Kfm series, General pump – General Pump KFM Owner Manual User Manual

Page 8

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

Page 8

8. PORTS AND CONNECTIONS

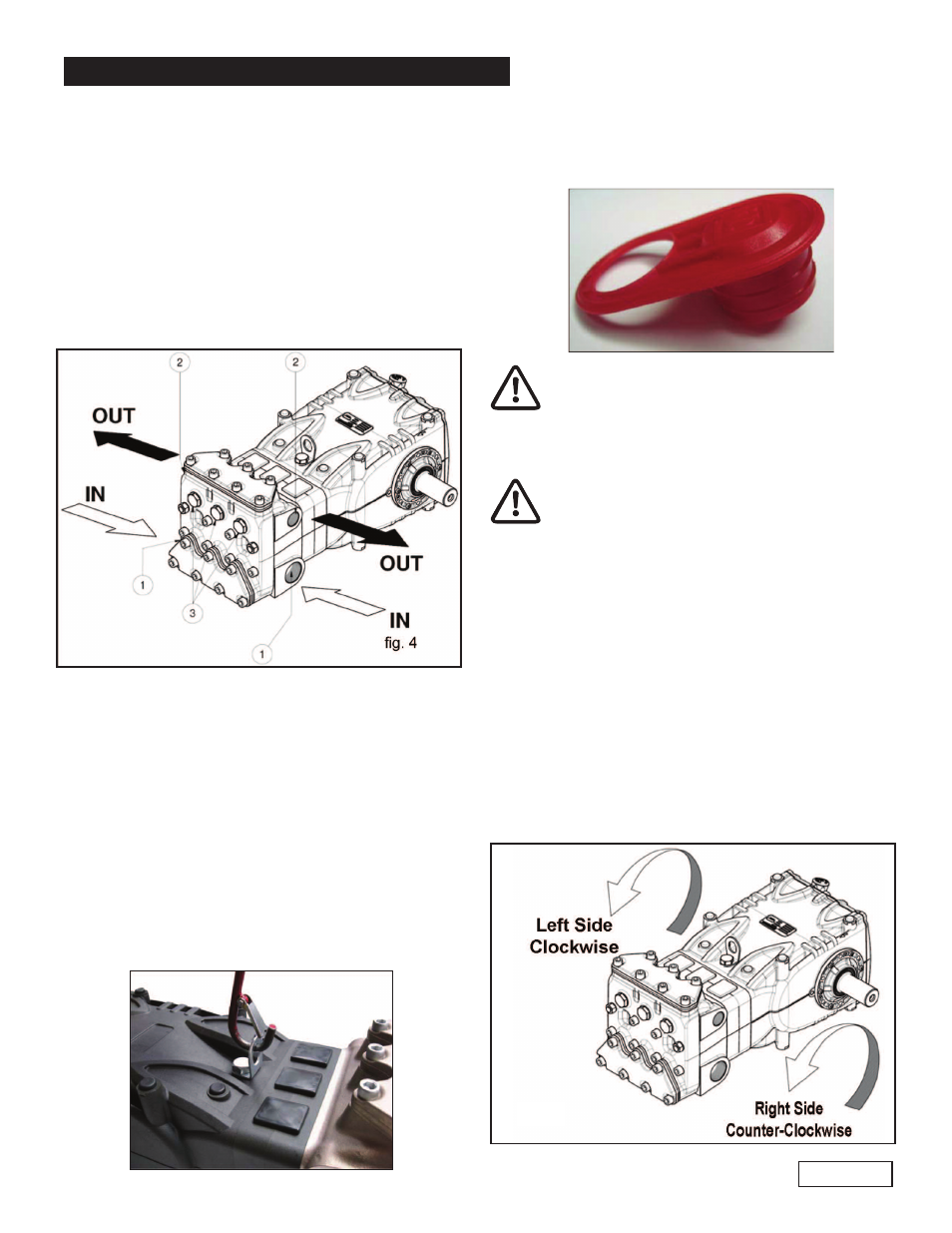

KFM Series pumps (see fig. 4) are provided with:

1. 2 inlet ports “IN”, 1-1/2”NPT.

The line can be connected to either of the two inlet

ports: the one not being used must be hermetically

sealed.

2. 2 outlet ports “OUT”, 1: NPT.

3. 3 auxiliary ports, 1/2” NPT, used for the pressure

gauge only.

Replace the oil cap (red), located on the rear

crankcase cover, with the oil dipstick and

check oil level. The oil dipstick must always be

accessible, even when the unit is assembled.

The pump’s shaft (PTO) must not be rigidly

connected to the motor unit. The following

transmission types are suggested:

• Hydraulic by means of a flange; for correct appli

cation, please contact the Customer Service

Department

• V-belts

• Cardan joint (please respect the maximum

working angles indicated by the Manufacturers)

• Flexible joint

9. PUMP INSTALLATION

9.1 Installation

The pump must be installed in a horizontal position using

the correct threaded feet M 16x1.5, fasten the screws with

a torque value of 155 ft. lbs. (210 Nm). The base must be

perfectly flat and sufficiently rigid in order to avoid bending

and misalignments on the pump/transmission coupling axis

due to the torque applied during operation. The unit must

not be rigidly fixed to the pavement, but requires the use of

anti-vibration elements. For special applications, please

contact the Customer Service Department.

The pump is equipped with a lifting eyebolt to facilitate

installation, as shown in the following figure.

In case of disassembly, to avoid letting dirt inside the front

part of the crankcase, close the threaded hole with the sup-

plied cap.

9.2 Direction of rotation

An arrow situated on the crankcase near the shaft indi-

cates the correct direction of rotation. Standing in front of

the pump head, the direction of rotation must be as shown

in fig. 5.

fig. 5