VFD. Ref. Section 4.0. Connect AC volt meter across T1

and T2 motor leads. Drive motor at a speed below rated speed and measure both

voltage generated and actual RPM. The voltage per 1000 rpm should match the

nameplate value within 10%.

Motor takes too long to accelerate

A

Acceleration rate set too long.

(1) Decrease acceleration setting in VFD.

(2) Make sure motor is wired to match VFD output voltage.

(3) Verify motor nameplate voltage matches VFD output voltage. Ref. Section 3.4.1.2.

B

Supply voltage has drooped or become severely

unbalanced.

Ensure that steady state supply voltage at VFD input terminals is within limits. Ref.

Section 3.4.1.2. Correct as needed.

C

Load exceeds motor/VFD capability.

(1) Verify the motor rating and VFD current capability are sized correctly for the load.

(2) Set current / torque limit setting to match the maximum motor capability. Ref.

Section 3.4.5.

(3) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

Motor rotates in the wrong direction

A

Motor lead wiring is reversed or commanded

direction is reversed at VFD.

(1) Interchange any two motor leads between motor and VFD output terminals. Ref.

Section 4.0.

(2) Program direction change in VFD.

VFD trips repeatedly on overload or motor over-temperature fault

A

Load exceeds motor/VFD capability.

(1) Verify the motor rating and VFD current capability are sized correctly for the load.

(2) Set current / torque limit setting to match the maximum motor capability. Ref.

Section 3.4.5.

(3) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

B

Ambient temperature too high.

Confirm that ambient at motor does not exceed value stamped on motor nameplate.

Reduce ambient as needed. Ref. Section 3.1.2.

C

Motor cooling fins and/or vent openings blocked.

Remove foreign materials – clear vent openings, fan guard air inlets and frame fins

(TEFC motors). Ref. Section 4.1.1.

D

Insufficient Air Flow.

TEAO (Totally Enclosed Air Over) motors: Measure airflow next to motor surface and

obtain minimum requirements from motor manufacturer. Ref. Section 3.1.3.1.

E

Load acceleration time is set too short.

Increase acceleration time as needed.

F

Start/stop time (duty cycle) is too short or too

frequent.

(1) Increase acceleration/deceleration times.

(2) Reduce the number of start/stop cycles.

Motor Vibrates

A

Motor misaligned to load.

Realign load.

B

Load out of balance.

(1) Ensure that load is dynamically balanced.

(2) Verify that motor shaft is not bent. Uncouple motor from load and inspect motor

shaft. Rule of thumb is 0.002” runout for shafts extension lengths up to 3.00”. Add

0.0005” per every additional inch of shaft length beyond 3.00”.

C

Uneven tension on multiple belts.

(1) Belts are not evenly worn. Realign motor to load and replace all belts. Ref. Section

3.3.4.

(2) A mix of new and used belts is used. Replace multiple belt applications with a

complete set of matched belts. Ref. Section 3.3.4.

D

Driven load operating at resonant point / natural

frequency.

(1) De-energize motor and record vibration as load coasts from 100% speed to 0 RPM.

If vibration drops immediately, vibration source is electrical. If levels do not drop

immediately, source is mechanical.

(2) If electrical sources, program skip frequencies to bypass resonant points.

(3) If mechanical, redesign system to operate below the resonant point.