Drive system – General Pump Pump Installation and Service Manual User Manual

Page 5

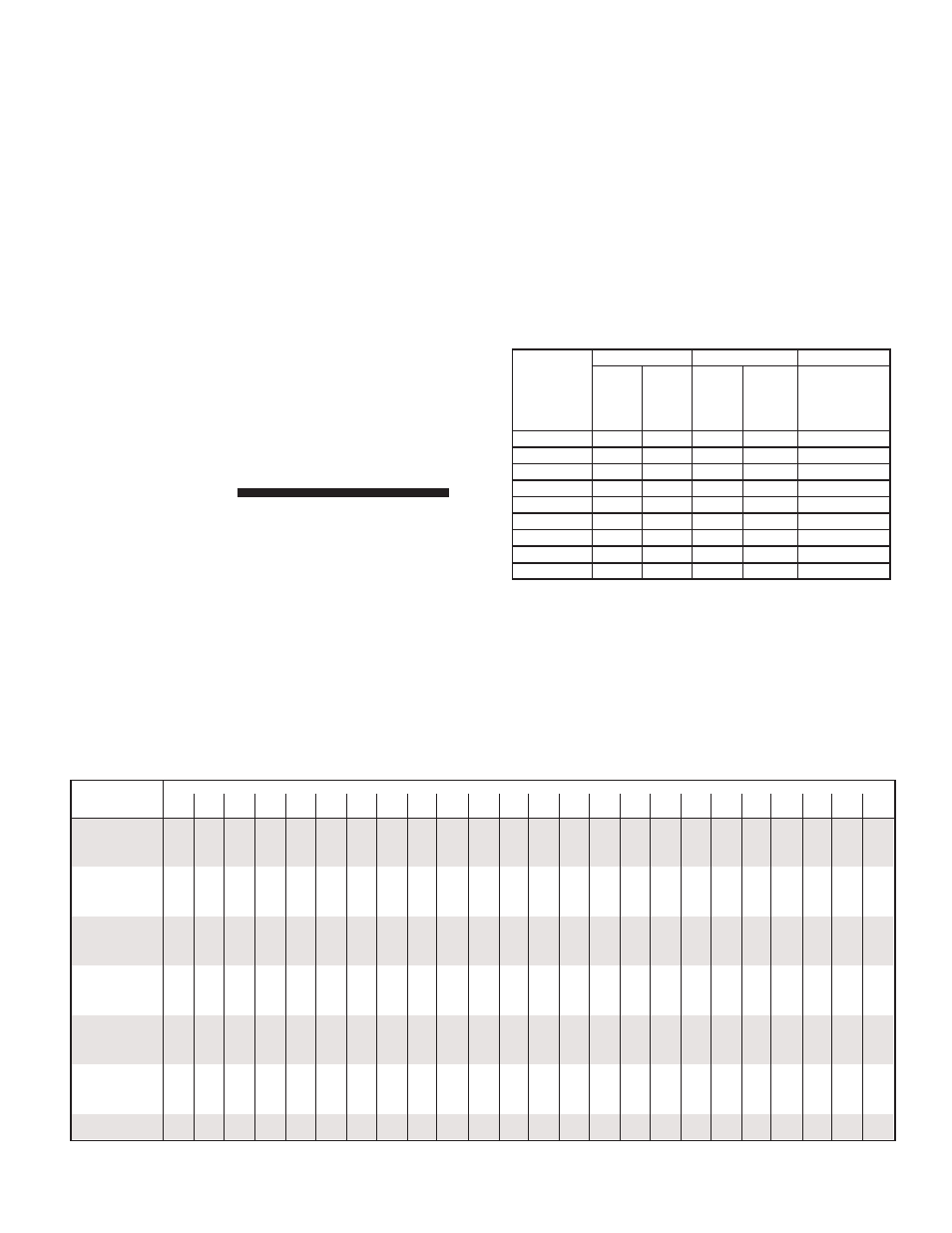

Pump Pulley

Outside Diameter

(inches)

MOTOR PULLEY OUTSIDE DIAMETER (inches)

