Servicing your pump – General Pump Pump Installation and Service Manual User Manual

Page 10

SERVICING YOUR

PUMP

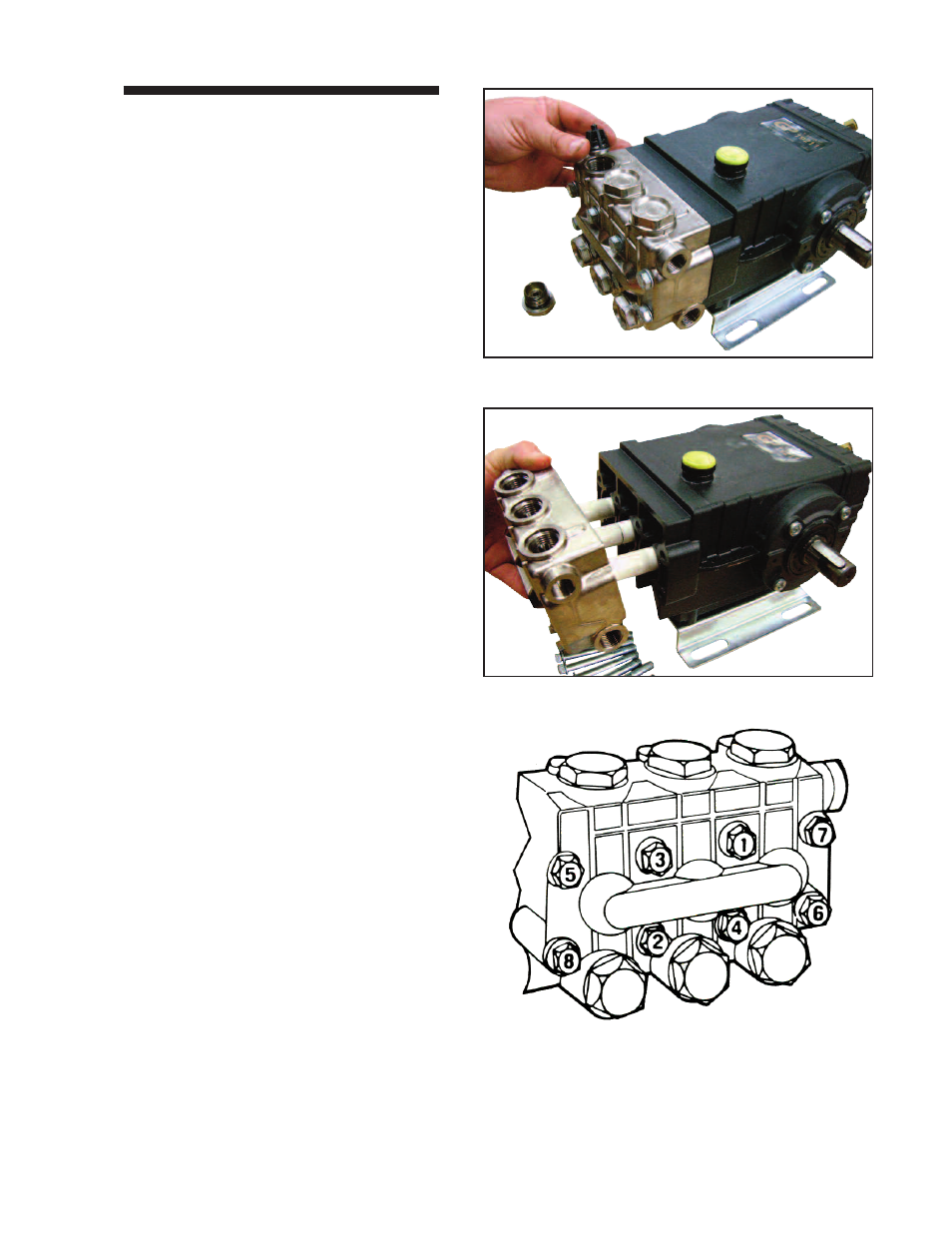

VALVE ASSEMBLIES (Figure 1)

1. All inlet and discharge valves can be serviced

without disrupting the inlet or discharge

plumbing. The inlet and discharge valves

are identical in all models.

2. To service any valve, remove valve cap and

extract valve assembly.

3. Examine o-rings and replace if there is any

evidence of cuts abrasions or distortion.

4. Remove valve assembly (retainer, spring valve,

valve seat) from valve cavity.

5. Remove o-ring from valve cavity.

6. Only one valve kit is necessary to repair all the

valves in the pump. The kit included new o-rings,

valve seat, poppet, spring and retainer, all

pre-assembled.

7. Install new o-rings in valve cavity.

8. Insert assembly into valve cavity.

9. Replace valve cap and torque to specifications.

REMOVING MANIFOLD HEAD (Figure 2)

1. Remove the fasteners retaining the head.

2. Separate head from crankcase. NOTE: It may be

necessary to tap head lightly with rawhide

mallet to loosen. CAUTION: When sliding head

from crankcase use caution not to damage plungers.

3. The V-packing assemblies may come off with

the head. At this point, examine plungers.

Plunger surfaces should be smooth and free

from scoring or pitting; if not, replace.

4. Reinstall manifold head and torque to

specifications per sequence described below.

TORQUE SEQUENCE FOR TIGHTENING HEAD

(Figure 4)

Install all head bolts fingertight. Torque to 10 foot pounds

in sequence as shown, then retorque to specifications,

again in sequence shown.

10

1

2

4