Rivers Edge RE627 Oasis User Manual

Page 30

Check for parts online at

www.huntriversedge.com or call 800-450-EDGE (3343) M-F 8-5

Check for parts online at

www.huntriversedge.com or call 800-450-EDGE (3343) M-F 8-5

30

Operator's Manual

Rivers Edge® One-Man Ladder Stands

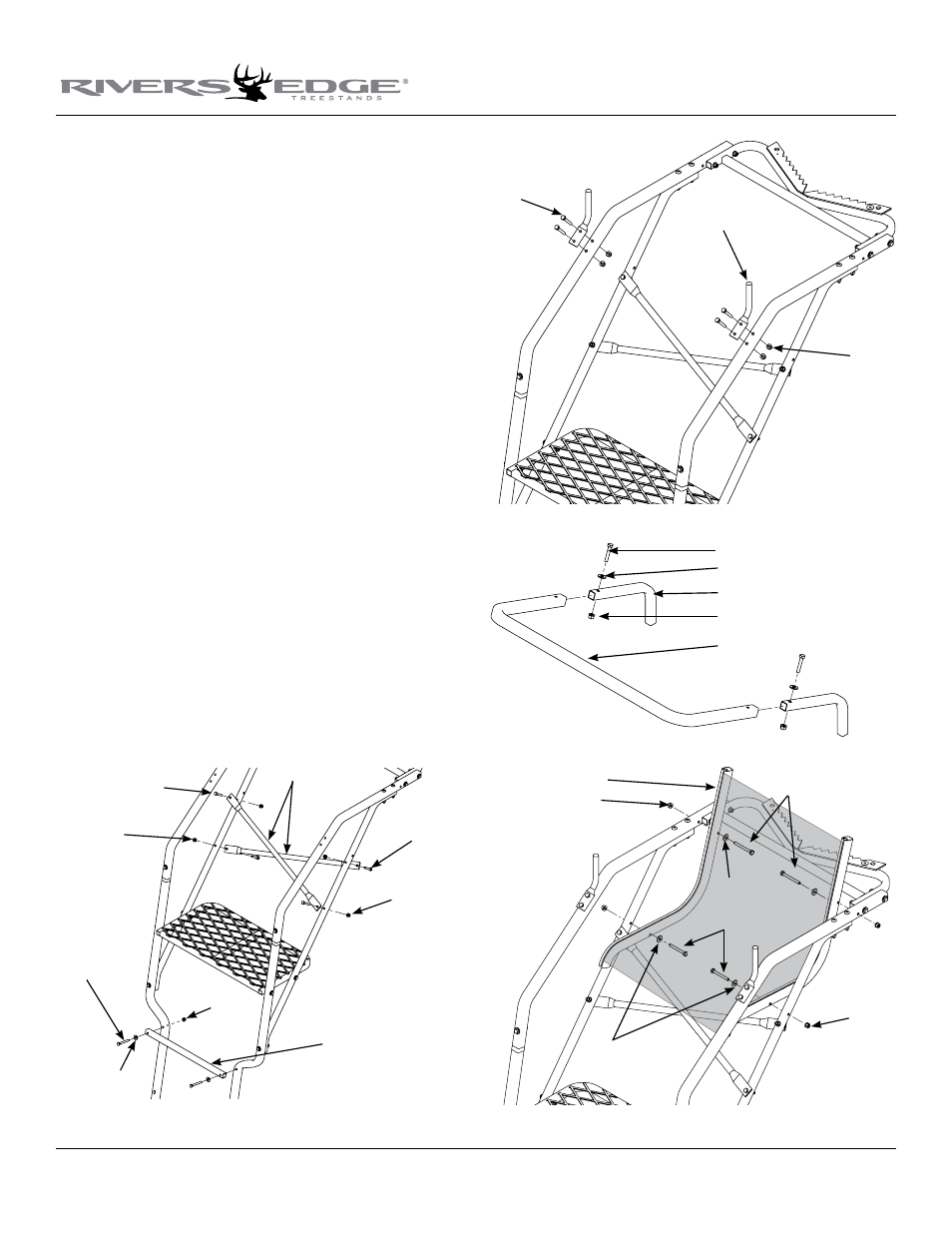

5. Attach the round tube, double flat braces (10377) to the upper lad-

der support tubes using (4) provided 1/4-20 x 1-1/2” bolts and lock-

nuts. sEE fIGuRE 4. One double flat brace should be positioned on

each side of the upper ladder support tubes for clearance purposes.

6. Attach the bolt-on step (410034) to the front side of flared rails us-

ing (2) provided 1/4-20 x 2-1/4” bolts, locknuts and steel washers.

sEE fIGuRE 4.

7. Attach the shooting rail posts (10393) to the main side rails using

(4) provided 1/4-20 x 1-3/4” bolts and locknuts. sEE fIGuRE 5.

8. Insert the shooting rail J-pipes (410113) into the shooting rail rim

(10394). Secure together using (2) provided 1/4-20 x 1-1/2” bolts,

locknuts and steel washers. sEE fIGuRE 6. You must now tighten

all nut and bolt assemblies. Be sure not to over tighten or crush

tubing when tightening!

9. Attach the factory assembled mesh seat with seat rails (10549) to

the previously assembled upper ladder stand assembly.

a. Using (2) provided 1/4-20 x 2-1/2” bolts, locknuts and steel washers,

attach the upper portion of each seat rail to the main side rails.

sEE fIGuRE 7. It is important to have the bolt head on the seat rail

side and the locknut on the main side rail side for ease of assembly.

fINGER TIGhTEN ThEsE TWO BOlTs ONlY AT ThIs TIME.

b. Using (2) provided 1/4-20 x 2-1/4” bolts, locknuts and steel

washers, attach the lower portion of each seat rail to the upper

ladder support tubes. sEE fIGuRE 7. It is important to have the

bolt head on the seat rail side and the locknut on the upper

ladder support tube side for ease of assembly.

c. Alternately tighten all four nut/bolt assemblies from steps 9a

and 9b. The spanned mesh seat will become tighter as you tighten

each nut/bolt assembly. Tighten until all steel tubular components

are tight to each other, locking feature of nuts are fully engaged

by bolt threads and spanned mesh seat is taut. Be sure not to

over tighten or crush tubing when tightening!

Figure 4

Figure 5

Figure 6

Figure 7

1/4-20 x 1-1/2"

bolts

1/4-20 x 2-1/4"

bolts

locknuts

1/4-20 x 1-1/2"

bolts

locknuts

locknuts

steel washers

locknuts

1/4-20 x 1-3/4"

bolts

shooting rail posts

1/4-20 x 1-1/2" bolts

locknuts

shooting rail J -pipes

shooting rail rim

steel washer

locknuts

1/4-20 x 2-1/2" bolts

steel washers

seat rails

1/4-20 x 2-1/4" bolts

steel washers

locknuts

bolt-on step

double flat braces