Selecting remaining components – General Pump Pump Installation and Service Manual User Manual

Page 6

6

If your motor/engine will be operated at a speed

other than 1725 RPM, the pump pulley diameter can

be calculated using the following formula:

Example: Using a 1200 RPM motor, and a pump that

you want to turn at 850 RPM for your desired GPM

output, and you have chosen a 4-1/2” diameter motor

pulley.

1.412 x 4.5 = 6.39 actual pump pulley diameter.

There may not be a pulley available in the exact size as

calculated. Simply use the closest one.

BELT SELECTION

Be sure to use the same section belts (A, B or C) as the

pulleys were sized for.

Use the following formula to calculate belt length.

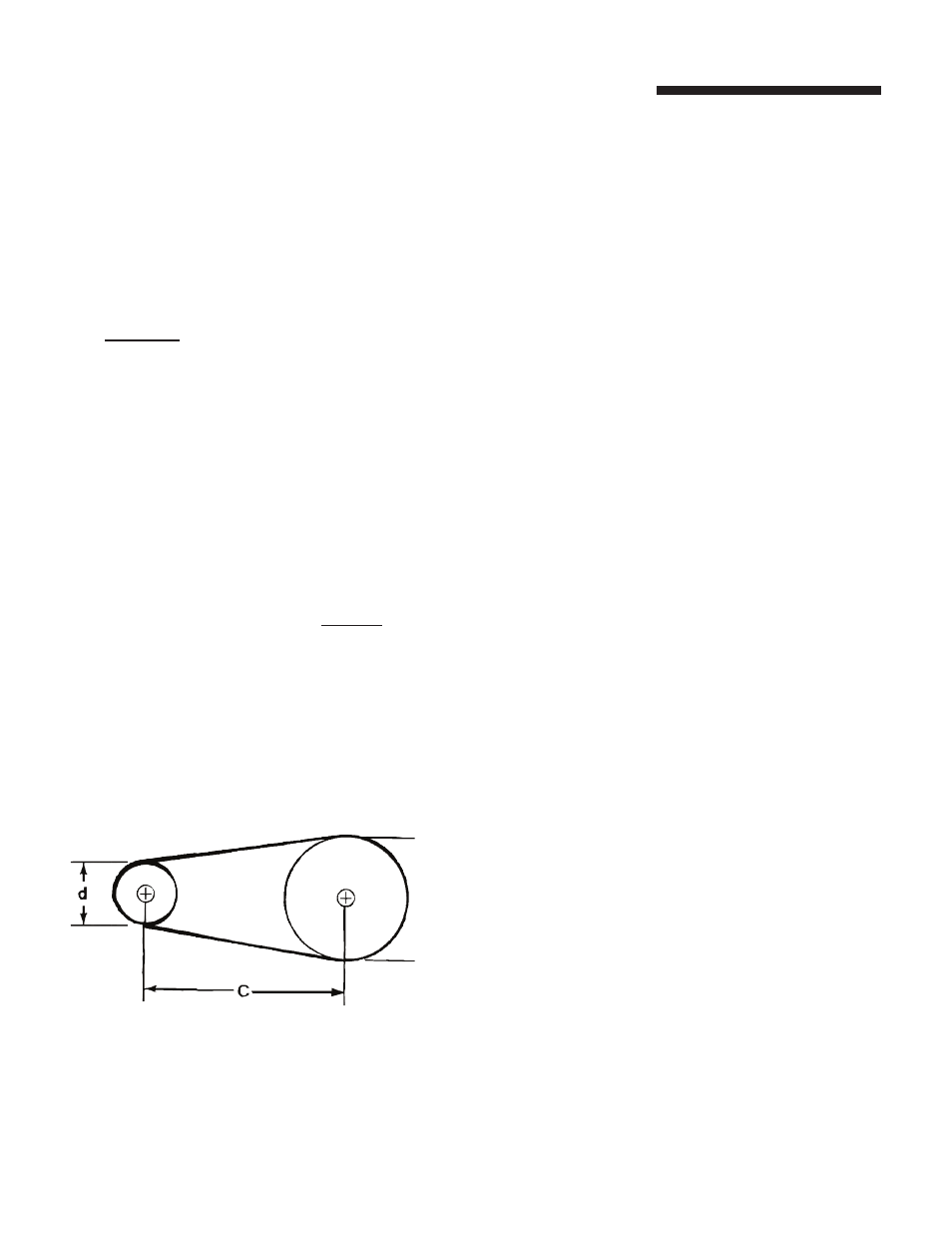

Where: L = Effective outside length of belt(s) in

inches.

C = Distance between centers of pulleys

in inches.

D = Outside diameter of pump pulley in

inches.

d = Outside diameter of motor/engine in

inches.

Always install a safety cover or guard over belt and

pulleys to avoid serious bodily injury or property

damage.

SELECTING REMAINING

COMPONENTS

UPSTREAM OR INLET SIDE COMPONENTS

Inlet Filter - A very important component to increase

system life and avoid operating problems. A 60 - 120

mesh screen filter is necessary to stop foreign matter

from entering the system and possibly holding valves

open, clogging orifices, scratching plungers, tearing

packing, and causing unnecessary wear on all

components.

By-pass Provision - As mentioned earlier in this manual,

the unloader or regulator valve by-passes or recirculates

pumped water when the gun trigger is released. A

provision must be made in the inlet plumbing (or inlet

water holding tank) to accept this flow of water without

restricion.

Thermal Relief Valve - This is a temperature sensing

valve that opens and dumps water to the atmosphere

at a predetermined temperature. Recirculating water

(through the by-pass loop) has a tendency to heat up

to temperatures that can eventually damage internal

pump parts. A thermal relief valve is an inexpensive way

to avoid costly repairs.

Upstream Injector - A device which uses the pumps

ability to draw or suck fluid to introduce a cleaning

chemical into the water stream. This type of injector is

recommended for very mild chemicals only as the entire

system (especially the pump) is exposed to the

corrosive tendencies of the cleaning chemicals.

Pressure Reducing Valve - If the water supply entering

the pump is above maximum inlet pressure rating called

out on the Pump Data Sheet. A pressure reducing valve

must be installed for proper pump operation.

Back-Flow Preventer - When using cleaning chemicals,

care must be taken to avoid these chemicals fom being

back-flushed and contaminating the city water supply.

Check your local plumbing codes. An alternative option

to a “back-flow preventer” is the use of a water holding

tank. If a holding tank is used, be sure not to exceed

the negative pressure rating of the pump.

DOWNSTREAM OR OUTLET SIDE

COMPONENTS

Unloader or Regulator Valve - As mentioned earlier,

this device is required to direct the constant flow of water

either through the spray tip when the gun is open, or by-

pass the flow back to the inlet side of the pump when the

gun is closed. Be sure to adhere to manufacturer’s re-

quirements when selecting, installing, setting-up and

RPM

Ration

X

Motor

Pulley

Diameter

X

Pump

Pulley

Diameter

1200

850

=

1.412 RPM Ratio

L = 2(c) + 1.57 (D + d) + (D - d)

2

4C