General Pump Pump Installation and Service Manual User Manual

Page 7

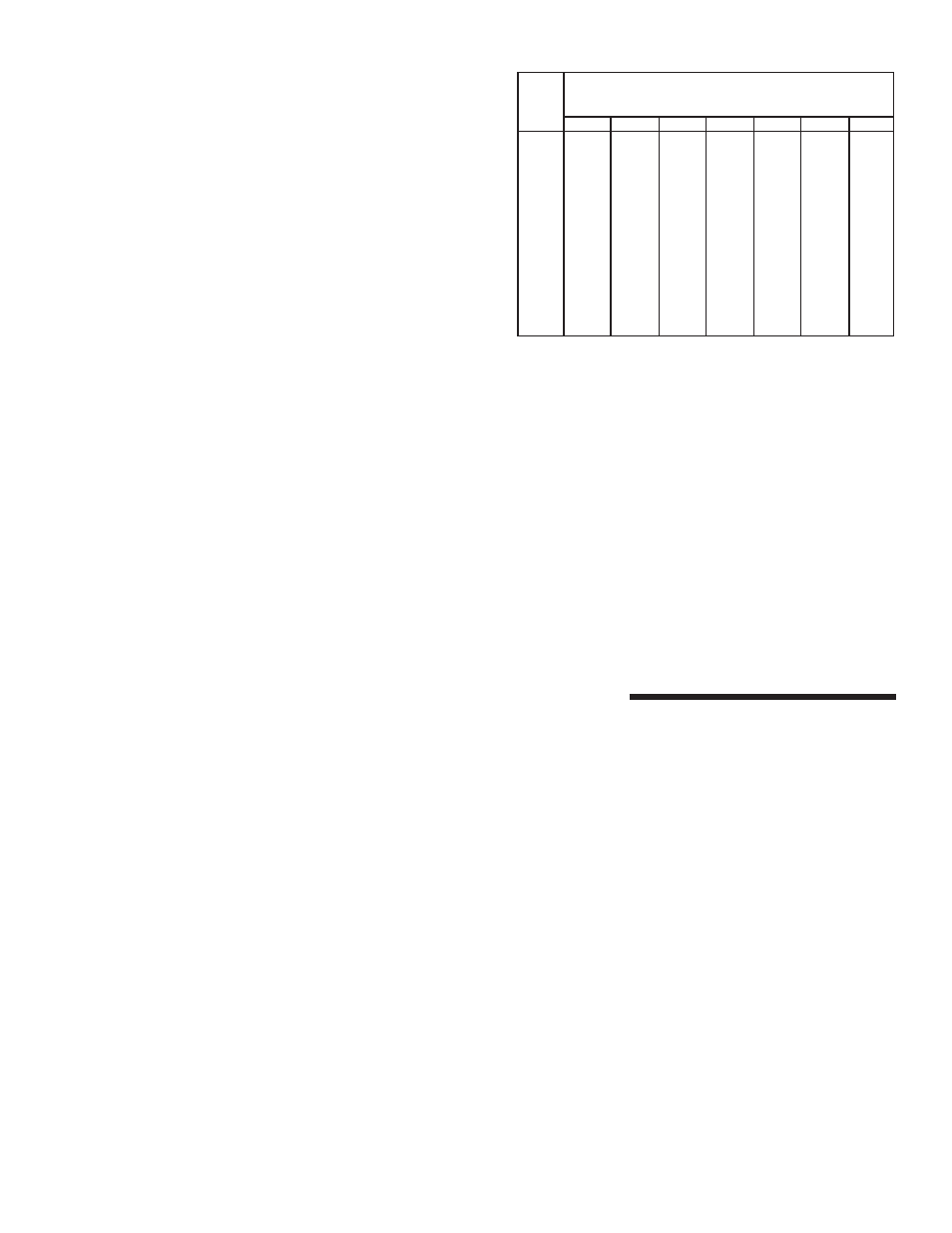

WATER

FLOW

GAL/MIN

PRESSURE DROP IN PSI PER 100 FT OF HOSE

WITH TYPICAL WATER FLOW RATES

(HOSE INSIDE DIAMETERS, INCHES)

