KB Electronics KBRG-255 User Manual

Page 14

10

FIG. 7E – TACH-GENERATOR

CONNECTION

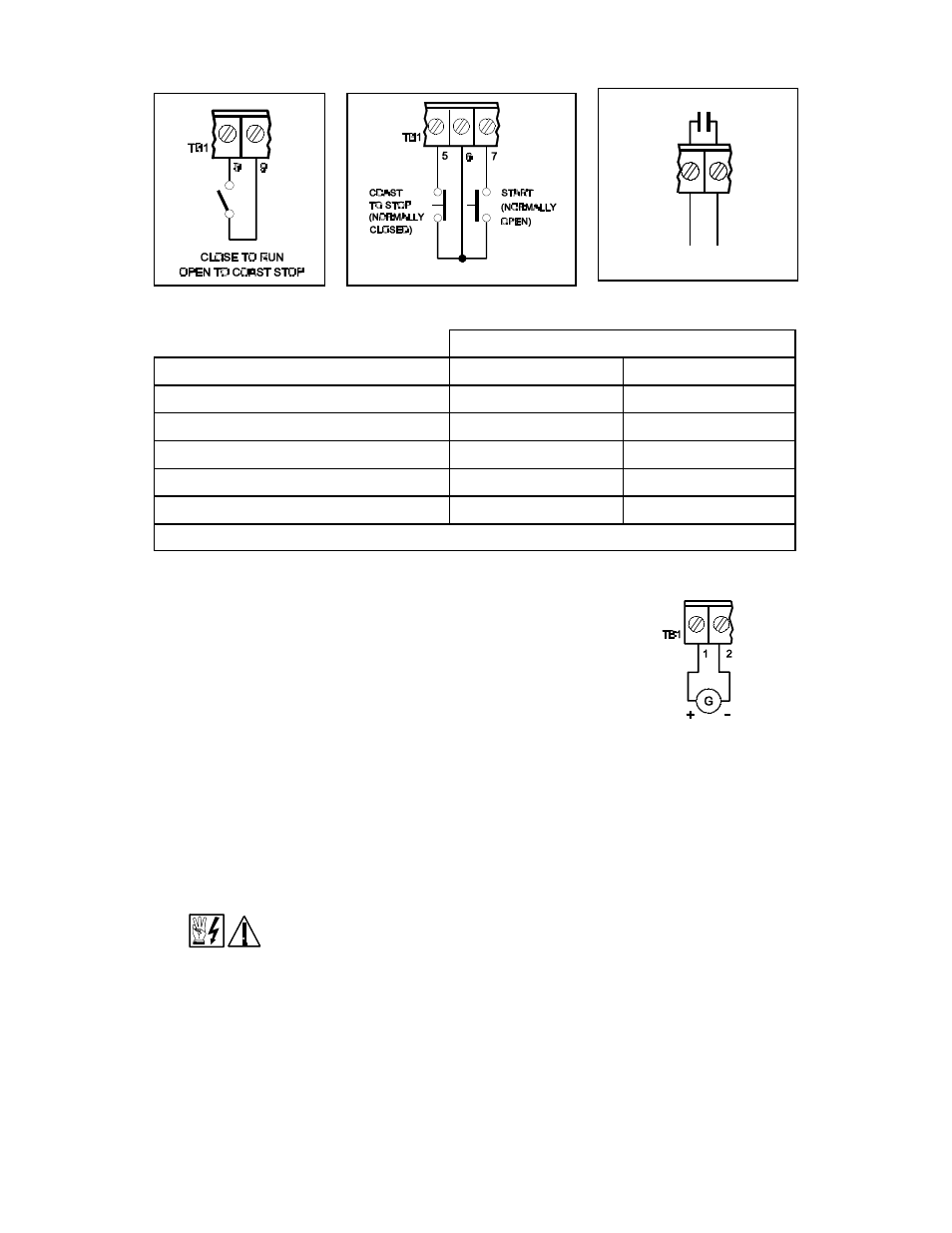

FIG. 7B – ENABLE

FIG. 7C – START/STOP CIRCUIT

4

3

RY1

CONTACTS

ALARM

TB1

FIG. 7D – ALARM CONTACTS

TABLE 6 – CONTROL STATE vs RELAY CONTACT STATE

Relay Contact State

Description of Control State

Using Start / Stop

Start / Stop Bypassed

No power to control

O

O

Power applied

O

X

Control in Stop mode

O

NA

Control is started with Start button

X

NA

Control has “Timed Out” in TCL

O

NA

O – Open, X – Closed, NA – Not Applicable

J.

Tach-generator Input – Terminals "1" and "2" are used

to connect a DC tach-generator and should be used only

when control is in Tach-generator Feedback mode (J5 is

in "TFB" position). Connect the positive (+) tach lead to terminal

"1" and the negative (-) tach lead to terminal "2." Note: The tach-

generator polarity must be phased so that the tach voltage is positive

(+) on terminal "1" when the voltage on terminal "12" is positive (+).

If the tach-generator is wired backwards, the control will run at full

speed only.

VI.

FUSING.

The logic control board contains a low amperage fuse (.150 amp Littelfuse 3AG normal blo or

equivalent) which protects the control transformer and other components against catastrophic

failure. Under normal circumstances, this fuse should never blow. (See fig. 1, p. 3, for

location.)

The KBRG-255 does not contain AC line or armature fusing. It is recommended that a 40

Amp fuse or circuit breaker be installed on each AC line conductor not at ground potential.

Do not fuse ground or neutral wires.

VII. OPERATION.

WARNING! Read Safety Warning on page 2 before attempting to operate or

severe injury or death can result.

After the KBRG-255 has been set up and the drive has been properly wired, the startup

procedure can begin. Before initially starting, be sure main speed pot is in minimum position.

(Set main speed pot to full CCW position if wired for unidirectional operation and to center

position if wired for bidirectional control. (See fig. 6, p. 9.)

Start control by applying AC power. Enable circuit must be closed for control to start (jumper

terminals "8" and "9"). If wired for start/stop operation, press start switch. If not wired for

start/stop, terminals "5" and "7" must be jumpered. Rotate main speed potentiometer to control

motor speed.