Kfm series, General pump – General Pump KFM Owner Manual User Manual

Page 13

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

Page 13

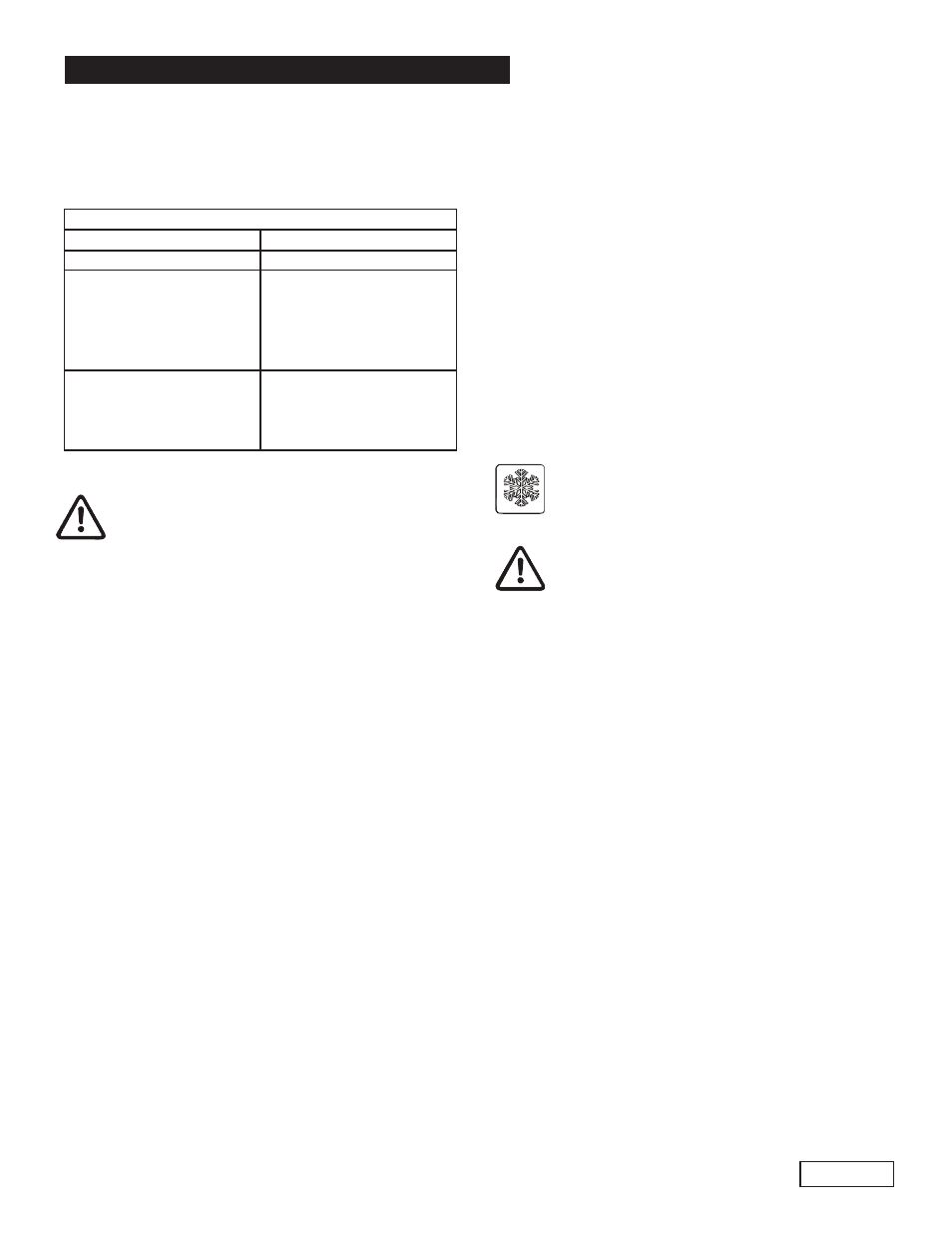

11. PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

EVERY 500 HOURS

EVERY 1000 HOURS

Check oil level

Change oil

Check / Replace:

• Valves

• Valve seats

• Valve springs

• Valve guides

Check / Replace:

• H.P packings

• L.P. packings

To guarantee pump reliability and efficiency, respect the

maintenance intervals as indicated in the table below.

12. STOPPING THE PUMP FOR LONG PERIODS

12.1 Inactivity for long periods

If the pump is started up for the first time after a long peri-

od from the shipment date, before starting operation

check the oil level, check the valves as indicated in

Chapter 10, and therefore follow the start-up procedures

described.

12.2 Filling the Pump With An Anti-Corrosion

Emulsion or Anit-freeze Solution

a)

Close the filter draining, if open.

b) Be sure that the connecting hose is clean, spread

with grease and connect it to the high pressure outlet

port.

c) Fit a suction hose to the membrane pump. Open the

pump suction connection and fit hose between it and

the membrane pump.

d) Fill the container with the solution/emulsion.

e) Put the free extremeties of the suction line and the

high pressure outlet hose inside the container.

f) Start up the diphragm pump.

g) Pump the emulsion until it comes out of the high

pressure hose.

f

ig. 14

In order to increase life of hydraulic compo-

nents of the fluid ends, a flushing operation

with clean water is recommended after every

daily operation

h) Continue pumping for at least another minute; if

needed, the emulsion can be reinforced by adding,

for example, Shell Donax

i) Stop the pump, remove the hose from the suction

connection and close it with a plug.

j) Remove the hose from the high pressure outlet port.

Clean, grease and plug both connections and the

hoses.

12.3 Hoses

a) Before greasing and protecting the hoses according

to the previously described procedure, dry the con-

nections using compressed air.

b) Cover with polyethelene.

c) Do not wrap them too tightly; be sure there is no

bending.

13. PRECAUTIONS AGAINST FREEZING

In areas and periods of the year where there is

risk of freezing, follow the instructions indicated

in Chapter 12 (see paragraph 12.2).

In the presence of ice, in no case must the

pump be started until the entire circuit has

been completely thawed out; not complying

with this indication may cause serious

damage to the pump.

14. WARRANTY TERMS

The duration and the terms of the warranty are contained

in the purchase contract. The warranty is void if:

a) The pump has been used for purposes that differ

from that agreed.

b) The pump has been fit with an electric or diesel

engine with performance greater than that indicated

in the table.

c) The required safety devices were un-adjusted or dis

connected.

d) The pump was used with accessories or spare parts

not supplied by General Pump.

e) Damage was caused by:

1) improper use

2) the non-observance of maintenance instructions

3) use not compliant with operating instructions

4) insufficient flow rate

5) faulty installation

6) incorrect positioning or sizing of the hoses

7) non-authorized design changes

8) cavitation