KB Electronics KBRG-255 User Manual

Page 8

4

II.

SETTING MODE OF DRIVE (SPEED OR TORQUE CONTROL).

The KBRG-255 can be operated as a speed control or torque control by setting the position

of jumper J7. The main speed potentiometer controls the magnitude of the mode selected.

Set jumper J7 to "SPD" for speed control or to "TRQ" for torque control. (See fig. 1, p. 3.)

A. Speed Control Mode – When jumper J7 is set to the “SPD” position, the KBRG-255 will

vary the motor speed as a function of the voltage on input terminals "12" (signal) and "13"

(common). IMPORTANT: When J7 is set for speed control (“SPD”), J8 must be set to

“S/LT” position (factory setting). The input voltage can be derived from the wiper of the

main speed potentiometer or from an isolated analog input (voltage following mode). Since

the KBRG-255 is a 4-quadrant regenerative drive, the motor speed will follow both a

positive and negative wiper voltage and drive the motor in both the forward direction and

reverse direction. In addition, it will apply both forward and reverse torque in order to

stabilize motor speed.

To understand the concept of a regenerative drive, the operation of an elevator can be used.

If one were to enter the elevator on the first floor and press 10, the motor and control would

have to lift the elevator against gravity. In this mode, the drive would operate like a

conventional speed control which is called “motoring” (the applied load is opposite to the

direction of motor rotation). When the elevator is at floor 10 and floor 1 is pressed, gravity will

try to pull the elevator car down faster than the speed for which it is set. The control will then

provide reverse torque to keep the car form falling faster than the set speed. This operation

is regeneration (the applied load is in the same direction as the direction of motor rotation).

Table 3 summarizes the different modes of regen operation.

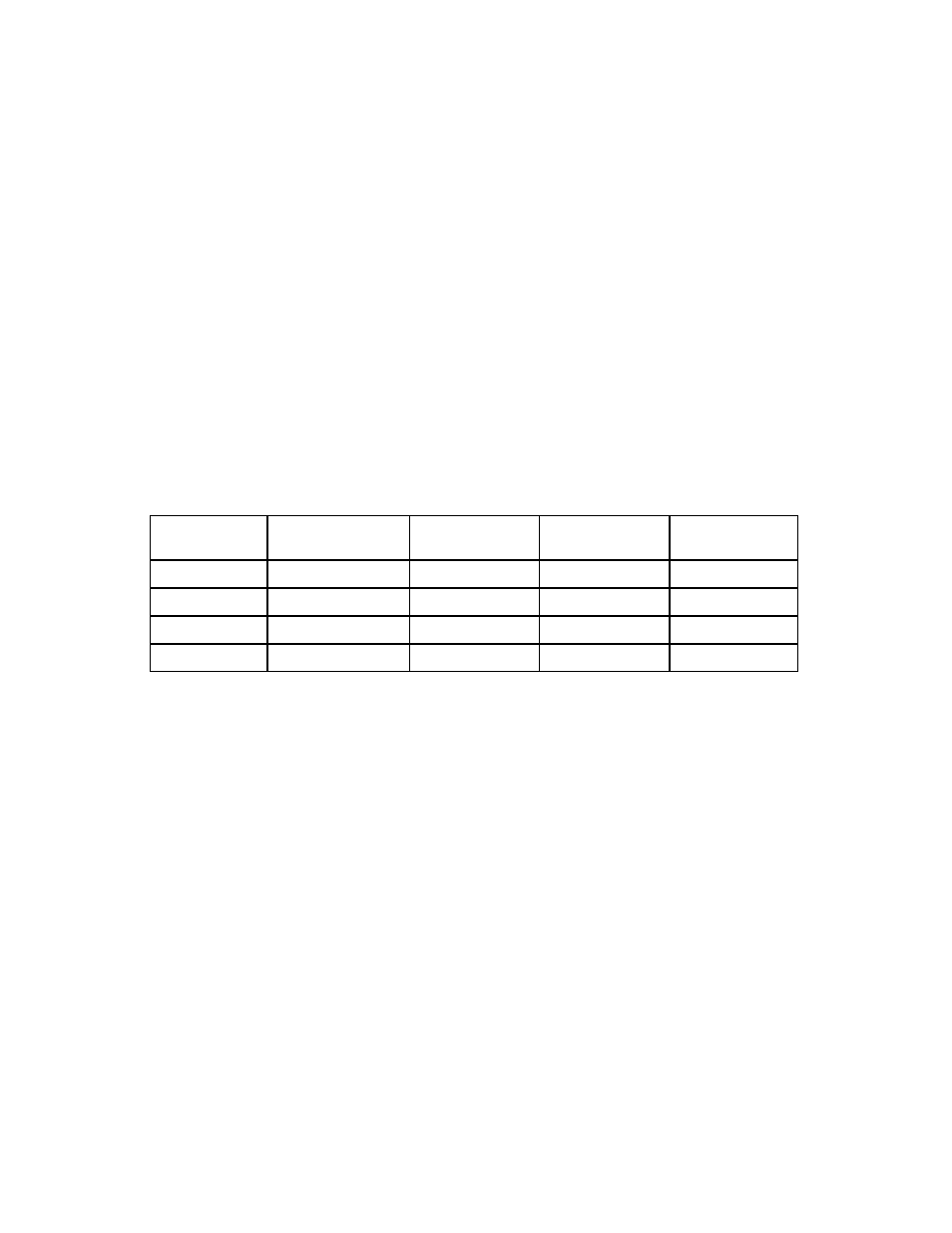

TABLE 3 – SUMMARY OF CONTROL OPERATION

Quadrant

Type of

Operation

Motor Rotation

Direction

Motor Torque

Direction

Applied Load

Direction

I

Motoring

CW

CW

CCW

II

Regeneration

CCW

CW

CCW

III

Motoring

CCW

CCW

CW

IV

Regeneration

CW

CCW

CW

B. Torque Control Mode – When Jumper J7 is set to “TRQ” position, the KBRG-255 will vary

motor torque. The KBRG-255 has been redesigned and now contains two (2) types of

torque characteristics which are selectable with jumper J8. Speed/Linear Torque (S/LT)

and Non Linear Torque (NLT). In the “S/LT” position (factory setting), both output torque

and motor speed vary linearly as a function of the input signal. The “S/LT” type of torque

is most suitable for take up and pay out winders where the speed and torque requirements

vary as the winder roll diameter changes. The “S/LT” torque characteristics are shown in

fig. 2A, p. 5.

In the “NLT” position, only torque (not speed) is varied by the input signal. The motor

output torque remains constant over the motor’s full speed range unless the load is less

than the set torque. If the load torque decreases below the set torque, the motor will rapidly

increase to full speed. This type of torque control is applicable to processes where the

torque must remain constant over a wide motor speed range. The “NLT” torque

characteristics are shown in fig. 2B, p. 6.

Because the KBRG-255 is a regenerative control, torque will be applied in both forward and

reverse directions. The maximum torque can be set with the FWD CL and REV CL

trimpots, and by using the FWD ACCEL and REV ACCEL trimpots, the rate of change of

torque can be made more or less gradual. The maximum speed trimpot can be used to set

the maximum motor speed under a no load condition.