Harrington Hoists and Cranes AHM Hoist User Manual

Page 20

20

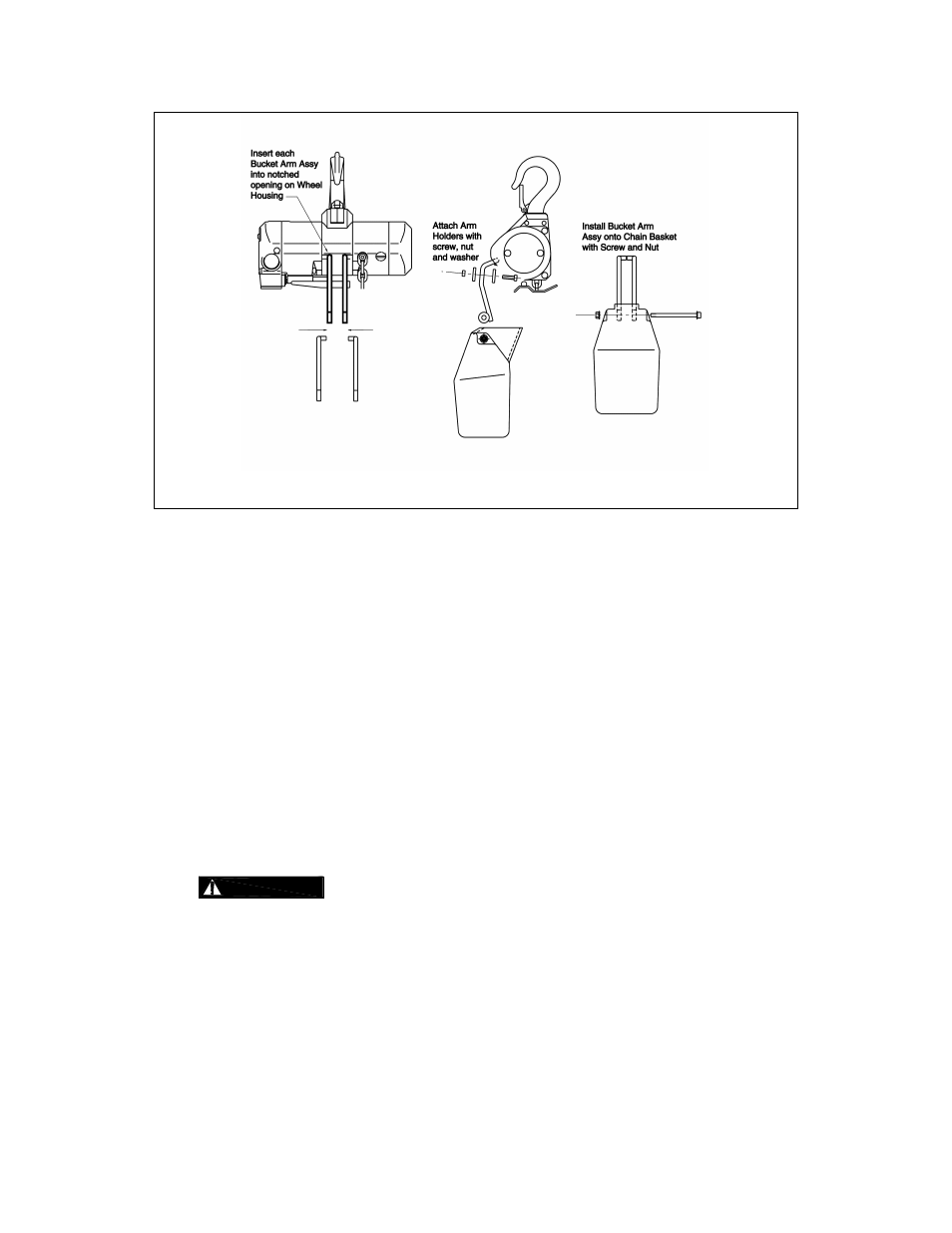

Figure 3-7 Chain Container Installation

3.11 Non-Stationary Application

3.11.1 For applications such as rental fleets or construction sites where the hoist is moved from place-to-place,

a filter and lubricator are still required. Consult factory for recommended methods.

3.11.2 Connections and fittings must be kept clean and care taken to prevent dirt, debris and moisture from

entering the hoist.

3.11.3 Recommended practice for removing the hoist from an installation:

1) Run the hoist briefly with well lubricated air

2) Shut off the air supply to the hoist, bleed off any pressure in the system then disconnect the air

supply line.

3) Inject a small quantity (approximately 20 drops) of tubine oil (see Section 6.0) into the hoist’s inlet

port

4) Plug the inlet port

3.12 Manipulator Right or Left Hand Operation

3.12.1 Follow instructions below to configure for right or left-hand operation. Refer to Figure 3-8.

1)

HAZARDOUS AIR PRESSURE IS PRESENT IN THE HOIST, IN THE

SUPPLY OF COMPRESSED AIR TO THE HOIST, AND IN THE CONNECTIONS BETWEEN

COMPONENTS. Shut off the air supply and stop the airflow completely. Bleed off any pressure in

the system. Lock out and tag out in accordance with ANSI Z244.1 “Personnel Protection -

Lockout/Tagout of Energy Sources”.

2) Remove the 6 Button Head Screws located on the back side of the Manipulator control then

remove the Throttle Valve Complete.

3) Make sure the 8 O-Rings and 2 Spring Pins are correctly positioned, then rotate the Throttle Valve

Complete 180 degrees and re-install.

4) Re-install and tighten the 6 Button Head Screws

5) Re-connect or turn on the air supply and check for leaks and proper operation.