Kfm series, General pump – General Pump KFM Owner Manual User Manual

Page 4

Page 4

GENERAL PUMP

A member of the Interpump Group

KFM SERIES

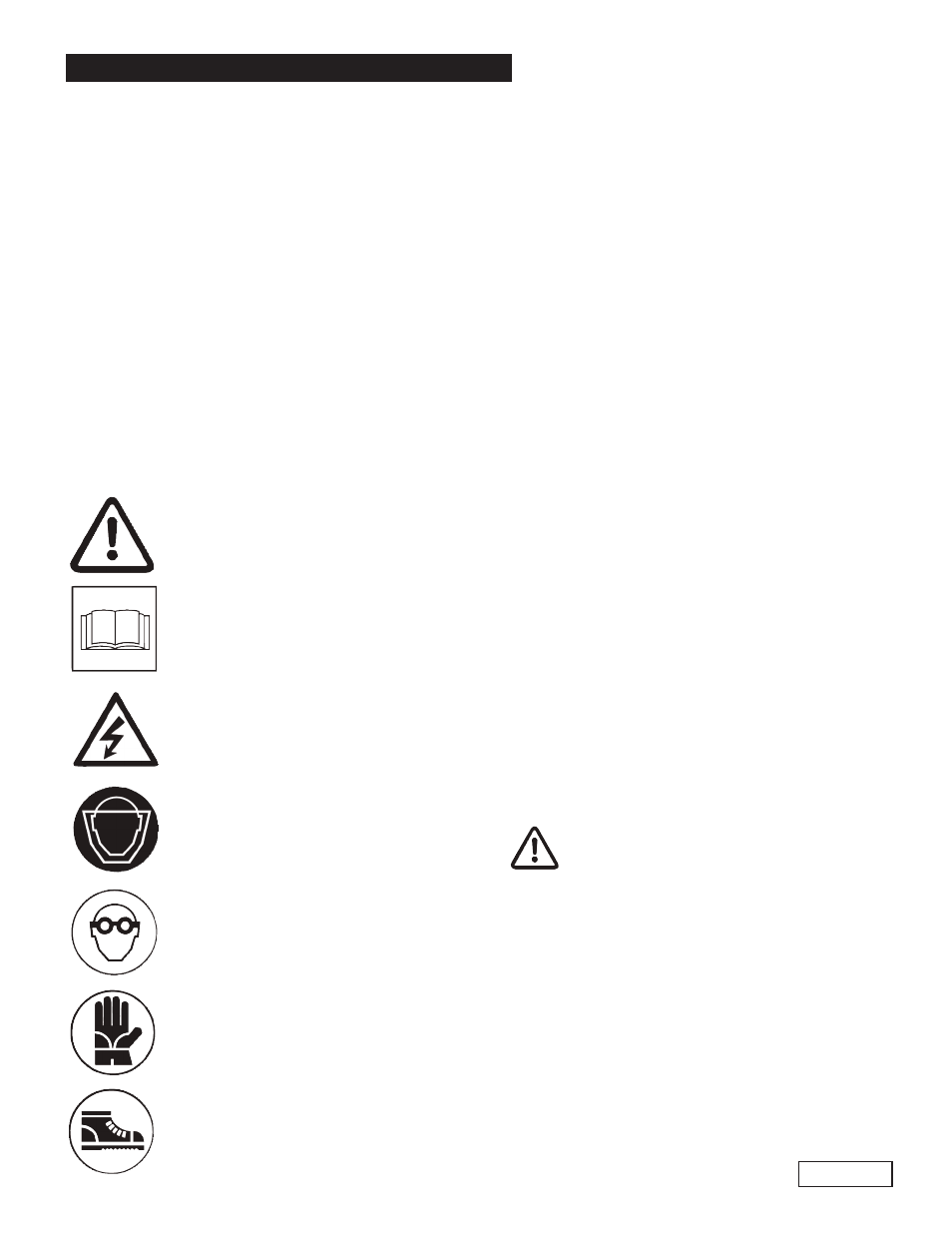

2. SYMBOL DESCRIPTIONS

Warning

Potential Danger

Danger

High Voltage

Danger

Wear protective mask

Danger

Wear goggles

Danger

Wear protective gloves

Danger

Wear protective boots

Read carefully and understand

the manual before operating

the pump

1. INTRODUCTION

This manual describes the use and maintenance

instructions of the KFM pump, and should be carefully read

and understood before pump operation.

Correct use and adequate maintenance will guarantee the

pumps trouble-free operation for a long time. General

Pump declines any responsibility for damage caused by

misuse or the non-observance of the instructions indicated

in this manual.

Upon receiving the pump, check that it is complete and in

perfect condition. Should anything be found out of order,

please contact us before installing and starting the pump.

3. SAFETY

3.1 General Safety Indications

The misuse of pumps and high pressure units, and the

non-observance of installation and maintenance instruc-

tions may cause severe injury to people and/or damage to

property. Anyone requested to assemble or use high pres-

sure units must possess the necessary competence to do

so, should be aware of the characteristics of the compo-

nents assembled/used, and must adopt all the necessary

precautions in order to guarantee maximum safety in any

operating condition. In the interest of safety, no precaution

that is reasonably feasible must be neglected, both by the

Installer and the Operator.

3.2 High pressure unit safety requirements

1. The pressure line must always be equipped with a

safety valve.

2. High pressure unit components, in particular

for those units working outside, must be adequately

protected against rain, frost and heat.

3. The units electrical parts must be adequately

protected from bentonite spray, and must comply with

the specific norms in force.

4. High pressure hoses must be correctly sized for the

unit’s maximum operating pressure, and must only be

used within the pressure range indicated by the hose

manufacturer. The same conditions apply to all other

unit accessories where high pressure is involved.

5. The extremeties of high pressure hoses must be

sheathed and fastened to a steady structure in order

to avoid dangerous whiplashes should they burst or

should their connections break.

6. Appropriate safety guards must be provided for the

pump transmission systems (joints, pulleys and belts,

auxiliary drives).

3.3 Safety During Operation

The working area of a high pressure system must be clear-

ly signalled. Access must be prohibited to non-authorized

personnel and, if possible, the area must be fenced in. The

personnel authorized to access this area must be previ-

ously trained, and informed about the risks that may arise

from failures or malfunctions of the high pressure unit.

Before starting the unit, the operator must check:

1. That the high pressure unit is correctly fed (see

paragraph 9.5).