Kfm series, General pump – General Pump KFM Owner Manual User Manual

Page 7

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

Page 7

7.INFORMATION REGARDING PUMP USE

The KFM pump has been designed to operate

with high percentages of bentonite and/or poly-

mer up to a max. recommended density of 1.05

Kg/lt at max temperature of 104

0

F (40

0

C).

Other fluids may be used only upon the

approval of The Customer Service

Department

.

7.2 Max Flow Rate and Pressure Values

The performance values indicated in the catalog refer to

the maximum performance of the pump. Regardless of the

power used, pressure and maximum RPM values indicat-

ed on the plate may not be exceeded unless expressly

authorized by the Customer Service Department.

7.3 Lowest RPM

Any RPM value different from what is indicated in the per-

formance table (see chapter 5) must be expressly author-

ized by the Customer Service Department.

7.4 Recommended Lubricant Oil Types & Manufacturers

The pump is delivered with lubricant oil compliant with

room temperatures ranging between 32

0

and 89.6

0

F (0

0

and 30

0

C ). Some recommended lubricant types are indi-

cated in the table below; these lubricants are treated with

additives in order to increase corrosion protection and

resistance to fatigue. As an alternative, Automotive SAE

85W-90 gearing lubricants may also be used.

7.1 Bnetonite Temperature

The max bentonite temperature is 86

0

F (30

0

C). Nonetheless, it is possible to use the

pump at temperatures of up to 104

0

F (40

0

C)

for short periods of time. In this case we

advise consulting the Customer Service

Department.

BRAND

TYPE

GENERAL PUMP

SERIES 220

ARAL

Aral Degol BG220

BP

ENERGOL HLP 220

CASTROL

Hyspin VG 220, Magna 220

ELF

POLYTELIS 220

ESSO

NUTO 220

FINA

Cirkan 220

FUCHS

RENOLIN 220

MOBIL

DTE OIL BB

SHELL

TELLUS C 220

TEXACO

RANDO HD 220

TOTAL

CORTIS 220

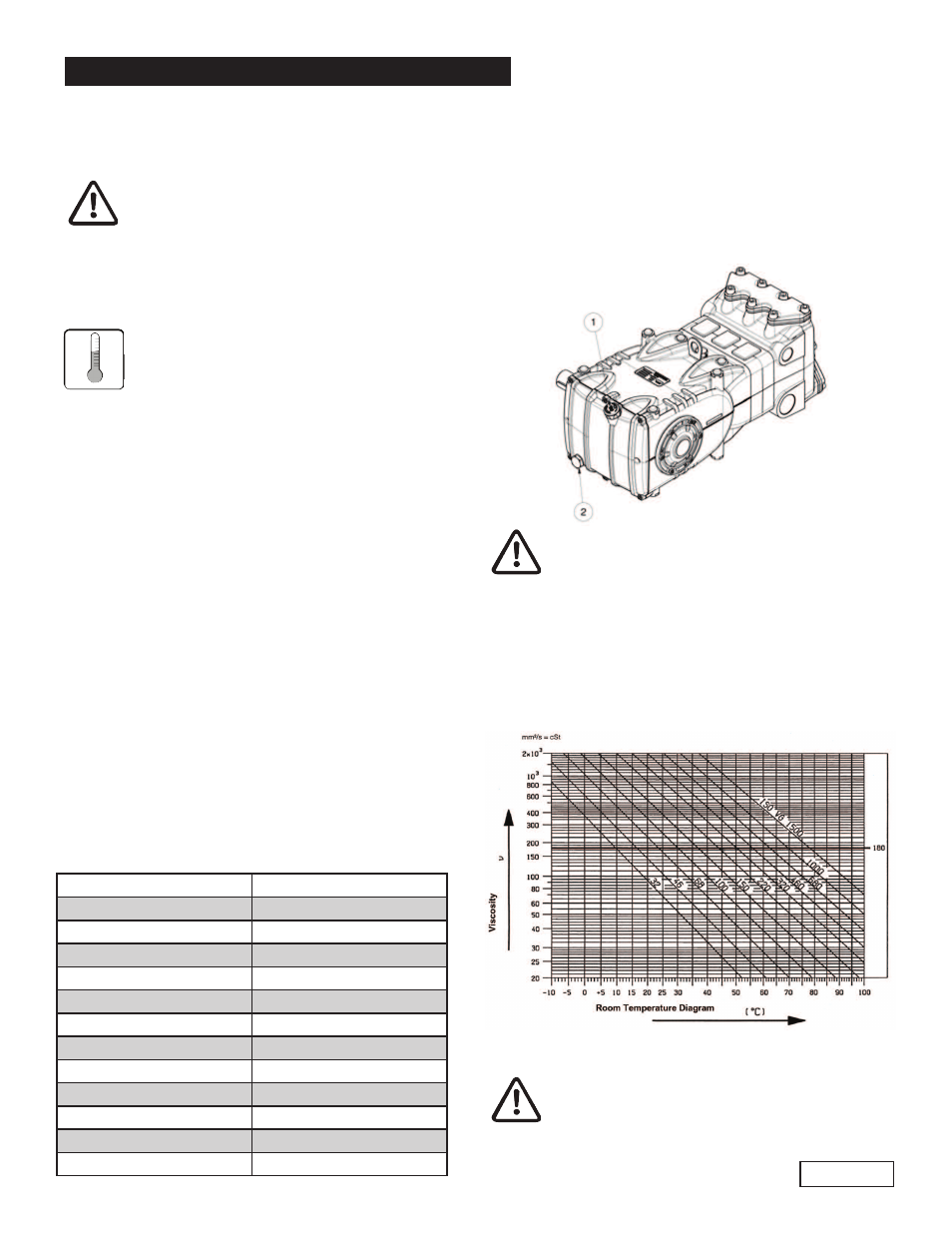

Check the oil level by using the oil level dipstick (1), fig. 3.

Refill if needed. Correct oil level inspection is done with the

pump at room temperature; oil is changed with the pump at

working temperature, by removing oil level dipstick (1) and

the plug (2), fig. 3. Oil inspection and changing is to be car-

ried out as indicated in the table in fig. 14, Chapter 11. The

amount required is 128.5 oz.(3.8 liters).

In any case, oil must be changed at least

once a year since it may deteriorate by

oxidation.

For room temperatures that differ from that men-

tioned earlier, follow the indications contained in

the diagram below, keeping in mind that the oil

must have a minimum viscosity of 180 cSt.

Exhausted oil must be collected in an appro-

priate recipient and disposed of in appropri-

ate locations. In absolutely no case may it be

dispersed into the environment.

VISCOSITY/ROOM TEMPERATURE DIAGRAM

fig. 3