Archive, Rf 1 fiber optic - safety – Ransburg RF1 FiberOptic Meter 77786-XX, A11516-XX User Manual

Page 8

FM-00-02.5

4

4

4

4

4

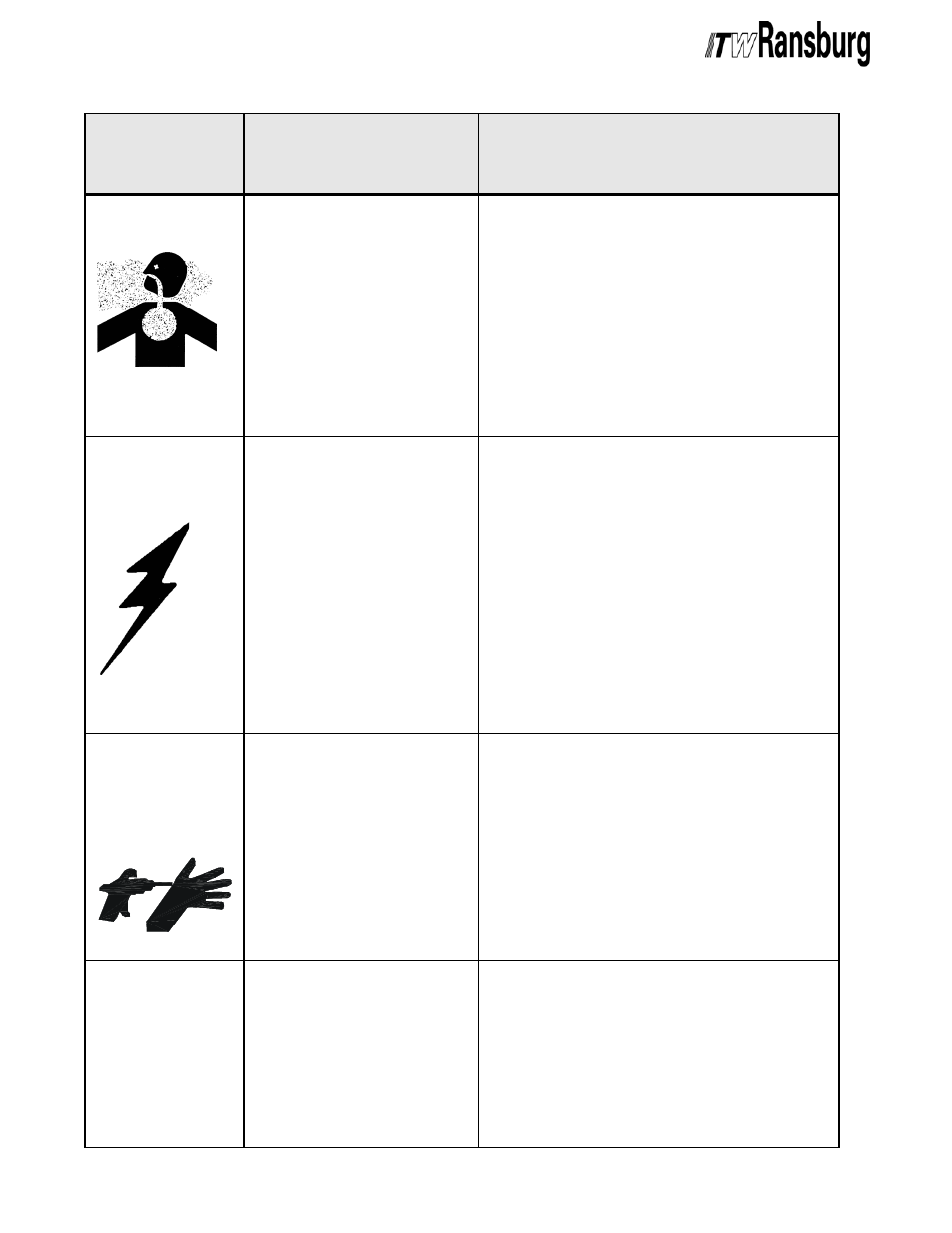

RF 1 Fiber Optic - Safety

T o x i c

T o x i c

T o x i c

T o x i c

T o x i c

Substances

Substances

Substances

Substances

Substances

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be NIOSH

approved.

A R E A

A R E A

A R E A

A R E A

A R E A

Tells where hazards

may occur.

H A Z A R D

H A Z A R D

H A Z A R D

H A Z A R D

H A Z A R D

Tells what the hazard is.

S A F E G U A R D S

S A F E G U A R D S

S A F E G U A R D S

S A F E G U A R D S

S A F E G U A R D S

Tells how to avoid the hazard.

Spray Area /

Spray Area /

Spray Area /

Spray Area /

Spray Area /

High Voltage

High Voltage

High Voltage

High Voltage

High Voltage

Equipment

Equipment

Equipment

Equipment

Equipment

There is a high voltage device that

can induce an electrical charge on

ungrounded objects which is

capable of igniting coating

materials.

Inadequate grounding will cause a

spark hazard. A spark can ignite

many coating materials and cause

a fire or explosion.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Any person working in the spray area must be

grounded.

Unless specifically approved for use in hazardous

locations, the power supply and other electrical

control equipment must not be used in Class 1,

Division 1 or 2 locations.

Personnel

Personnel

Personnel

Personnel

Personnel

Safety/ Fluid

Safety/ Fluid

Safety/ Fluid

Safety/ Fluid

Safety/ Fluid

Injection Hazard

Injection Hazard

Injection Hazard

Injection Hazard

Injection Hazard

(High Pressure

(High Pressure

(High Pressure

(High Pressure

(High Pressure

Equipment)

Equipment)

Equipment)

Equipment)

Equipment)

Fluid Injection Injury

Never let any part of the body come in direct contact

with the fluid stream exiting from the nozzle. If fluid

leaks occur in the gun or in the fluid delivery

components, depressurize fluid system before

servicing.

Never aim the applicator at any part of the body under

any circumstances.

If you are injured by high pressure fluid injection,

immediate medical treatment must be sought.

Intended Use

Intended Use

Intended Use

Intended Use

Intended Use

(Waterborne

(Waterborne

(Waterborne

(Waterborne

(Waterborne

Only)

Only)

Only)

Only)

Only)

Using coating materials and/or

cleaning and flushing solvents

which have flash points below

100

°F (37.8°C) may cause a fire

hazard.

This system is intended for use with waterborne

coating formulations only.

Waterborne, waterbase and water reducible coatings

are considered the same. Although they may not be

highly flammable, their residues are considered

combustible.

ARCHIVE