2-1/2 2-3/4

3

3-1/4 3-1/2 3-3/4

4

4-1/4 4-1/2 4-3/4

5

5-1/4 5-1/2 5-3/4

6

6-1/2

7

8

9

10

11

12

13

14

2-1/2

1725

2-1/4

1574 1725

3

1431 1590 1725

3-1/4

1310 1460 1604 1725

3-1/2

1210 1346 1480 1615 1725

3-3/4

1125 1250 1375 1500 1625 1725

4

1050 1168 1283 1400 1518 1634 1725

4-1/4

985 1094 1201 1311 1420 1530 1640 1725

4-1/2

926 1030 1131 1235 1339 1440 1543 1650 1725

4-3/4

876

974 1070 1168 1285 1362 1460 1558 1652 1725

5

830

922 1013 1105 1198 1290 1382 1473 1568 1660 1725

5-1/4

788

875

963 1050 1137 1225 1312 1400 1487 1575 1662 1725

5-1/2

750

834

917 1000 1082 1167 1250 1333 1417 1500 1581 1646 1725

5-3/4

715

795

875

955 1032 1113 1192 1270 1350 1430 1510 1575 1650 1725

6

685

760

937

913

990 1065 1140 1217 1290 1370 1450 1509 1581 1653 1725

6-1/2

630

700

771

840

910

980 1050 1120 1190 1260 1330 1393 1460 1526 1592 1725

7

584

648

713

778

843

907

973 1039 1102 1168 1231 1294 1355 1417 1500 1602 1725

8

507

564

620

676

734

789

845

902

959 1016 1072 1132 1186 1240 1312 1421 1509 1725

9

450

500

550

600

650

700

750

800

850

900

950 1006 1054 1102 1166 1263 1342 1533 1725

10

405

450

495

540

585

630

675

720

765

810

855

906

949

992 1050 1137 1208 1380 1553 1725

11

366

407

448

488

530

570

610

652

692

733

774

823

863

902

954 1034 1098 1255 1411 1568 1725

12

336

373

410

446

485

522

560

596

634

671

708

755

791

827

875

947 1006 1150 1294 1438 1581 1725

13

309

343

378

412

447

480

515

549

584

618

652

697

730

763

807

875

929 1062 1194 1327 1460 1592 1725

14

286

318

350

382

414

445

477

509

540

573

605

647

678

708

750

813

863

986 1109 1232 1355 1479 1602 1725

15

267

297

326

358

386

415

445

475

505

534

564

604

633

661

700

758

805

920 1035 1150 1265 1380 1495 1610

16

250

278

306

333

361

389

416

445

473

500

528

566

593

620

656

711

755

863

970 1078 1186 1294 1402 1509`

DETERMINING SPRAY TIP SIZE

As stated earlier in this manual, the output pressure is

determined by forcing the output volume of water

through a certain size orifice or spray tip. Spray tip

size is a very important factor of proper pressure

washer performance, using a tip that is sized too

small will allow overpressurization of the pump and

components. You must know your output GPM and

your desired output PSI to properly select a spray tip

size. To use the chart on page 4, find the desired PSI,

read down the column until you find the output GPM

closest to your pump application. Read to the far left to

find the spray tip number and orifice diameter. Example:

1000 PSI at 4.0 GPM needs a number 8 spray tip.

Spray tips are available in various spray angles. It is

advisable to have different spray angle tips in the same

size for different cleaning applications. Some spray

tips or nozzles are available with an adjustable spray

angle.

DRIVE SYSTEM

There are three common methods of driving or

connecting the pump and motor/engine. Direct

drive and gear reductions drive require special

components that are matched to the pump and to the

motor.engine, as well as other technical

considerations. A belt and pulley system is the

recommended method of driving the pump because

it allows easy reduction of the motor/engine RPM

to your required pump RPM, as well as absorbing

shocks produced by both the engine and the pump.

5

PULLEY SELECTION

There are many types of belts and pulleys available,

the following is a basic guide. Manufacturer’s

representatives should be consulted concerning your

specific requirements.

From the Motor Pulley Guide (below) determine the

pulley size (A, B or C section), and number and size

(A, B or C section) of belt required. the larger in size

and/or number of belts used will increase the life

of belts. Be sure to consider space limitations of your

finished assembly.

To determine pump pulley size (based on a 1725

RPM motor), find the motor pulley size on the chart

below, follow the column down until you find your

required Pump RPM to meet your requirements, or

the next higher RPM. Follow the column to the left to

find pump pulley diameter.

To Transmit:

HORSEPOWER

“A” SECTION BELT

“B” SECTION BELT “C” SECTION BELT

1 Belt

Single

Groove

Pulley

2 Belts

Double

Groove

Pulley

1 Belt

Single

Groove

Pulley

2 Belts

Double

Groove

Pulley

1 Belt

Single

Groove

Pulley

1

2-1/2 Dia

-

-

-

-

1-1/2

3

-

-

-

-

2

3-1/4

-

-

-

-

3

3-3/4

3 Dia

4-1/2 Dia

3-1/2 Dia

-

5

5-1/4

3-1/2

5

5

-

7-1/2

-

4-1/2

66

5

-

10

-

5-1/4

8

5

8 Dia

15

-

7

10

6

9

20

-

9

-

7

10

MOTOR PULLEY GUIDE

PUMP PULLEY GUIDE (1725 RPM Motor)