Kfm series, General pump – General Pump KFM Owner Manual User Manual

Page 12

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

Page 12

The suction line is connected and up to pres-

sure (see paragraphs 9.4, 9.5 and 9.6) the

pump must never run dry.

1. The suction line must be perfectly airtight.

2. All the On-Off valves between the pump and

the feeding source are completely open. The

delivery line must discharge freely in order to

allow the air in the pump to be expulsed

easily, thus facilitating pump priming.

3. All suction/delivery connections and fittings

must be correctly tightened.

4. Coupling tolerances on the pump/transmis-

sion axis (half-joint misalignment, Cardan

inclination, belt tightening, etc.) must remain

within the limits indicated by the transmission

Manufacturer.

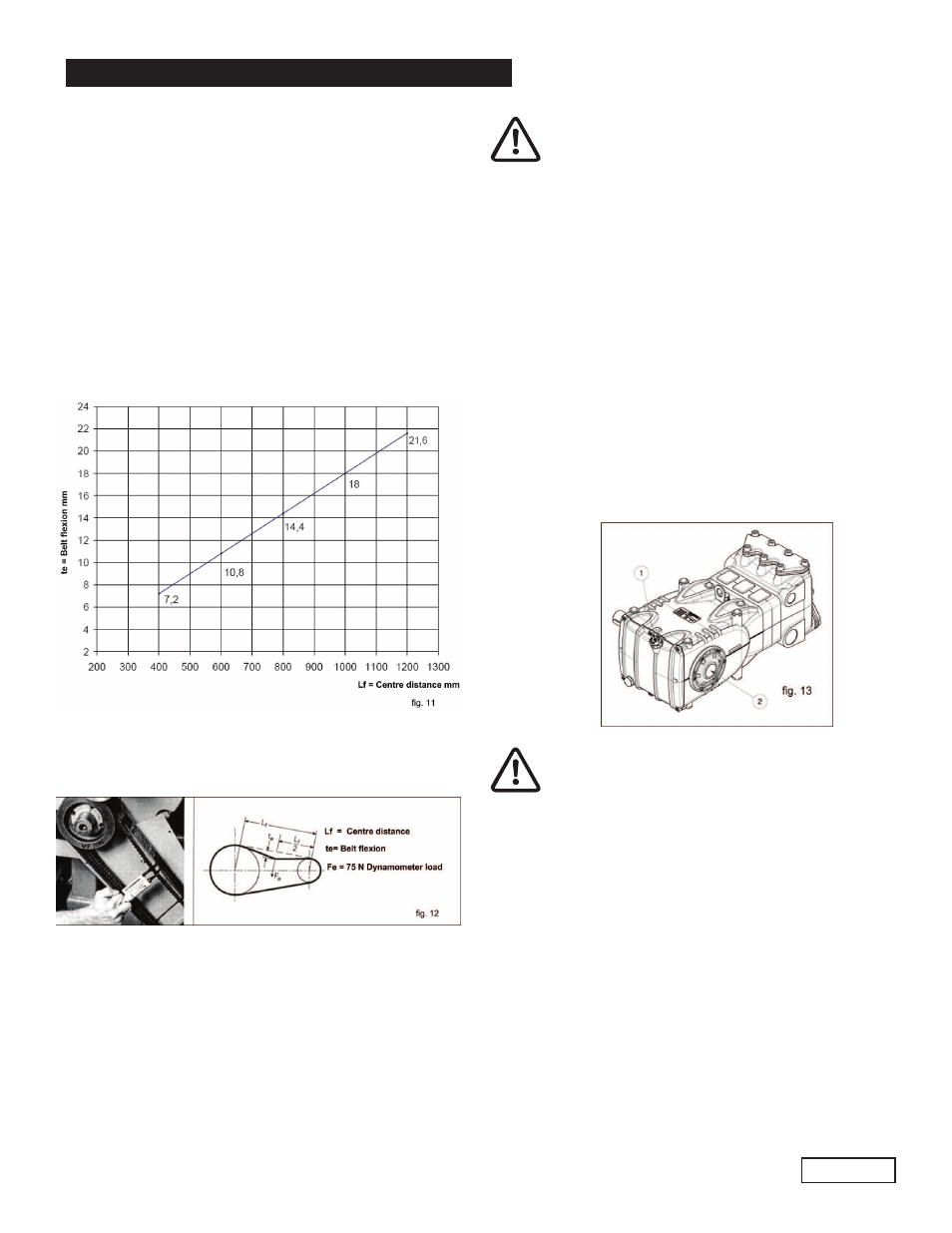

5. The pump’s oil level must be verified

using the correct dipsticks (position 1, fig 13),

and expecially by means of the oil sight glass

(2, fig. 13).

In case the pump has not run for a long period

of time, recover the correct operation of the

suction valves.

10. START-UP AND OPERATION

10.1 Preliminary Inspections

Before Start-up Be sure that:

9.11 Definition of belt static tension values

Static tension depends on:

a) the center distance between the two pulleys

(belt length)

b) The load due to the belt’s static tension

c) The number of belts

d) The angle of wrap of the smallest pulley

e) Average speed

f) Etc.

For belts with an XPB profile, the diagram in fig. 11 allows

to obtain the valued of the static tension that must be

applied vs. the center distance between pulleys.

Finally, given a distance between pulley centers of 600

mm and a load of 75 Nm a belt flexion “te” of around 10.8

will confirm the correct belt tension as shown in fig. 12.

NOTE: If not differently indicated by the belt manufacturer

the inspection of the correct tension value, and the related tension

adjustment if needed, is to be carried out after at least 30 minutes of

operation in order to obtain belt setting. The best efficiency and maxi-

mum duration is obtained with the correct tension value.

NOTE: If required, or during dormal maintenance, never replace a single

belt but the entire set.

10.2 Start-up

1. When starting the pump for the first time, check for

the correct direction of rotation.

2. The pump must be started off-load.

3. Verify correct feeding pressure.

4. During operation, check that the rotating speed does

not exceed the rated value.

5. Before putting the pump under pressure let it run for

at least 3 minutes.

6. Before stopping the pump, release the pressure by

acting on the adjustment valve or on any discharging

device.