Kfm series, General pump – General Pump KFM Owner Manual User Manual

Page 10

Page 10

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

9.7 Delivery Line

To obtain a correct delivery line, please comply with the

following installation instructions:

1. The internal diameter of the pump must allow to

guarantee correct fluid speed; see digram in

paragraph 9.8.

2. The first section of the hose connected to the pump

must be flexible in order to isolate pump vibrations

from the rest of the system.

3. Use high pressure hoses and fittings that guarantee

wide safety margins in any working condition.

4. Use pressure switches suitable for the pulsating loads

typical of plunger pumps.

5. In the design phase, take into proper account the

pressure drop along the line, since this causes a

reduction in usage pressure with respect to the value

measured at the pump.

7. If the pump pulsations are harmful for particular

applications, install an appropriately sized pulsation

dampener on the delivery line.

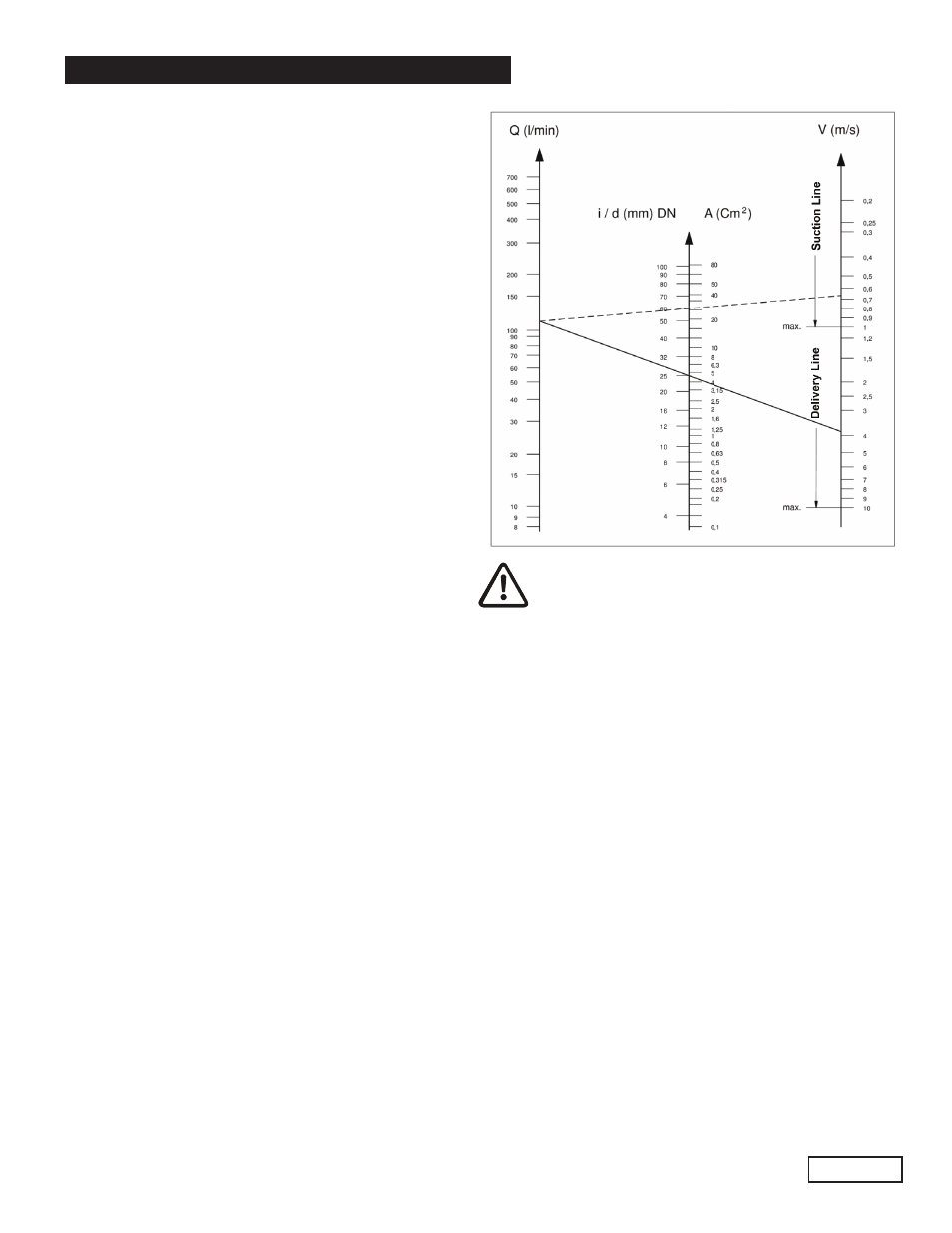

9.8 Internal Diameter of the Hose Line

To determine the internal diameter of the hose, please

refer to the following diagram.

Suction Hose

With a flow rate of ~30 GPM (113 l/mn) and bentonite

speed of 0.67 m/sec, the diagram line that connects the

two scales intersects the central scale, indicating the

diameters, at a value of ~ 2.4 inch (60 mm).

Delivery Hose

With a flow rate of ~30 GPM (113 l/mn) and bentonite

speed of 3.84 m/sec. The diagram line that connects the

two scales intersects the central scale, indicating the

diameters at a value of ~ 1 inch (25 mm).

Optimum speed values:

• Suction:

≤ 0.67 m/sec.

• Delivery:

≤ 3.84 m/sec.

The diagram does not take into account the hose

and valve resistance, the pressure drop due to the

pipe length, the viscosity and the temperature of

the pumped fluid. If necessary, contact our

Customer Service Department.