1/4

5/16

3/8

1/2

5/8

3/4

1”

0.5

16

5

2

1

54

20

7

2

2

180

60

25

6

2

3

380

120

50

13

4

2

4

220

90

24

7

3

5

320

130

34

10

4

6

220

52

16

7

1

8

300

80

25

10

2

10

120

38

14

3

15

250

80

30

7

20

121

50

12

25

200

76

19

40

410

162

42

60

370

93

servicing unloader valves. The valve should be mounted

as close to the pump outlet as possible; do not use any

hose between the pump and the unloader.

Pressure Relief Valve - A safety device which when

installed and set-up according to the manufacturer’s

specifications will open and dump to atmosphere a

quantity of water if the system becomes overpressurized

due to a failure of system components.

Pulsation Dampener - Pulsation Dampeners are

installed in systems either to smooth out the pulsations

caused by the pump itself or to absorb pressure spikes

when the gun is shut off. A duplex pump may require a

pulsation dampener because of the pulsation not

experienced with a triplex pump. When there are long

runs of pipe, a pulsation dampener may be required to

soften the hammer effect when a gun is shut off.

Pressure Gauge - Allows the equipment operator to

monitor the system for peak performance. A worn spray

tip will be evident with a decrease in system pressure.

High pressure may indicate a partially plugged spray tip

or other restriction, or a defect in the unloader valve.

Important factors in gauge selection:

• Liquid filled - to absorb the pressure fluctuations

in the system.

• Restriction orifice installed to avoid damage from

pressure “spikes”.

• Select a gauge so that normal system operating

pressure is in the middle of the gauge’s range.

Downstream Injector - Introduces a cleaning chemical

into the water stream after or downstream of the pump.

Care must be taken to size the injector to the system

volume or GPM. Check with manufacturer’s literature.

Too small of an injector causes a large pressure drop

across the injector and injects a very high concentration

of chemical. Too large of an injector will not draw any

chemical. Downstream injectors require low pressure,

generally about 200 PSI, to activate the chemical flow.

A double nozzle holder, rollover nozzle, and a double

lance are a few accessories that allow mounting a low

pressure spray tip, as well as the standard high pressure

spray tip. An adjustable nozzle allows a large orifice to

be opened around the high pressure spray tip.

High Pressure Hose - A required component of your

system. Be sure that the hose that you select to use is

compatible with all chemicals that will be introduced

into the system, is rated at least 50% greater

than the system operating pressure, has

good quality Permanite couplings on each end (do

not use hose clamps), and is as short as

possible to avoid pressure accumulation when

releasing trigger, and to minimize operating

pressure loss in hose.

7

If quick disconnect couplings are used on the ends of

the high pressure hose, be sure that they are of the

“straight through” design. Air type quick couplers with

internal “shut-offs” are not acceptable because

pylsations in the water flow will destroy the moving parts

and lodge them in the gun and/or spray tip.

Spray Gun - Must be selected to withstand pressure,

volume, temperature and chemicals in the system. Guns

must be durable to withstand the kind of abuse typical in

pressure wash applications. Consider comfort to reduce

operator fatigue. Ease if servicability is also important.

There are many types and styles of guns available. Be

sure to “shop around” and select one that most closely

fits your needs.

INSTALLING YOUR

COMPONENTS

Refer to manufacturer’s printed literature and install

all components according to manufacturer’s

recommendations to avoid serious bodily injury or

property damage and to insure proper system

operation.

All plumbing and component parts must be of the same

size or larger than is on the inlet and outlet of your pump.

The thread sizes are a guide to the required

sizes of plumbing for proper water flow both in and out

of the pump.

All plumbing and component parts must have an

operating pressure rating of at least 50% above the

maximum rated output pressure of the pump, and should

have an actual burst pressure of 3-5 times the normal

system working pressure.

HOSE FRICTION LOSS