HTP CG300N65 User Manual

Page 13

13

LP-436 REV. 3.21.14

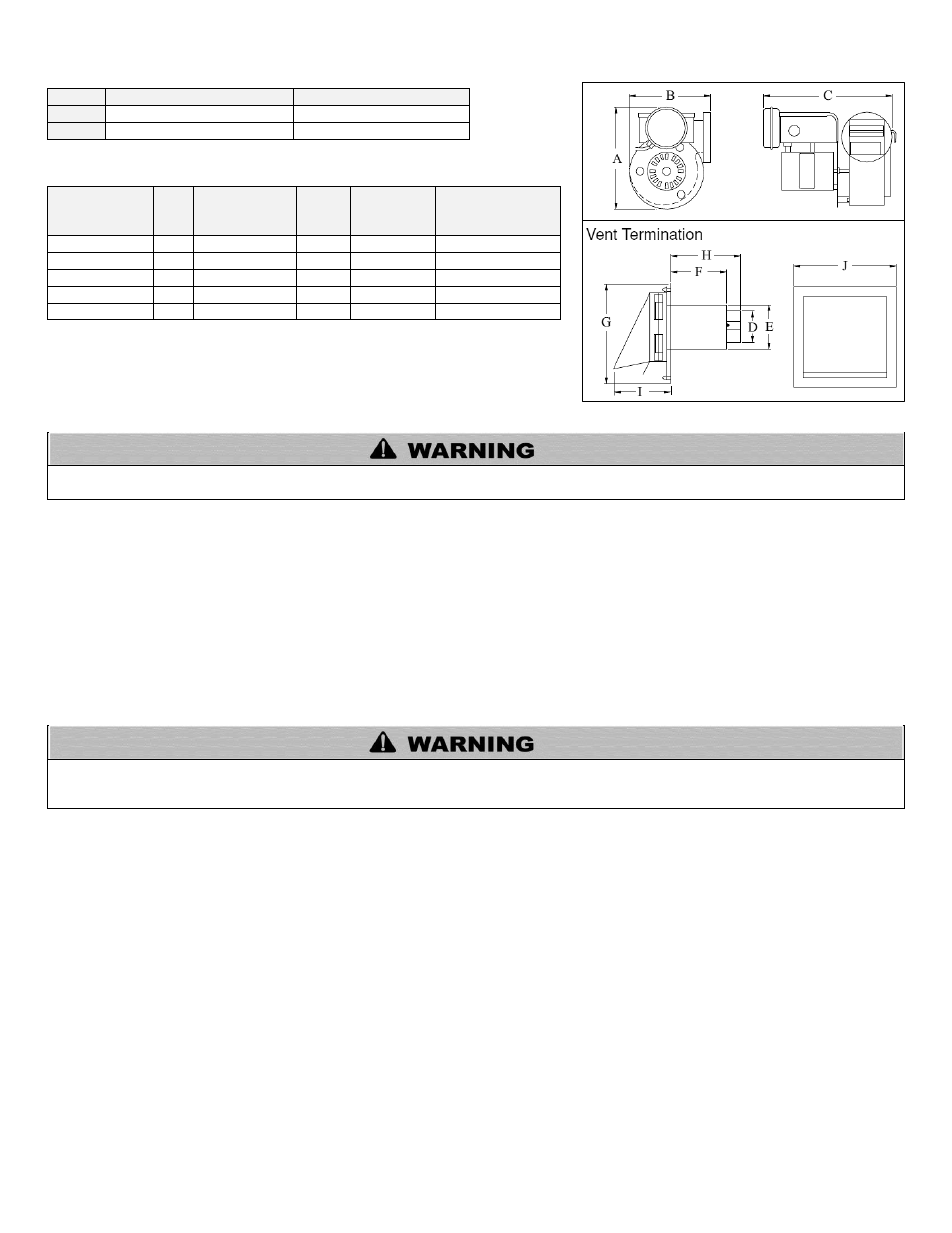

Power Venter

Vent Termination

Kit #1

Part # 6060-200

Part # 6060-202

Kit #2

Part # 6060-201

Part # 6060-203

Table 4

– Power Venter and Vent Termination Part Numbers

MODEL

KIT

DRAFT

HOOD

OUTLET

VENT

SIZE

VENT

ADAPTER

VENT

REDUCER

LOCATION

CG125N73

1

5”

4”

5”-4”

1

CG150N73

2

6”

6”

Not Req.

-

CG199N73(X)

2

6”

6”

Not Req.

-

CG250N65

2

7”

6”

7”-6”

1

CG300N65

2

8”

6”

8”-6”

1

Table 5

– Vent Sizing, By Model Number

NOTE: Vent Pipe is Not Included

When the installation is complete, visually inspect the venting system to make sure that all joints are properly connected and all

instructions have been followed. Failure to properly install the venting system can result in property damage, personal injury, or death.

Water Piping

Refer to Figure 10 for a typical installation. Use of this layout should provide a trouble-free installation for the life of the water heater.

Before making the plumbing connections, locate the COLD water inlet and the HOT

water outlet. These fittings are both 1 ½” NPT male

thread. Install a shut-off valve close to the water heater in the cold water line. It is recommended that unions be installed in the cold and

hot water lines so that the water heater can be easily disconnected if service is required.

NOTE: It is recommended to use dielectric unions when connecting to the water heater.

When assembling the hot and cold piping, use food grade pipe joint compound and ensure all fittings are tight. It is imperative that open

flame is not applied to the inlet and outlet fittings, as heat will damage or destroy the plastic lined fittings. This will result in premature

failure of the fittings, which is not covered by warranty.

Temperature and Pressure Relief Valve

DO NOT plug the temperature and pressure relief valve or its discharge line. DO NOT remove the relief valve. Make sure the relief

valve is properly sized for the water heater. If the relief valve continuously discharges water, call a qualified service technician to correct

the problem. Failure to follow these instructions can result in property damage, personal injury, or death.

To protect from excessive pressure and/or temperature, the manufacturer has installed a temperature and pressure relief valve that

meets the requirements of the Standard for Relief Valves and Automatic Gas Shut-Off Devices for Hot Water Supply Systems, ANSI

Z21.22 in the United States, and CSA 4.4 in Canada. This relief valve has a maximum set pressure that does not exceed the

hydrostatic working pressure of the water heater (150 psi = 1,035 kPa) and a BTU/H rating equal to or greater than the input rating, as

shown on the water heater rating plate. It should never be plugged or removed from the opening marked for it on the water heater.

If this relief valve should need to be replaced, use only a new temperature and pressure relief valve. Never install an old or existing

relief valve, as it may be damaged or inadequate for the working requirements of the new water heater. This new relief valve must meet

all local codes, or, at minimum, the requirements listed above. Never install any other type of valve between the relief valve and the

water heater.

A discharge line must be installed into the relief valve. The discharge line:

Must not be smaller than the outlet pipe size of the relief valve.

Must not terminate less than 6” (15.2 cm) and not more than 12” (30.5 cm) above a floor drain.

Must not be restricted in any way. Do not thread, cap, or in any way restrict the end of this outlet.

Must be of a material capable of withstanding 193

o

F (90

o

C) without distortion.

Must be installed to allow complete drainage of the relief valve and discharge line.

Must terminate at an adequate free-flowing drain.

Figure 9

– Power Venter and Vent Termination